Automobile oil filler cap assembly

A fuel filler cap and fuel filler technology, applied in the field of auto parts, can solve problems such as uncoordinated shapes, uneven distances, affecting structural durability, etc., and achieve the effect of avoiding closing difficulties and ensuring beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

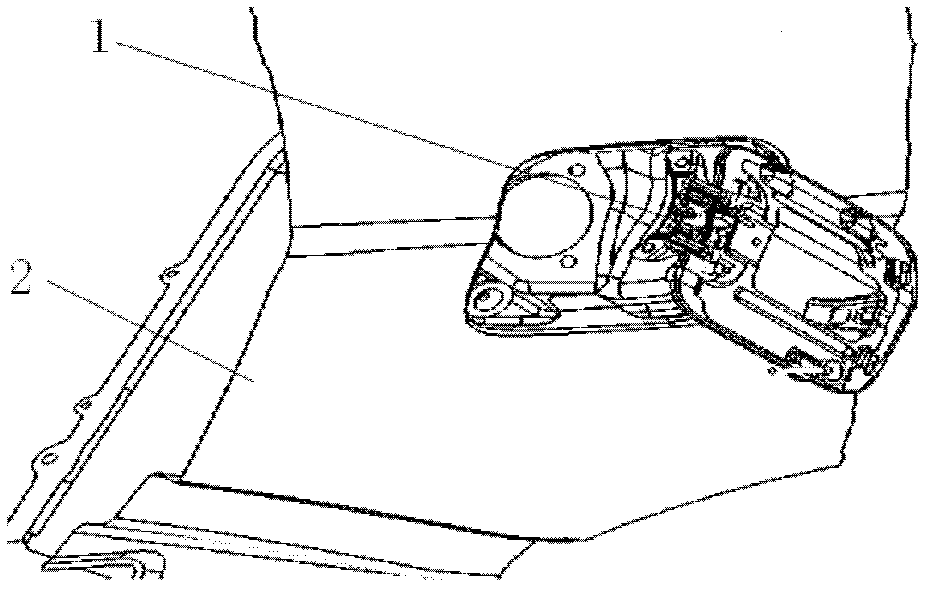

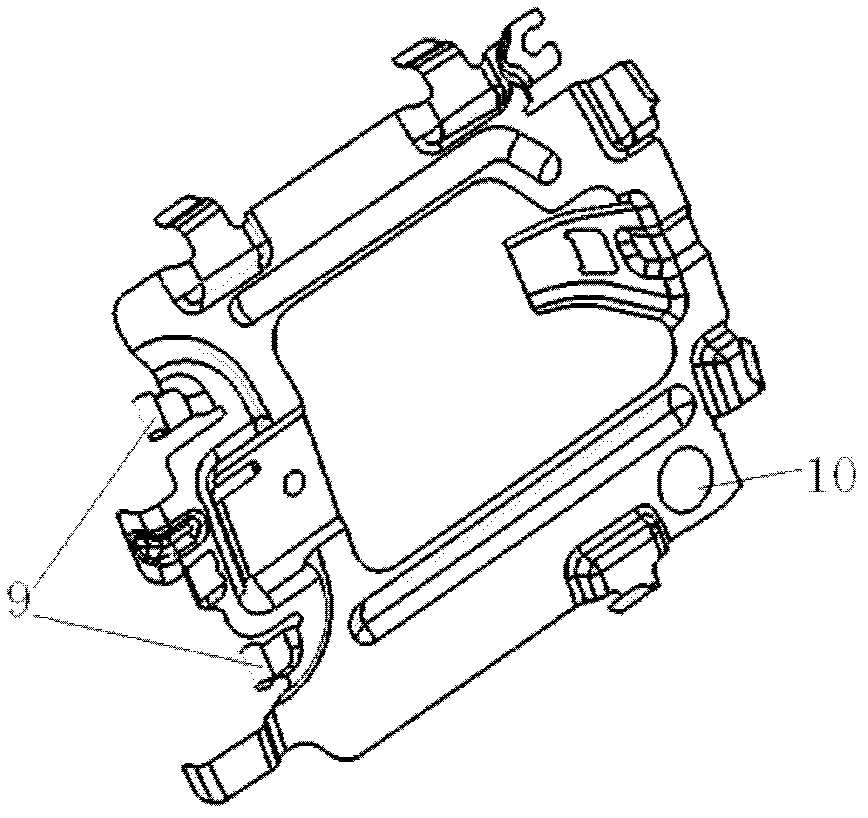

[0021] figure 1 Shown is a schematic structural diagram of the connection between the fuel filler cap assembly 1 and the outer panel of the body side wall 2 , and the fuel filler cap assembly 1 is installed on the body side wall 2 . figure 2 Shown is a schematic diagram of the overall structure of the fuel filler cap assembly 1. The fuel filler cap assembly 1 includes a fuel filler box 3, a hinge seat 4, a fuel filler outer cover, a positioning pin 7, and a positioning pin seat 8. The fuel filler box 3 is tightly bonded by glue. Connected to the fuel filler of the automobile side wall outer panel, the fuel filler outer cover includes an outer plate 6 and an inner plate 5, and the inner plate 5 of the fuel filler outer cover and the fuel filler box 3 are hingedly connected by a hinge. Such as image 3 and Figure 4 As shown, the hinge base 4 and the fuel filler box 3 are connected by bolts, the hinge base 4 and the inner plate 5 are connected together by a pin 9, the inner p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com