Method for producing saline-alkali soil improving agent by utilizing dewatered sludge of domestic sewage plant

A technology for saline-alkali soil and dewatered sludge, which is applied in soil conditioning materials, applications, organic fertilizers, etc., and can solve the problems of alkali corrosiveness, poor site conditions, and low permeability coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

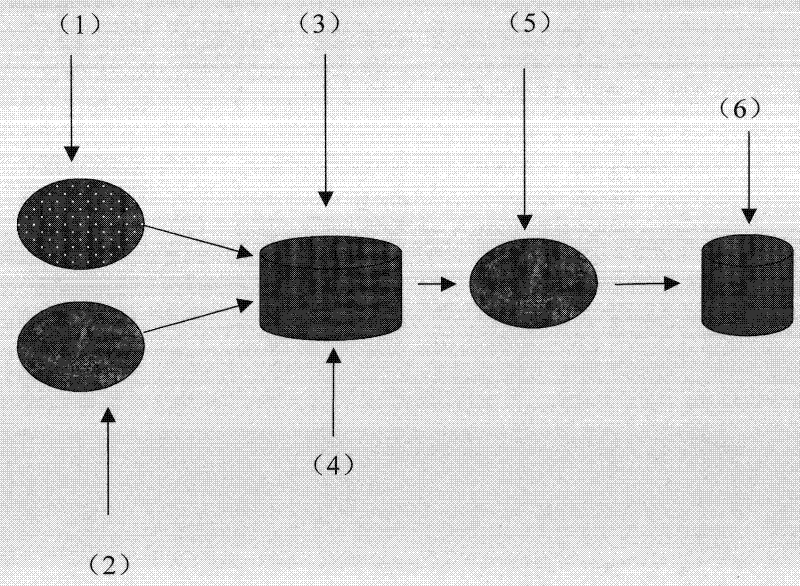

Image

Examples

Embodiment Construction

[0006] 1. Mix 100 parts of dewatered sludge, 15-25 parts of cottonseed hull residue, 5-10 parts of molasses, 25-35 parts of xylitol residue, and 20-25 parts of furfural residue. The percentage of salt bacteria is 100:0.5-1, fully stir evenly.

[0007] 2. Ferment the step 1 for 3 days, the temperature is about 70-80 ℃, high temperature fermentation, turn over the pile and ferment for 3 days, and all of them are fully decomposed.

[0008] 3. Add 12-18 parts of sulfur powder (120 mesh), 5-10 parts of lanthanide oxide, and CaCO to the material fermented in step 2. 3 4-7. FeSO 4 2-6. Fully mix and stir evenly, and the saline-alkali soil improver is prepared after the number of microorganisms and moisture are qualified.

[0009] 4. Properly change the proportions of the above ingredients according to the change of saline-alkali content in saline-alkali land, so as to adapt to the improvement of different saline-alkali lands.

[0010] This saline-alkali soil improver is made from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com