Process for manufacturing organic electroluminescent element, organic electroluminescent element, organic EL display, and organic EL lighting

A technology of electroluminescent element and manufacturing method, which is applied to the manufacturing of electroluminescent light sources, electrical components, semiconductor/solid-state devices, etc., to achieve the effects of high brightness and long driving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0373] Next, although an Example demonstrates this invention more concretely, this invention is not limited to description of a following Example unless the summary is exceeded.

[0374] [Measurement of Relative Permittivity]

reference example 1

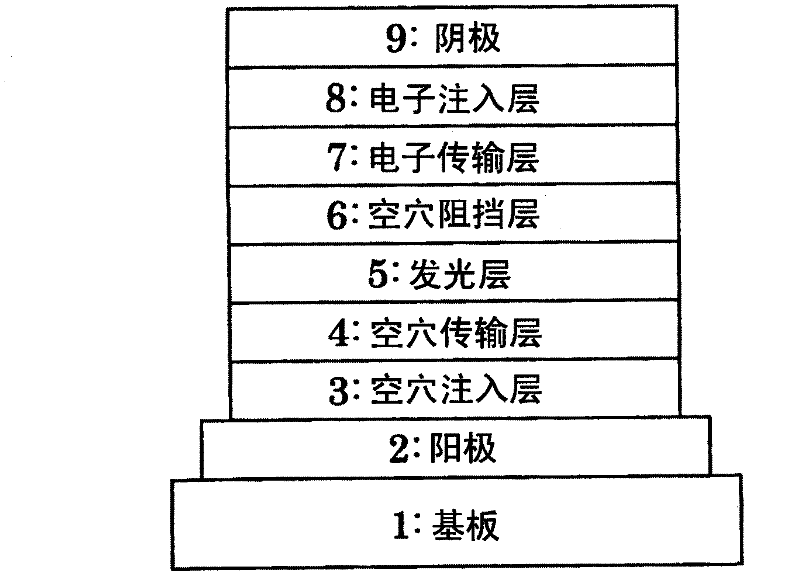

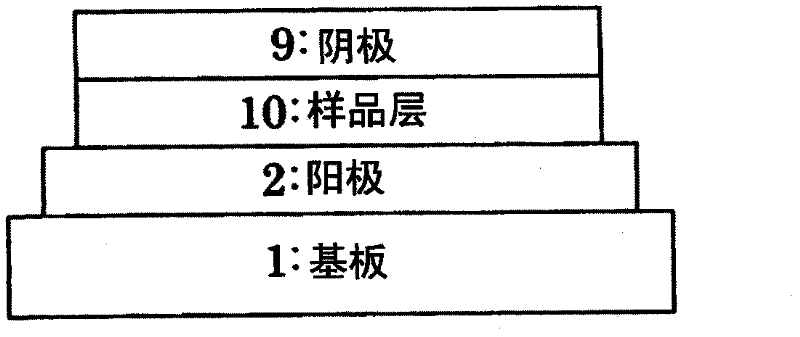

[0376] make figure 2 Device for measuring relative permittivity with the structure shown. A product obtained by depositing an indium tin oxide (ITO) transparent conductive film (manufactured by Sanyo Vacuum Industries Co., Ltd., manufactured by Sanyo Vacuum Industries Co., Ltd., by sputtering into film product) was patterned into stripes with a width of 2 mm to form electrodes 2 . The patterned ITO substrate was washed in the order of ultrasonic cleaning with aqueous surfactant solution, water washing with ultrapure water, ultrasonic cleaning with ultrapure water, and water washing with ultrapure water, and then dried with compressed air. Finally, ultraviolet ozone washing is carried out. This ITO functions as an electrode.

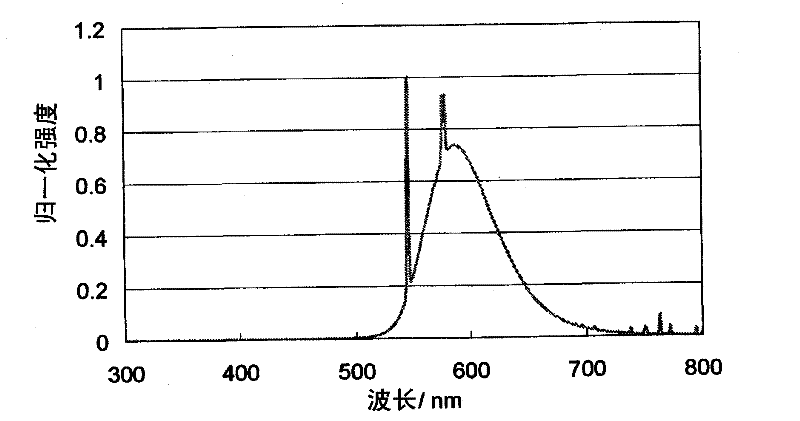

[0377] Preparation contains the compound (C1) shown in following structural formula, aromatic amine compound (C2) and the coating liquid of compound (D1), in image 3 In the environment of the spectrum shown, a film was formed on an ITO patterned sub...

reference example 2

[0397] In Reference Example 1, except for having Figure 4 An element for relative permittivity measurement was produced in the same manner as in Reference Example 1 except that the film-forming sample layer 10 was formed under the environment of the spectrum shown.

[0398] The obtained values of relative permittivity are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com