Cement kiln tertiary air tube valve plate

A cement kiln and secondary air technology, applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of short service life and achieve long service life, easy replacement and maintenance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

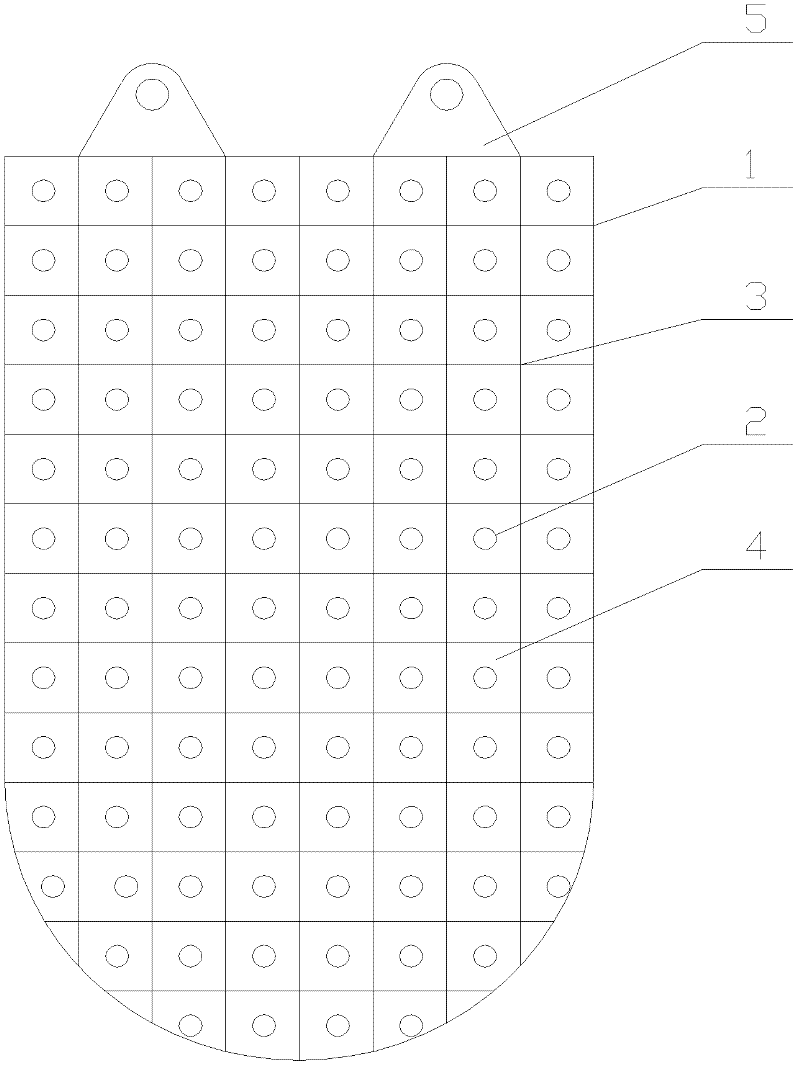

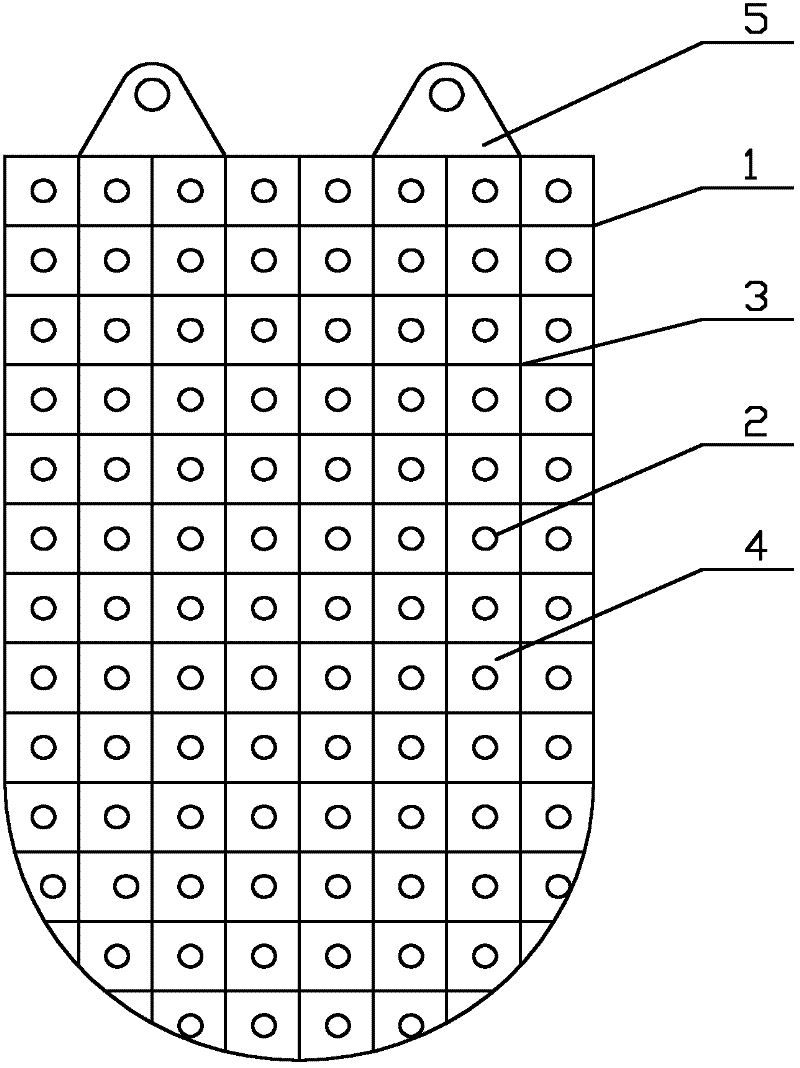

[0012] Such as figure 1 As shown, a cement kiln tertiary air duct valve plate includes a metal plate core 1, the metal plate core 1 is in a grid shape, and at least one lifting ring 5 is further provided on the metal plate core 1, and the grid shape It is a regular polygon 4, which can also be a shape. The regular polygon 4 ensures that there is no gap when the valve plate is poured, and the operation is simple and convenient to use. The regular polygon 4 is a square, and the square makes the casting effect best. The lifting ring 5 is welded to the metal The plate core 1 is welded to ensure that the hoisting ring 5 does not fall off and improve the product quality. There are two hoisting rings 5, and the two hoisting rings 5 are evenly distributed on the top of the metal plate core 1, so that the hoisting ring 5 is affected by Uniform force.

[0013] The metal plate core 1 is made of hot steel bars 3 into a square grid shape, two rings are uniformly welded on the top of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com