Rear underbody for a vehicle

A body floor and rear technology, applied in the field of rear body floor, can solve the problem of large size of components and parts, and achieve the effects of reducing development cost, high torsional strength and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

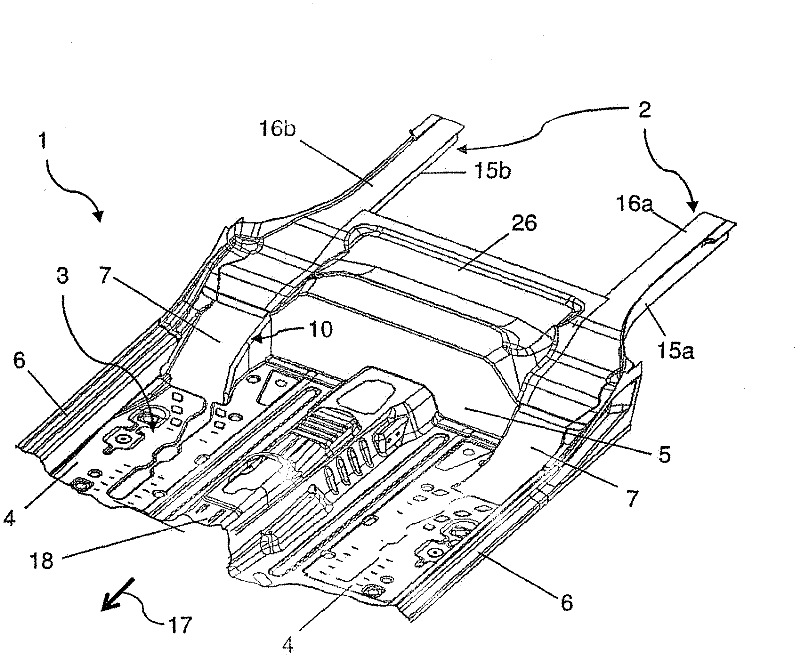

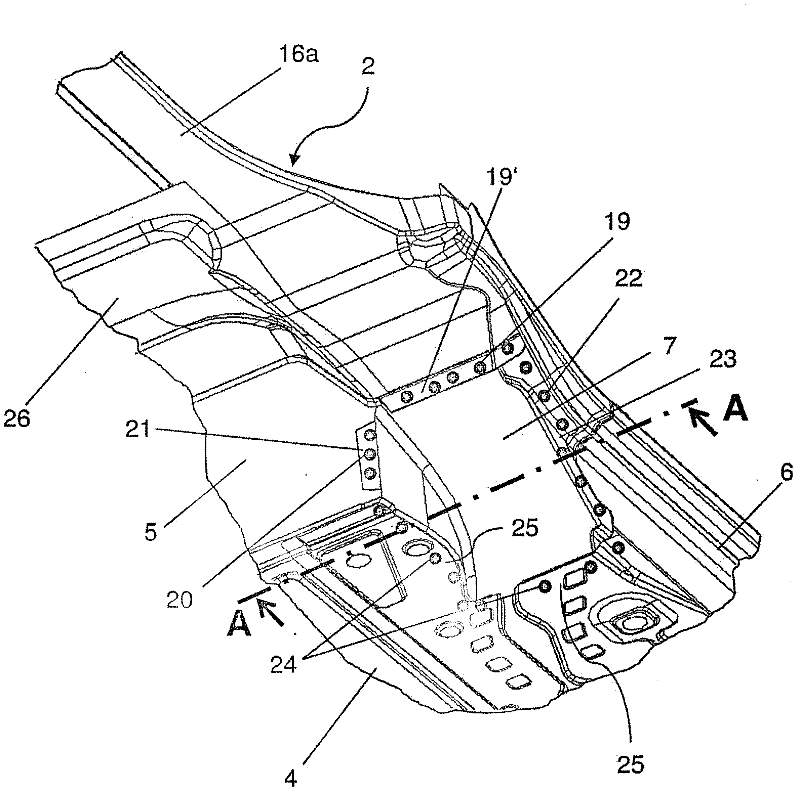

[0038] figure 1 A possible embodiment of a rear underbody 1 for a vehicle or motor vehicle, in particular a passenger car, is shown schematically. The rear underbody 1 is especially suitable for a four-seater vehicle, in particular a four-seater compact car.

[0039] The rear underbody 1 has a rear frame structure 2 and a floor structure 4 which forms a floor for a foot well 3 of the vehicle. Furthermore, the rear underbody 1 has a closure 5 delimiting the footwell 3 to the rear, which closure is formed by a so-called footboard.

[0040]Viewed in the direction of travel 17, the structures of the rear underbody 1 are arranged sequentially, the rear frame structure 2 is arranged behind the floor structure 4, wherein the floor structure 4 terminates at the footrest 5, which represents the footwell 3 the end. Viewed in the direction of travel 17 , the floor structure 4 can have, essentially in the central region, a central bracket or channel 18 which extends to the footboard 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com