Foam launching device

A launching device and foam technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as easy damage and difficult cleaning, and achieve the effects of preventing wear and deformation, reducing costs, and preventing pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

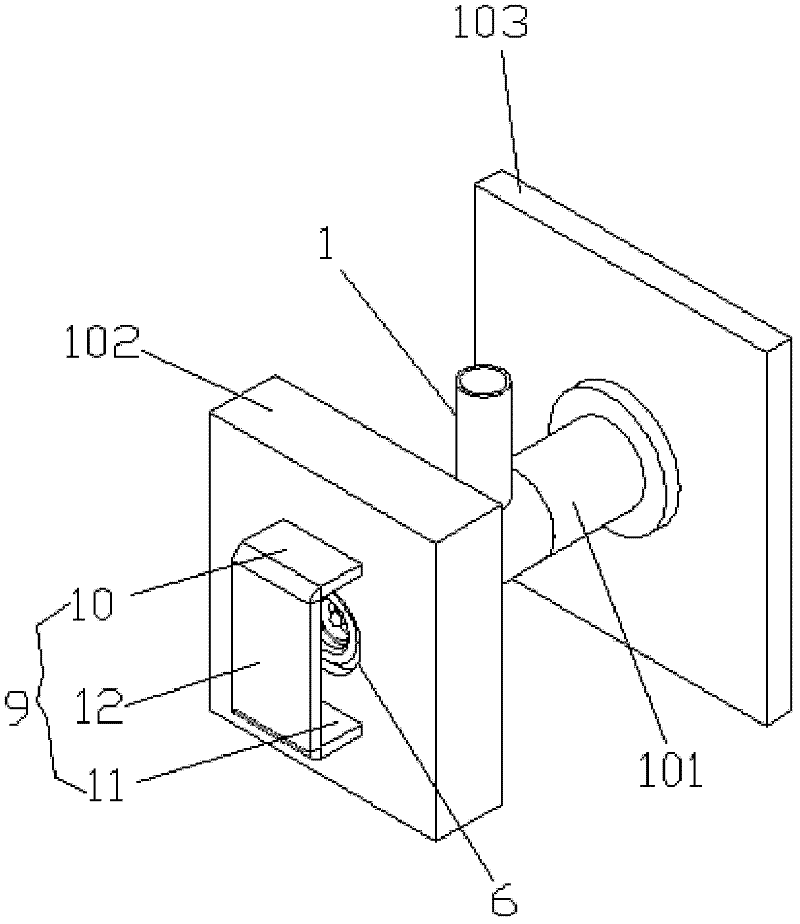

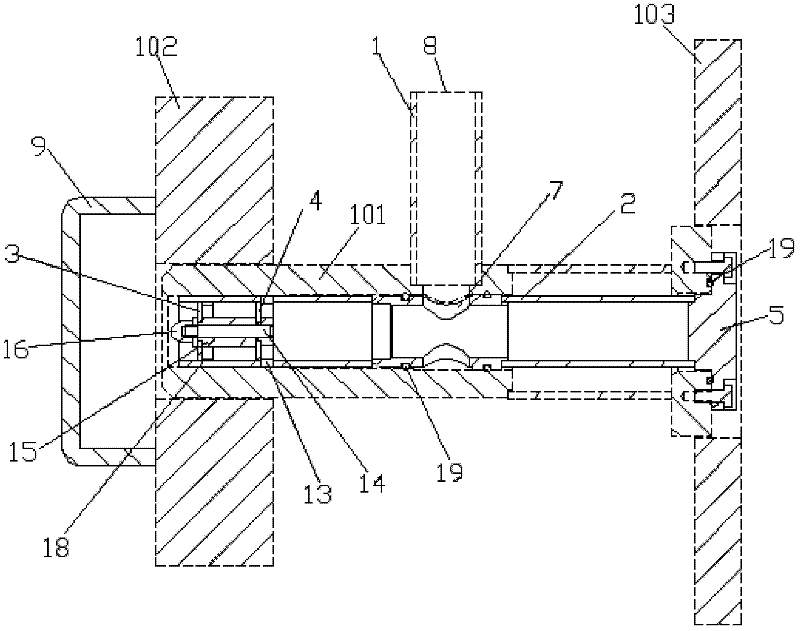

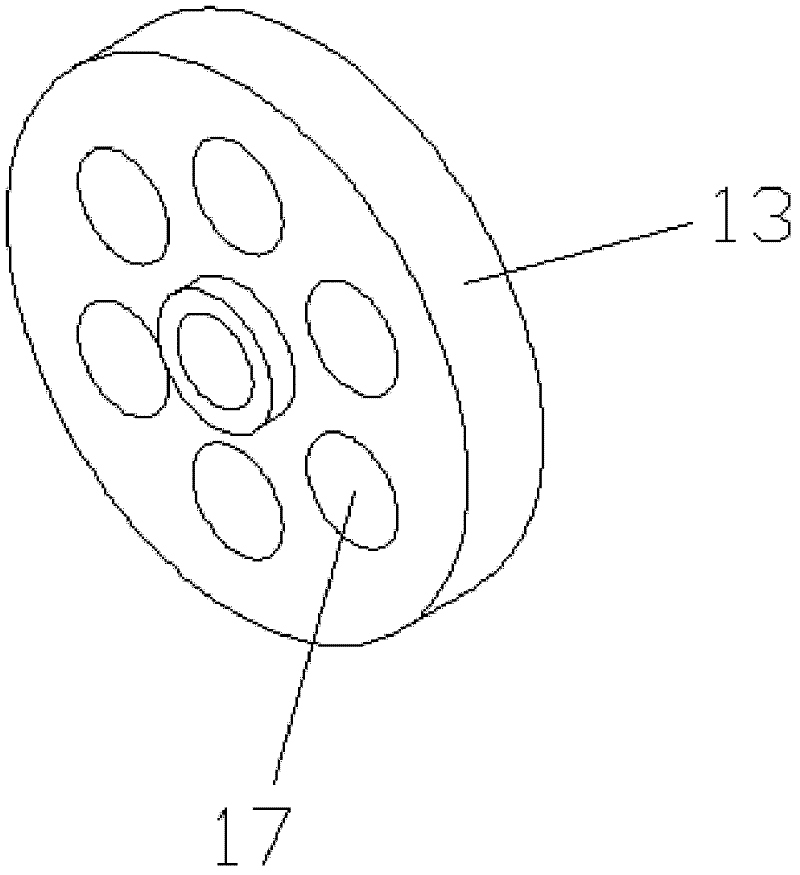

[0030] A kind of foam launching device, comprises injection pipeline 1, injection pipeline 2, first rubber cover 3, second rubber cover 4 and rear cover 5, and described injection pipeline just is arranged in the embedded pipeline 101 of shield machine and its two The ports are respectively connected to the cutterhead front panel 102 and the cutterhead rear panel 103; the centers of the first rubber cover and the second rubber cover are respectively spaced and fixed in a port close to the cutterhead front panel of the injection pipe The foam injection port 6 is formed, and the outer peripheral surfaces of the first rubber cover and the second rubber cover are just in contact with the inner surface of the injection pipe; On the end face: an opening 7 is provided on the side of the injection pipe, and a foam injection port 8 is formed at one end of the injection pipe, and the other end communicates with the opening. When in use, the foam is injected through the foam injection po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com