Improved upward and downward compression mechanism of keyhole machine tool

A technology of pressing structure and machine tool, applied in the direction of cloth pressing mechanism, sewing machine components, textiles and papermaking, etc., can solve the problems of extremely high requirements of assemblers, difficult to achieve good results, difficult adjustment, etc., to reduce assembly requirements and Debugging difficulty, improving assembly and debugging efficiency, and good effect of pressing and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

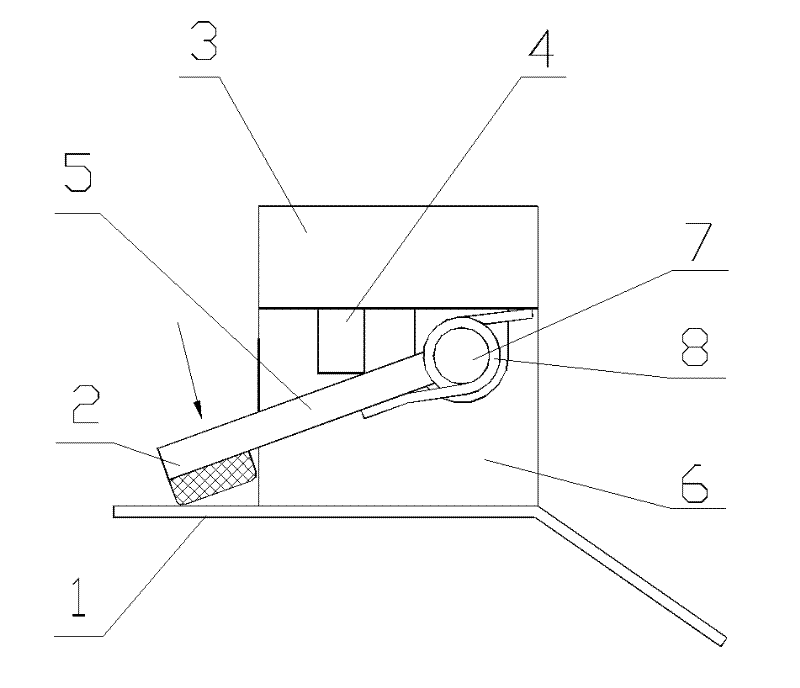

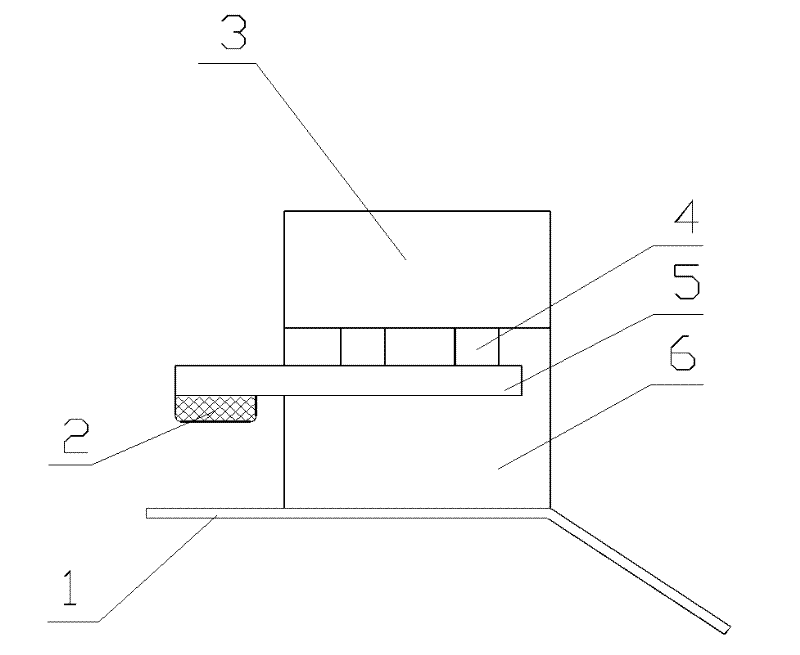

[0027] Figure 1~2 Among them, the structure of the existing upper and lower pressing mechanism is: the lower part is a horizontally fixed support plate 1, the upper part is a rectangular pressing plate 5, and one side of the pressing plate 5 is installed on the upper and lower pressing mechanism through a rotating shaft 7. On the support 6, a torsion spring 8 is arranged between the pressing plate 5 and the rotating shaft 7, and a cylinder 3 is arranged above the side of the arm of the pressing plate 5, and the cylinder piston rod 4 presses against the pressing plate 5 downwards. When clamping is required, the piston rod 4 of the cylinder 3 stretches out downwards, pushes the arm side of the pressing plate 5 to rotate and press down, and compresses the cloth that needs to be opened, such as figure 2 As shown; when the cloth needs to be loosened, the cylinder piston rod 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com