Active electromechanical suspension system for a chassis of a motor vehicle

A suspension system and active suspension technology, applied in the direction of suspension, interconnection system, elastic suspension, etc., can solve the problems of increased cost and technical-economic implementation doubts, and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

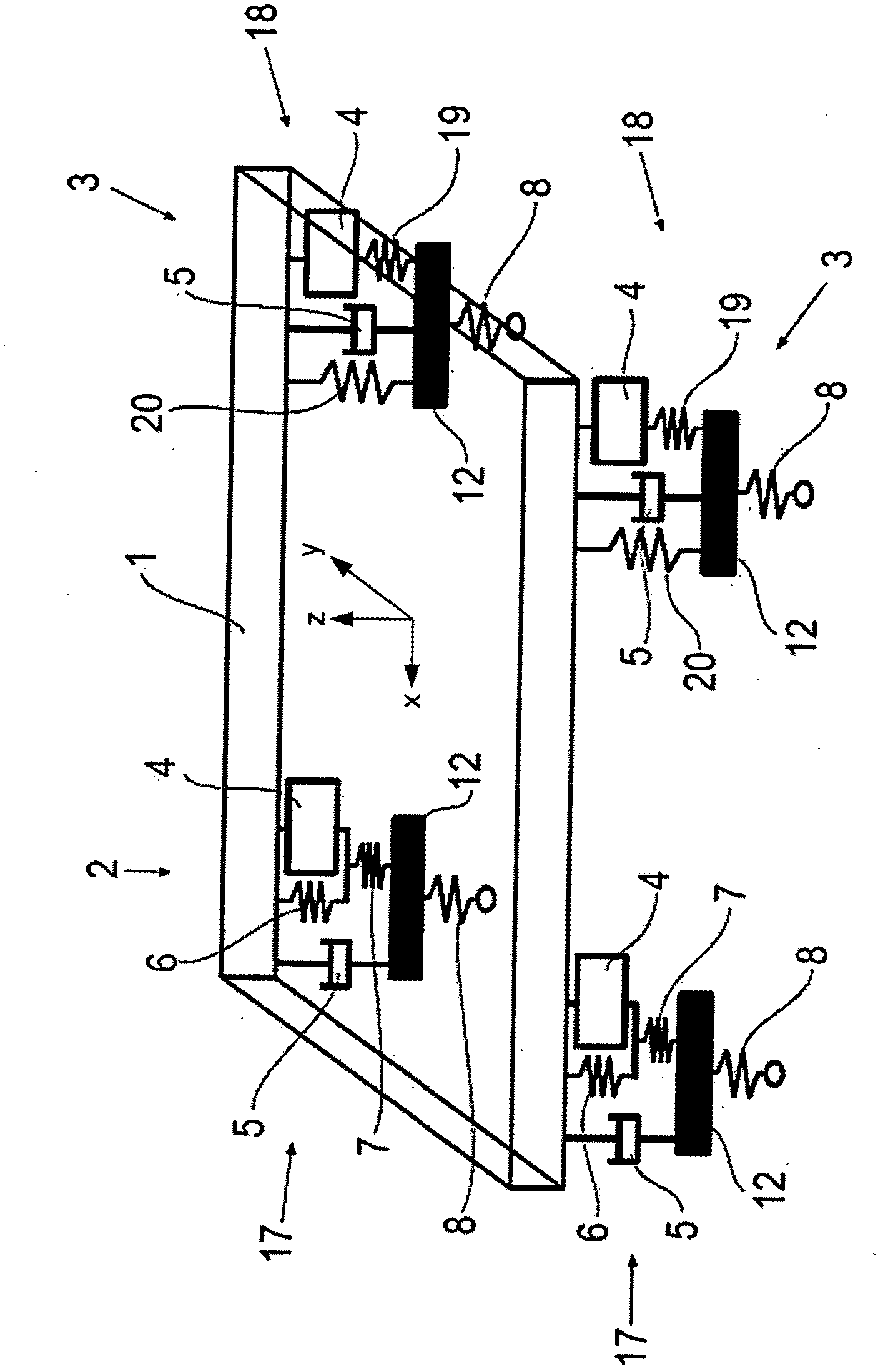

[0024] figure 1 The vehicle body 1 or a part of the vehicle body is schematically shown in . Here, the vehicle body 1 is connected on the left to the spring strut 17 and on the right to the spring device 18 . For ease of viewing, the associated axles and wheels are not shown. However, it should be noted that only the spring struts 17 or spring devices 18 and the respective wheels are always used on an axle.

