An anti-vibration transformer

A transformer and horizontal technology, applied in the field of transformers, can solve problems such as poor anti-vibration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

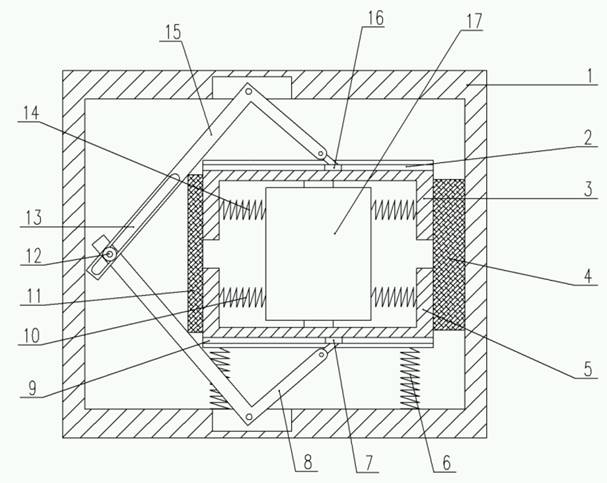

[0020] like figure 1 As shown, an anti-vibration transformer provided by the present invention includes a casing 1, a transformer body 17 is arranged in the inner cavity of the casing 1, a top plate 3 is arranged at the upper end of the transformer body 17, and a lower end of the transformer body 17 is arranged There is a base plate 5.

[0021] Wherein, the top plate 3 includes a first fixed horizontal plate, the upper surface of the first fixed horizontal plate is provided with a first horizontal T-shaped groove 2, and the first horizontal T-shaped groove 2 is horizontally slidably connected with a first horizontal Slider 16. The lower surface of the first fixed horizontal plate is vertically provided with four first fixed vertical plates, the four first fixed vertical plates are respectively arranged around the transformer body 17, and the four first fixed vertical plates are connected with the transformer body 17. A first elastic element 14 is disposed between the transfo...

Embodiment 2

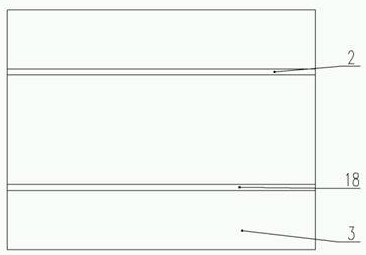

[0026] like figure 2 As shown, the difference between the second embodiment and the first embodiment is that, on the basis of the first embodiment, the second embodiment is also provided with a third horizontal T parallel to the first horizontal T-shaped groove 2 on the top plate 3 A groove 18 is provided, and a third slider is horizontally slidably connected in the third horizontal T-slot 18; a fourth horizontal T-slot parallel to the second horizontal T-slot 9 is also provided on the bottom plate 5, A fourth sliding block is horizontally slidably connected in the fourth horizontal T-shaped groove, a second anti-vibration component is connected between the third sliding block and the fourth sliding block, and the second anti-vibration component is connected to the first anti-vibration component. The structure of the anti-vibration assembly is the same, and the second anti-vibration assembly and the first anti-vibration assembly are symmetrically arranged on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com