Self compensation floating swing arm independent suspension system

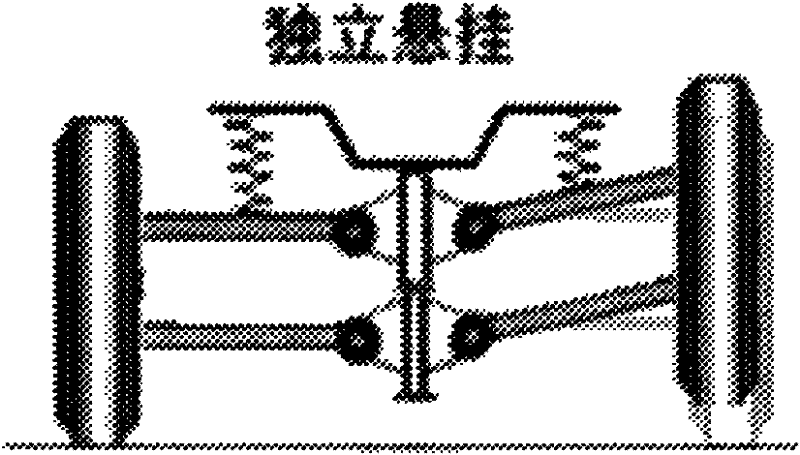

An independent suspension and self-compensation technology, applied in the interconnection system, suspension, elastic suspension, etc., can solve difficult vehicle handling, stability, comfort and safety, large frictional resistance between sleeve kingpins, The anti-rolling effect is not obvious, etc., to achieve ideal stability, no impact on suspension performance, and ideal comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Basic type, such as Figure 9, single group, horizontally placed, composed of floating swing arm (405), compensation mechanism (400), steering knuckle (410), and positioning shock absorber (411), the structure is the simplest, and the basic performance fully meets the requirements. performance, the swing arm can be widened or directly designed as an A shape to increase strength.

Embodiment 2

[0064] commonly used, such as Figure 10 The two sets of devices are distributed at 90 degrees, and the force is reasonable and the structure is relatively simple. The vertical swing arm (405) and compensator (400) only bear the tension when braking or when the wheel encounters resistance, so it can be smaller. to reduce mass

Embodiment 3

[0066] flexible arrangement, such as Figure 11 , installed in any direction perpendicular to the plane of the car body, similar to the basic type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com