Wiring terminal structure

A technology of terminal blocks and lugs, which is applied in the direction of electrical connection seat, clamping/spring connection, multi-core cable end parts, etc. The effect of disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

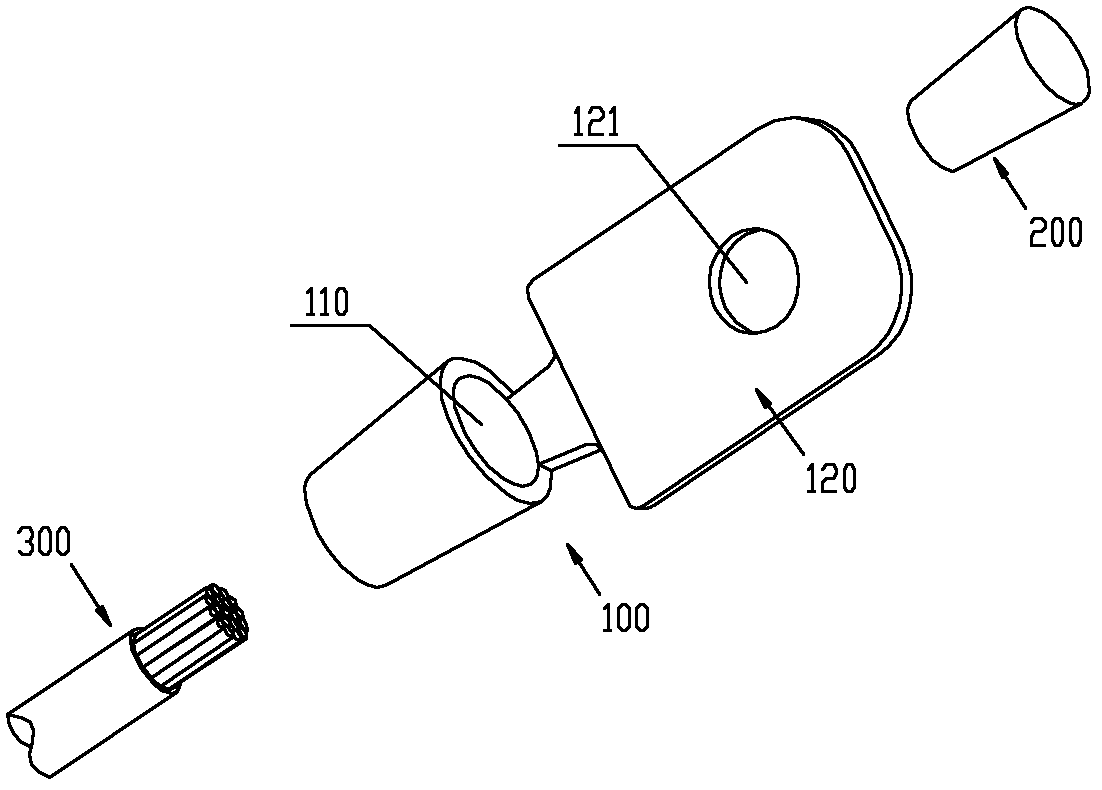

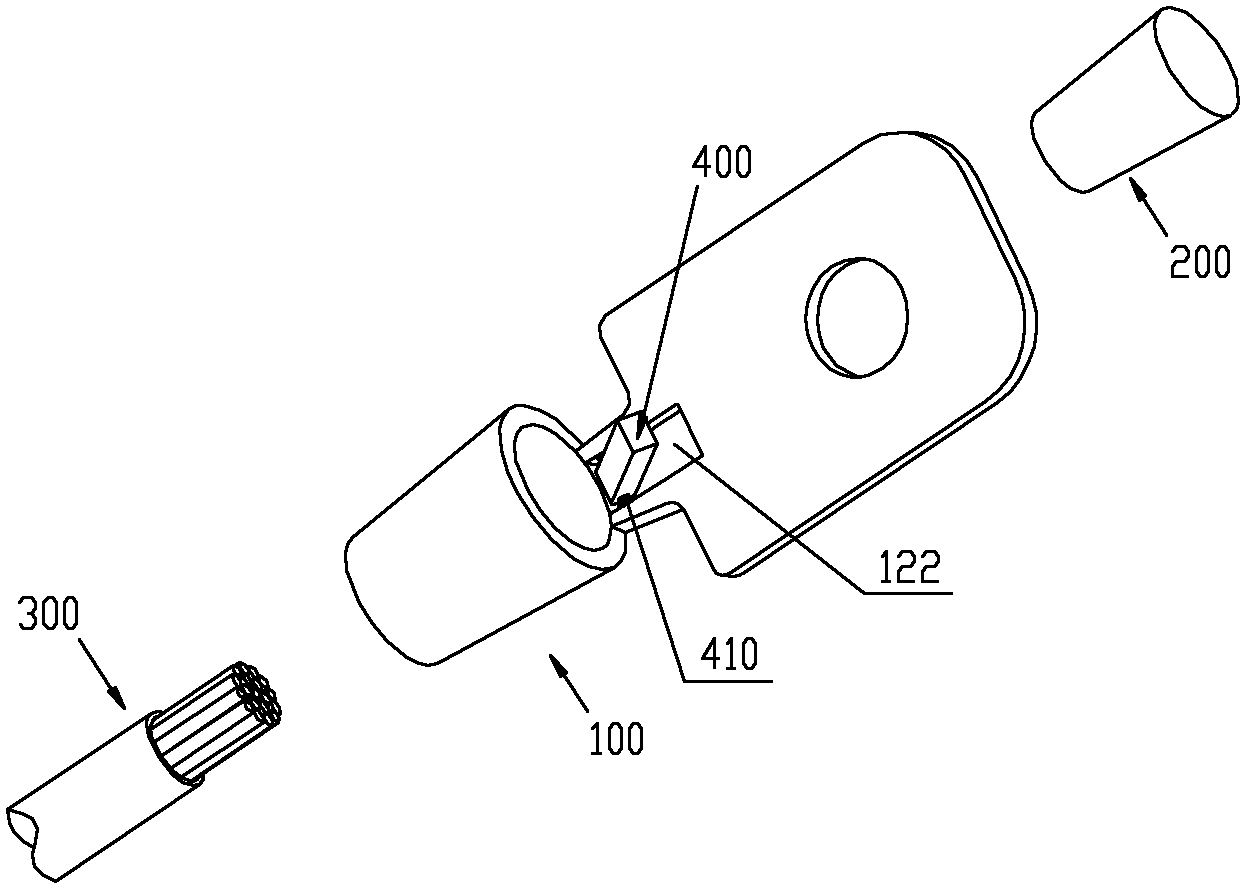

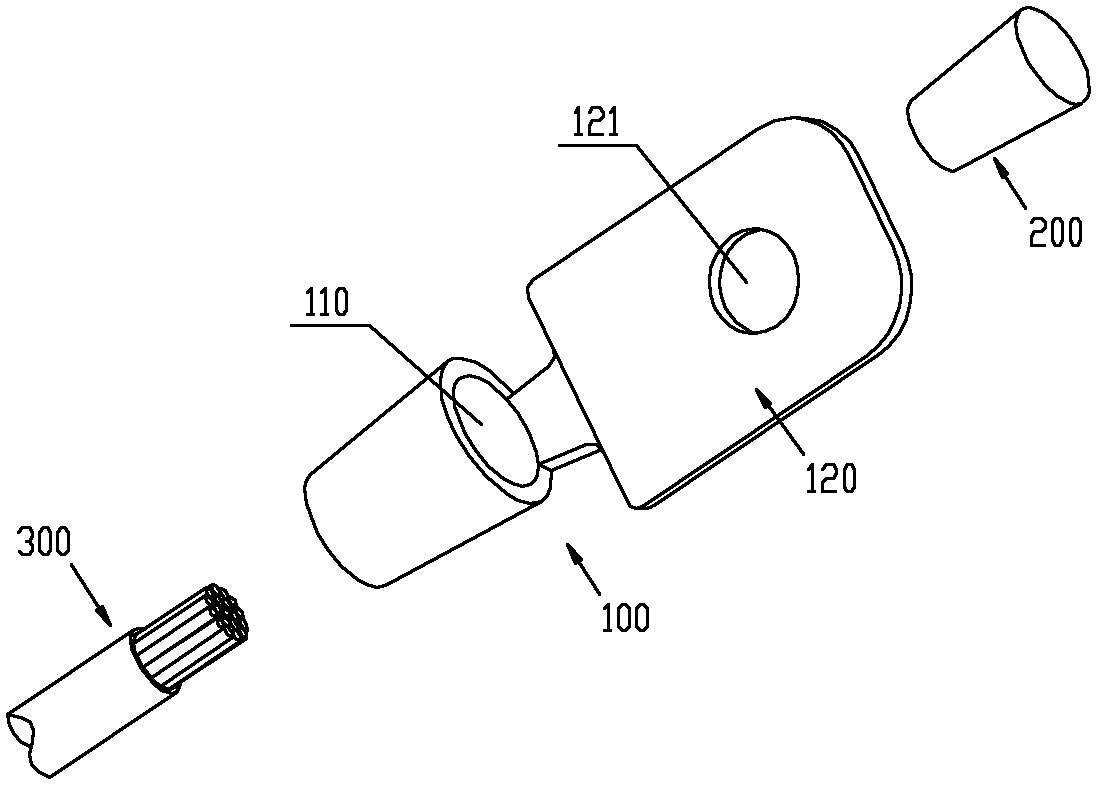

[0019] see figure 1 , a connection terminal structure, including a connection terminal 100 with a tapered through hole 110 in the center and a tapered pin 200 disposed in the tapered through hole, the tapered pin 200 matches the tapered through hole 110 of the connection terminal 100 .

[0020] A terminal piece 120 with a circular through hole 121 is provided at the end of the large hole of the tapered through hole of the terminal 100 .

[0021] The wiring piece 120 is integrated with the wiring terminal 100 . Of course, according to actual assembly requirements, the lug 120 and the connection terminal 100 can also be designed as a hinged two-part structure.

[0022] Wherein, the cross-section of the tapered through hole 110 of the termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com