Control synthetic method of high-visible-light-activity mixed crystal type BiVO4 photocatalysts

A technology of photocatalyst and synthesis method, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve the problems of no synthesis report, single monoclinic scheelite structure, etc., and achieve good results. Catalytic effect, controllable crystal structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

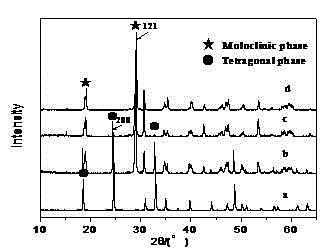

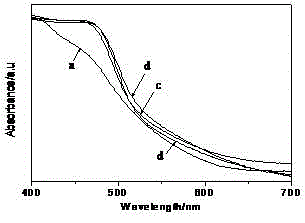

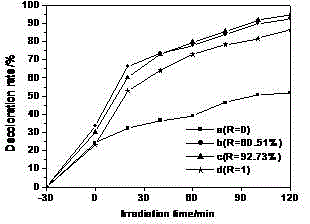

[0016] Embodiment 1: synthesize according to the following steps R BiVO = 0 4 That is, BiVO with pure tetragonal zirconium silicate structure 4 :

[0017] a) Weigh 0.9283g NH 3 VO 4 Dissolve in 10mL 2mol / L NaOH solution to make transparent solution A, weigh 3.8884g Bi(NO 3 ) 3 ?5H 2 O dissolved in 10mL 2mol / L HNO 3 A transparent solution B is made in the solution;

[0018] b) Gradually add the above transparent solution A to the transparent solution B dropwise under constant stirring to form a yellow suspension, continue stirring for 30 minutes after the addition is complete, and then adjust the pH of the system with 2mol / L NaOH solution to 2, continue to stir for 6h;

[0019] c) Transfer the above suspension to a stainless steel reaction kettle lined with white polytetrafluoroethylene, and put it in a thermostat at 120°C for hydrothermal treatment for 8 hours;

[0020] d) Extract the reaction product by filtration, wash the obtained yellow precipitate with deionize...

Embodiment 2

[0021] Embodiment 2: synthesize according to the following steps R =60.51% mixed crystal BiVO 4 :

[0022] a) Weigh 0.9283g NH 3 VO 4 Dissolve in 10mL 3mol / L NaOH solution to make transparent solution A, weigh 3.8884g Bi(NO 3 ) 3 ?5H 2 O dissolved in 10mL 3mol / L HNO 3 A transparent solution B is made in the solution;

[0023] b) Gradually add the above-mentioned transparent solution A into the transparent solution B dropwise under constant stirring to form a yellow suspension, continue stirring for 30 minutes after the addition is complete, and then adjust the pH of the system with 3mol / L NaOH solution to 4, continue to stir for 4h;

[0024] c) Transfer the above suspension to a stainless steel reaction kettle lined with white polytetrafluoroethylene, and put it in a thermostat at 140°C for hydrothermal treatment for 5 hours;

[0025] d) Extract the reaction product by filtration, wash the obtained yellow precipitate with deionized water and absolute ethanol for 2 to...

Embodiment 3

[0026] Embodiment 3: synthesize according to the following steps R =92.73% mixed crystal BiVO 4 :

[0027] a) Weigh 0.9283g NH 3 VO 4 Dissolve in 10mL 4mol / L NaOH solution to make transparent solution A, weigh 3.8884g Bi(NO 3 ) 3 ?5H 2 O dissolved in 10mL 4mol / L HNO 3 A transparent solution B is made in the solution;

[0028] b) Gradually add the above-mentioned transparent solution A to the transparent solution B dropwise under constant stirring to form a yellow suspension, continue stirring for 30 minutes after the addition is complete, and then use 4mol / L NaOH solution to adjust the pH of the system to 7, continue to stir for 2h;

[0029] c) Transfer the above suspension to a stainless steel reaction kettle lined with white polytetrafluoroethylene, and put it in a thermostat at 160°C for hydrothermal treatment for 4 hours;

[0030] d) Extract the reaction product by filtration, wash the obtained yellow precipitate with deionized water and absolute ethanol for 2 to 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com