Folding device and method for folding-gluing machine

A technology of a folding device and a gluing machine, which is used in packaging, transportation and packaging, container manufacturing machinery, etc., can solve problems such as unsatisfactory, and achieve the effect of eliminating noise problems, quiet working environment, and good production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

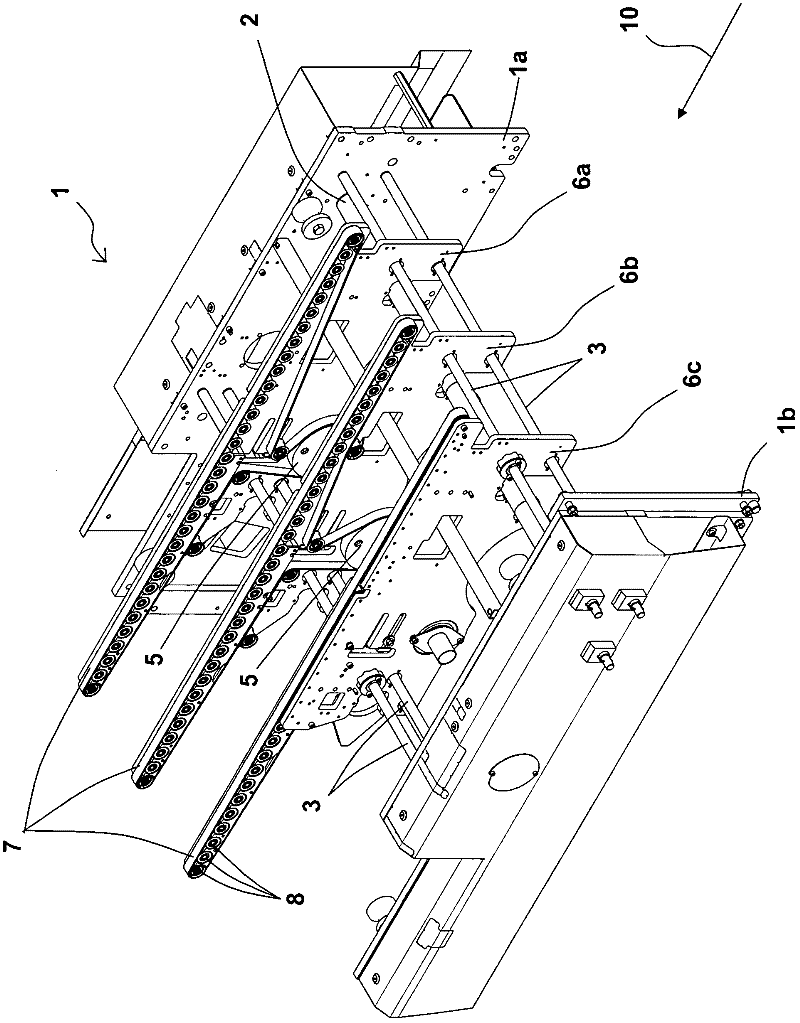

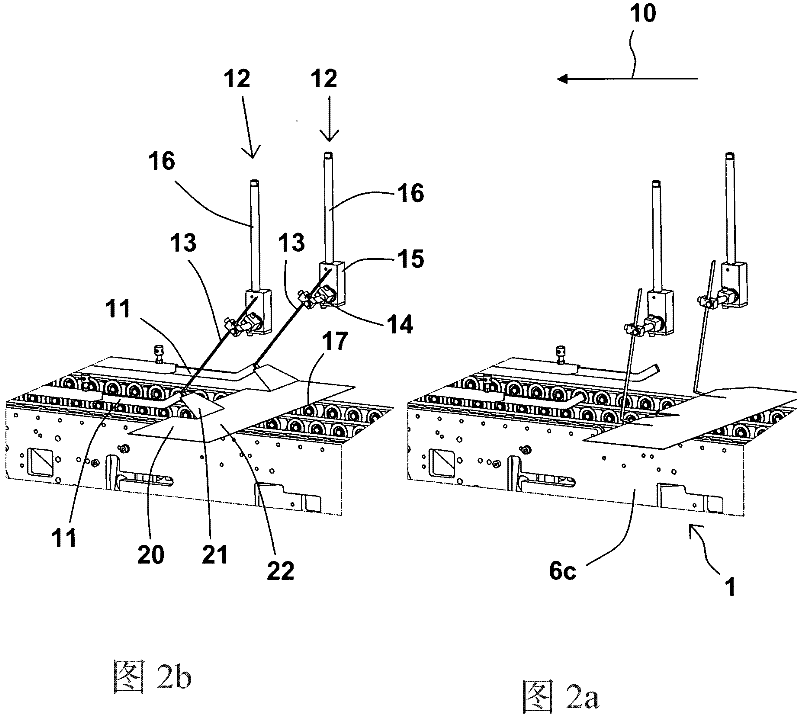

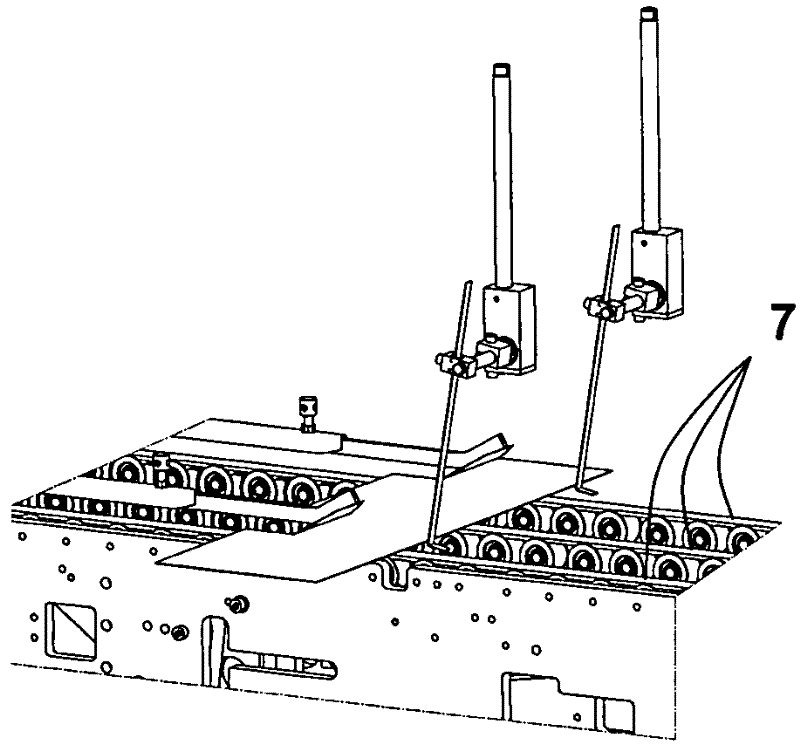

[0038] figure 1 A prior art conveyor 1 is shown. Arrow 10 indicates the direction of travel of the blanks, also referred to as the transport path. Such a conveyor generally comprises two parallel spaced apart longitudinal frames 1a, 1b. Each frame has two major surfaces; an inner surface and an outer surface, with the inner surface of one frame facing the inner surface of the other frame. In this example, the frame 1a is on the other side of the operator and the frame 1b is on the operator's side. The parallel cylindrical displacement slide block 2 (only one slide block is shown in the figure), the paired parallel screw rods 3 and the drive shaft (not shown) that are rotatably installed between the two frames are arranged laterally on the two frames 1a, between 1b. Each end of the displacement slide 2 is constructed in the frame 1a, 1b to support three parallel longitudinal beams 6a, 6b, 6c mounted side by side, each supporting an endless conveyor belt 7 resting on the On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com