Item taking-placing device

A technology for picking and placing devices and articles, which is applied in the directions of object separation, conveyor objects, transportation and packaging, etc., can solve the problems of slow picking and placing bags, taking a long time, and low work efficiency, and achieves high work efficiency. Concise, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

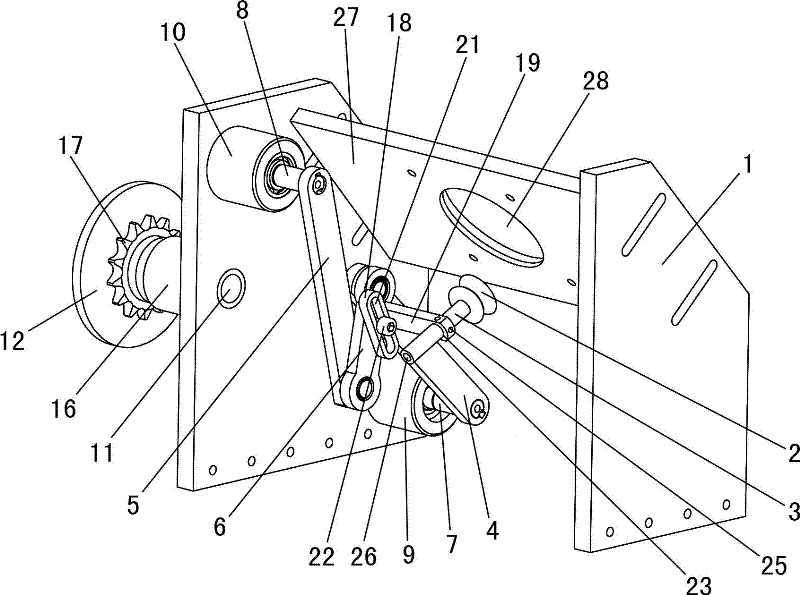

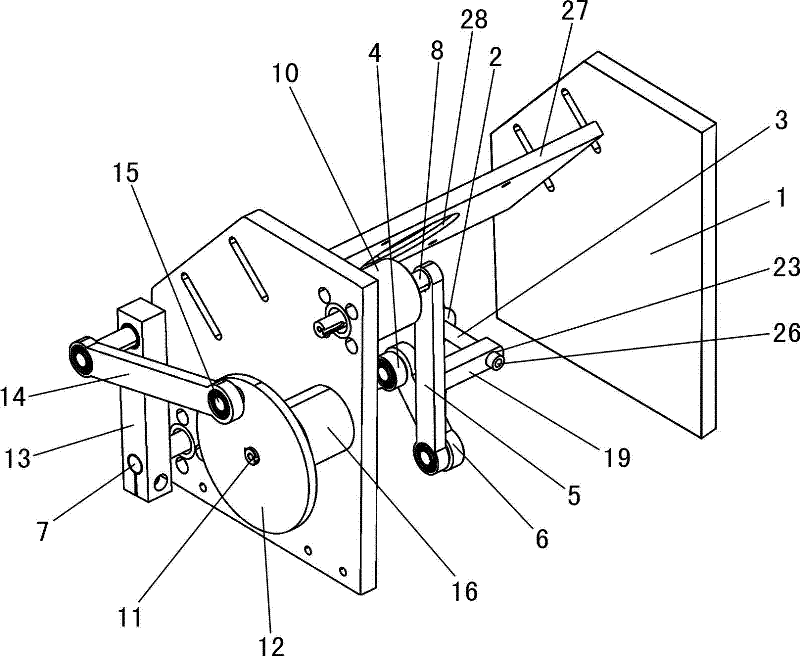

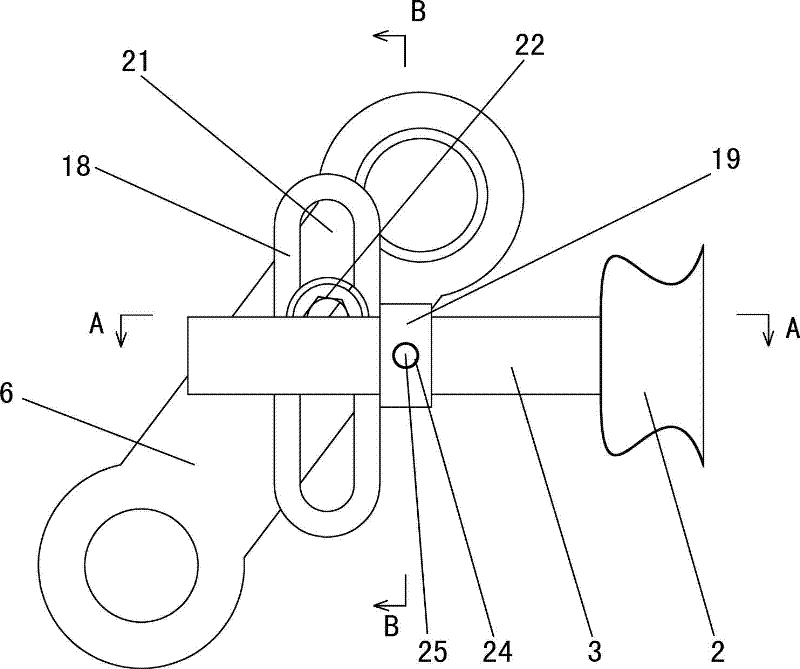

[0022] Such as figure 1 and figure 2 As shown, this article pick-and-place device includes a frame 1, a suction cup 2, a suction cup seat 3 and a suction cup position changing mechanism.

[0023] The suction cup position changing mechanism includes a first rocker 4, a second rocker 5, a first connecting rod 6, a first rotating shaft 7, a second rotating shaft 8, and a swing driving mechanism capable of driving the first rocking rod 4 to swing back and forth; The rotating shaft 7 is installed on the frame 1 through the bearing seat 9, and the first end of the first rocker 4 is fixedly connected with the first rotating shaft 7, so that the first end of the first rocking rod 4 is rotatably mounted on the frame 1; The second rotating shaft 8 is installed on the frame 1 through the bearing seat 10, and the first end of the second rocker 5 is fixedly connected with the second rotating shaft 8, thereby realizing that the first end of the second rocking rod 5 is rotatably installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com