High-pressure dirt flushing multi-tube pass shell-and-tube heat exchange equipment and high-pressure dirt flushing method

A shell-and-tube heat exchange and multi-tube pass technology, which is applied to lighting and heating equipment, flushing, cleaning heat transfer devices, etc., can solve problems such as increased pump consumption, damage to heat exchange equipment, limited water volume and flow rate, etc., and achieves improved The effect of washing speed, reducing excess area, and long-term efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

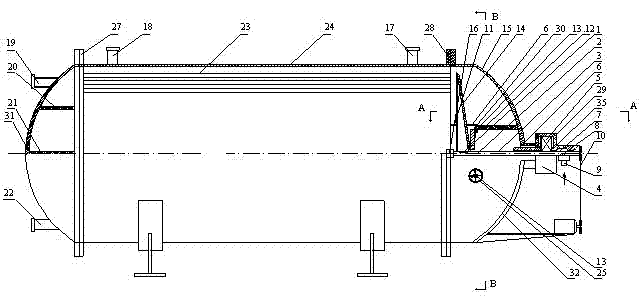

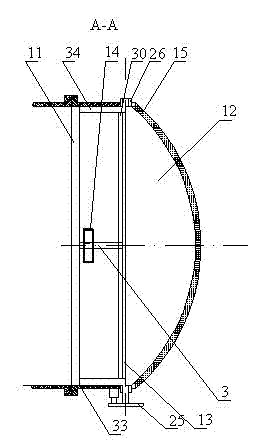

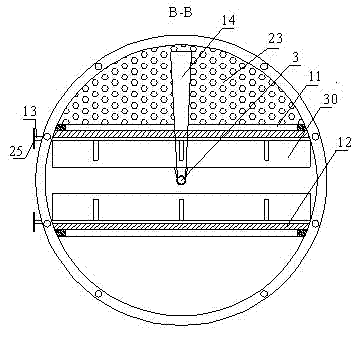

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0017] The multi-tube shell-and-tube heat exchange equipment for high-pressure flushing of the present invention mainly consists of a hollow main shaft 3, a bearing seat 4, a first bearing 5, a sealing gasket 6, a chain transmission device 10, a flushing nozzle 14, a second bearing 16, a casing body 24, left tube plate 27, right tube plate 28, joint 29, and folded and sealed tube-side partition 30; wherein: the two ends of the shell 24 are respectively connected to the left head 31 and the right head 32 through flange bolts; The right head 32 is fixedly connected by the cylindrical cylinder 33 and the arc-shaped head 15, and the left and right tube sheets 27 and 28 are consolidated in the shell 24; the heat exchange tube bundle 23 is welded to the tube sheet according to the design requirements of the heat exchanger 27,28; the housing is provided with inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com