Tu's high-sensitivity overrunning clutch

An overrunning clutch, high-sensitivity technology, applied in the direction of clutches, one-way clutches, mechanical equipment, etc., can solve the problems affecting the response sensitivity of overrunning clutches, affecting the service life of overrunning clutches, damage to the surface of rollers or star wheels, etc., and achieve torque increase , Uniform stress, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

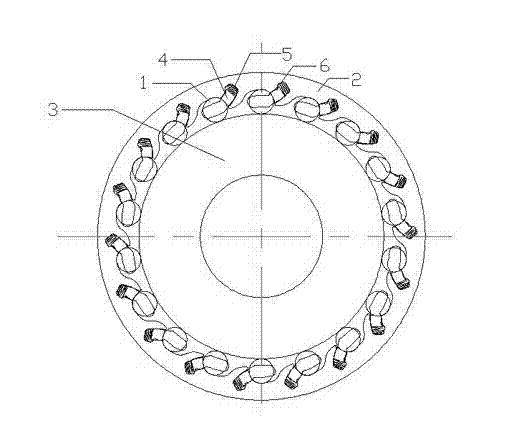

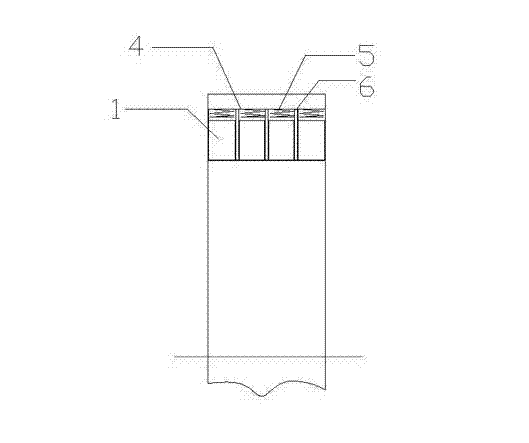

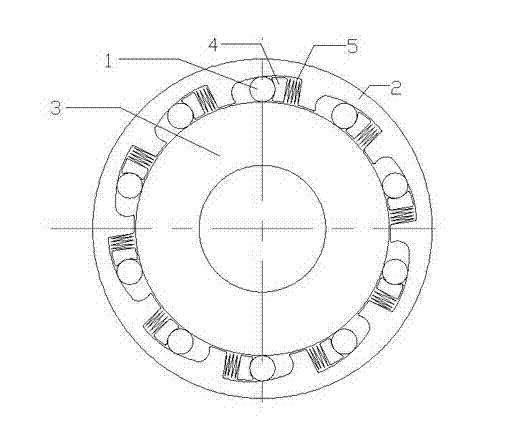

[0013] To understand the invention, see figure 1 , figure 2 , Tu's high-sensitivity overrunning clutch, including outer planet wheel 2 and inner planet wheel 3, can be set inside the outer planet wheel 2 or the inner planet wheel 3 outside the logarithmic spiral groove structure, the groove structure has multiple teeth Grooves, each row of top blocks 4 and springs 5 are respectively located in each tooth groove of the groove, and each tooth groove is arranged obliquely with the axis of the star wheel; each roller is a segmented structure, and each roller Spacer 6 is provided between.

[0014] The clutch of the present invention arranges the rollers, top blocks, and springs at a certain angle to the outside or inward along the axial direction of the outer star wheel or the inner star wheel, thereby reducing the perimeter distance occupied by the top block and the spring. More rollers can be arranged, which greatly increases the torque that Tu's high-sensitivity clutch can with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com