Integral carrier roller for belt conveyor

A belt conveyor, the overall technology, applied in the direction of conveyor objects, rollers, transportation and packaging, etc., can solve the problems of unequal contact area and bearing weight, troublesome disassembly, installation and debugging, inconsistent wear, etc., to achieve light weight , easy maintenance and replacement, and the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

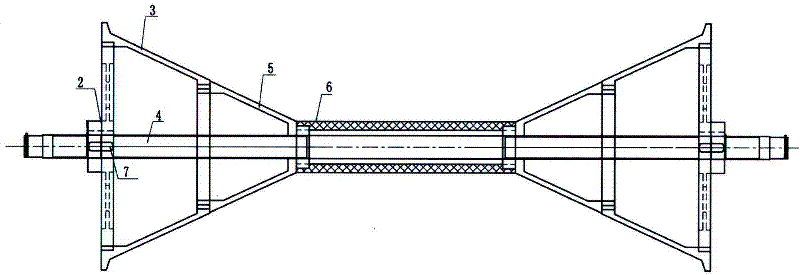

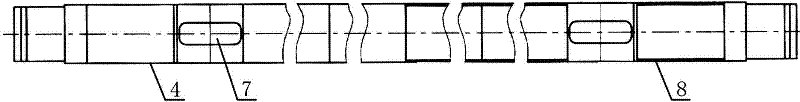

[0026] Such as figure 1 One of the integral rollers of the belt conveyor, the multi-section hollow roller is coaxially connected with the shaft roller 4, and the multi-section hollow roller has a shape with two ends high and the middle low. This structure can ensure the synchronous operation of the idler roller and the conveyor belt, and the shaft roller as a whole can also ensure the load-bearing compared with the suspended hinged idler roller. The rollers are relatively easy to remove, install and replace.

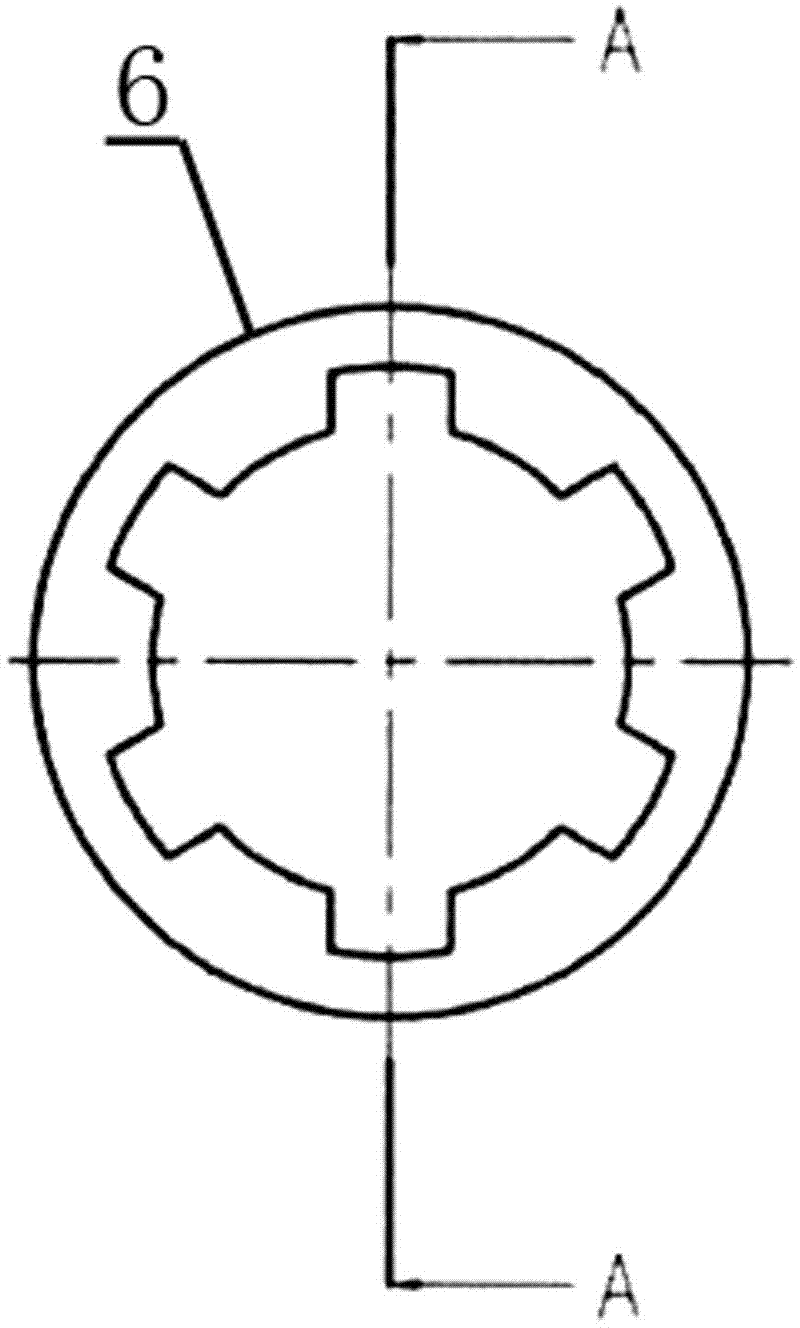

[0027] The multi-section hollow roller is composed of side baffles 2 on both sides, tapered sections on both sides and sleeves 6 in sequence. The hollow roller adopts a multi-section structure, so that the worn section can be easily replaced after the section wears out, such as the first tapered section in this example, thereby effectively reducing the overall use cost.

[0028] Such as figure 1 , Figure 7 and Figure 8 Among them, the side baffle plate 2 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com