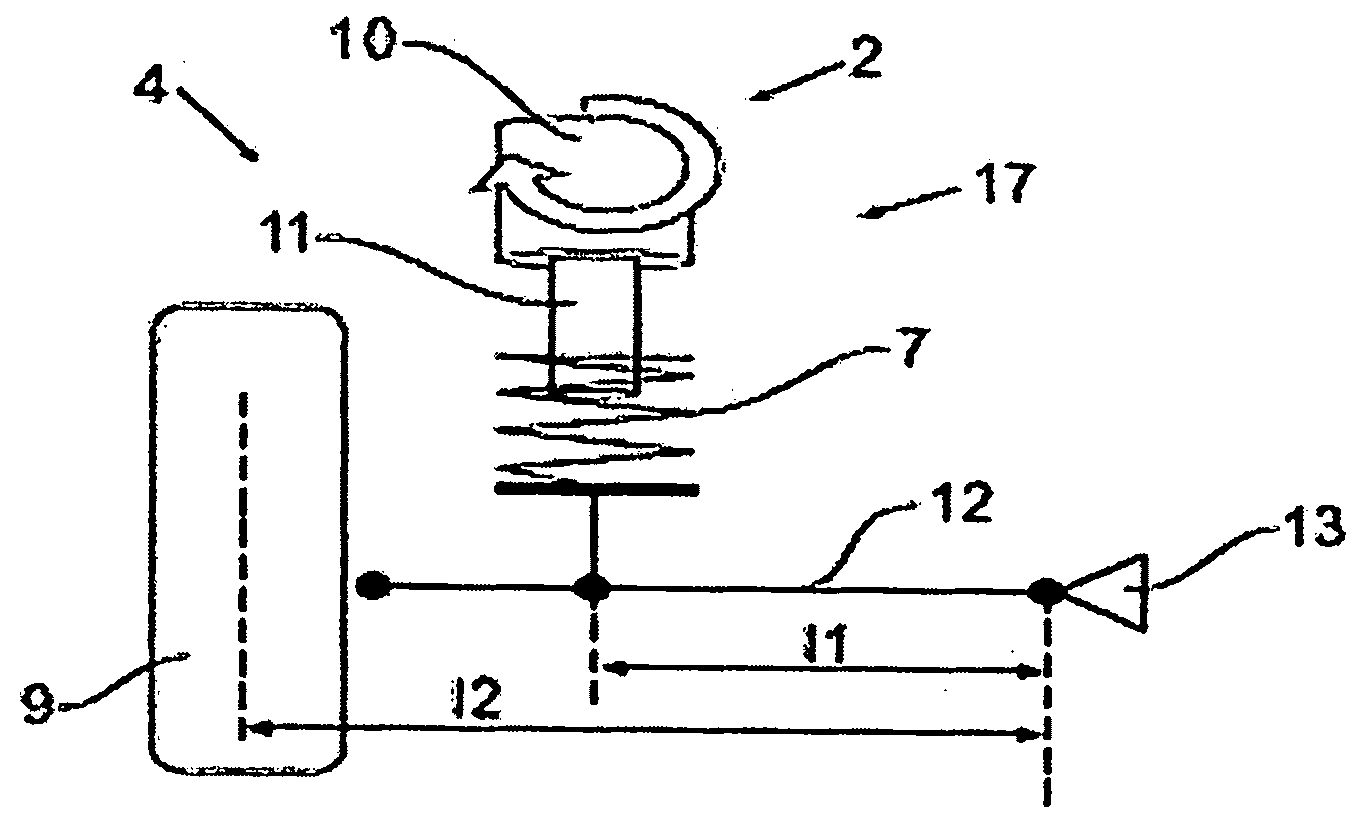

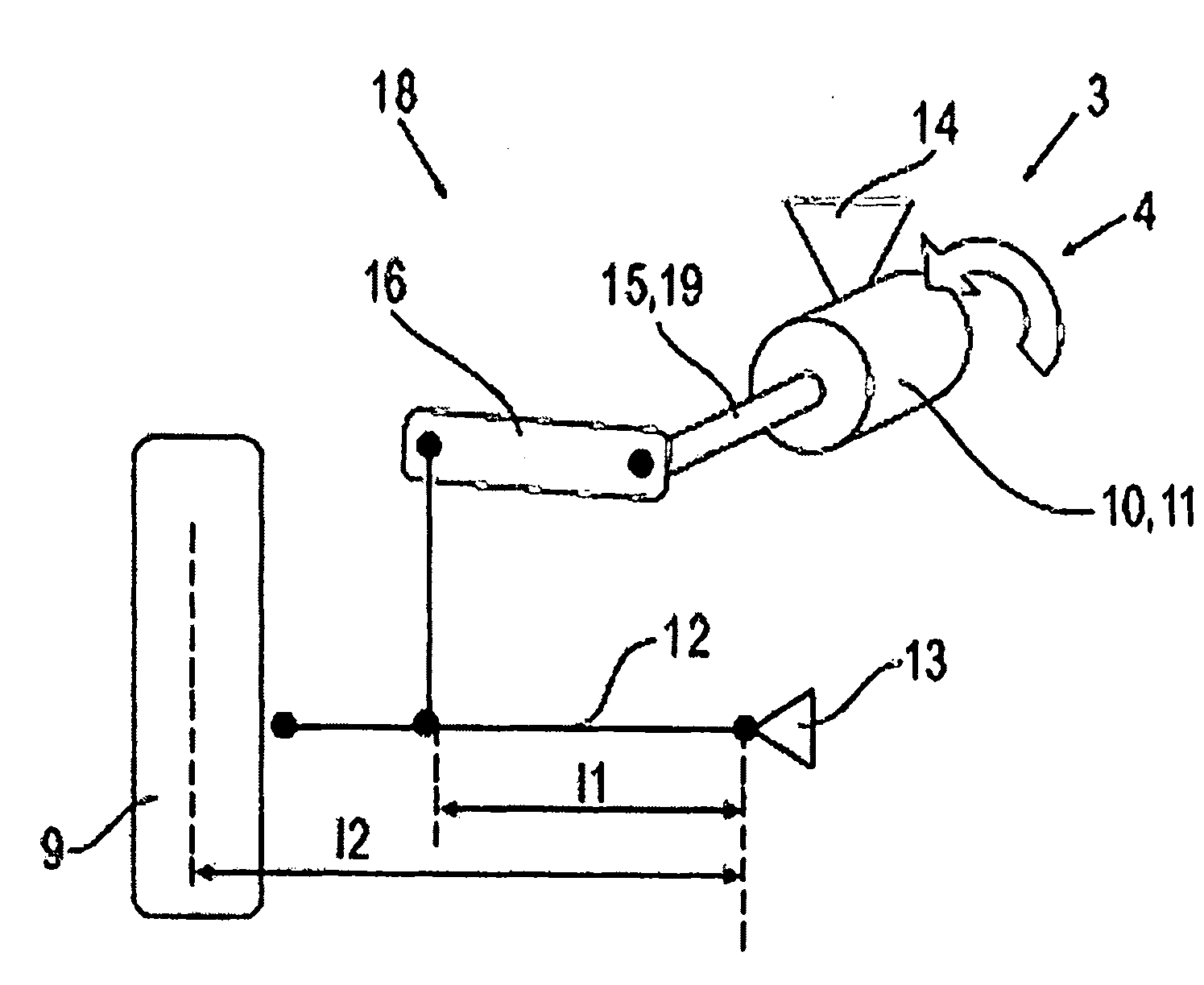

[0025] The basic structure of the spring strut 17 used for the first axle is, for example: the first spring 6 and the second spring 7 are connected to each other in a series structure, wherein the free end of the first spring 6 is directly or indirectly connected to the vehicle body 1 connected, and the free end of the second spring 7 is connected with the suspension arm 12 or the hub bracket. A hydraulic damper 5 is arranged parallel to the first spring 6 and the second spring 7 . Below the spring 6 , the spring 7 and the shock absorber 5 , the wheel suspension is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com