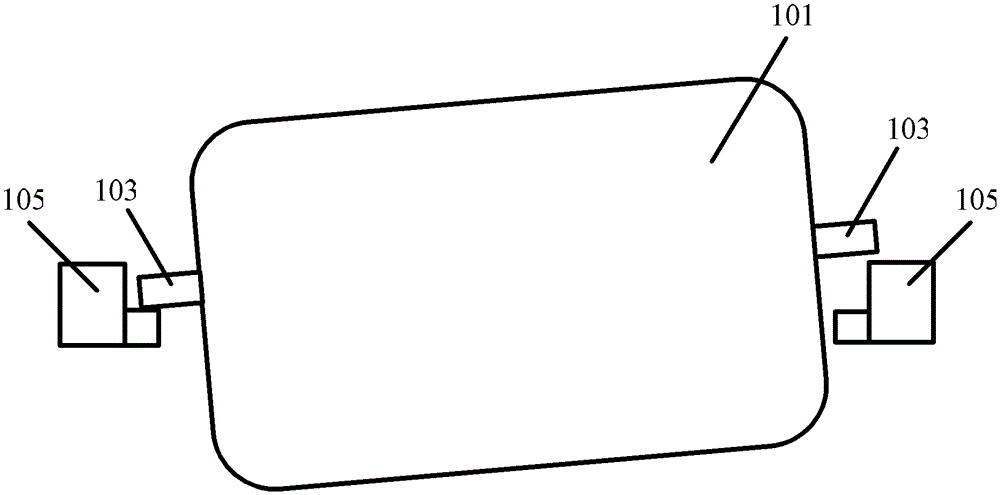

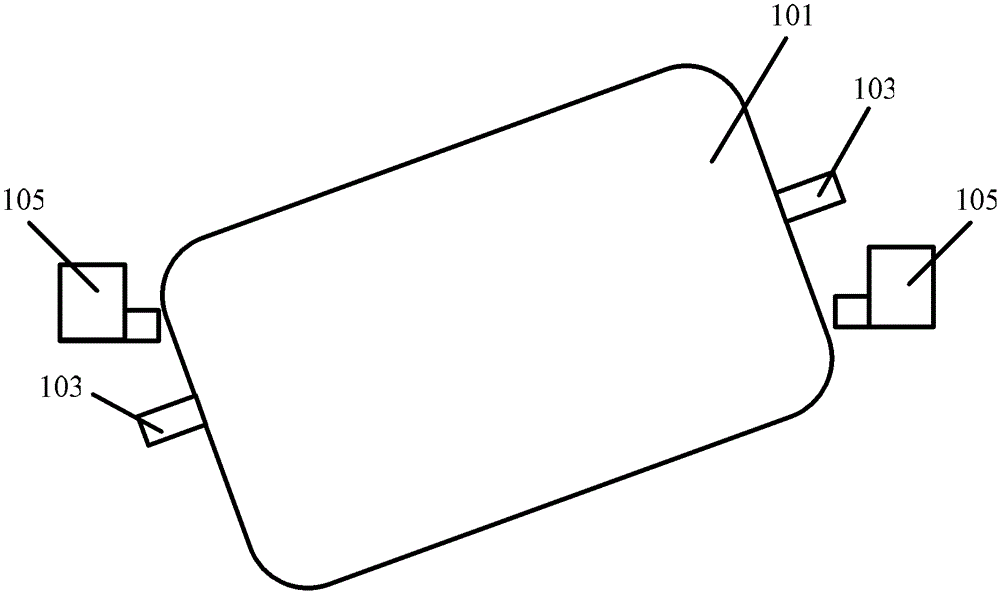

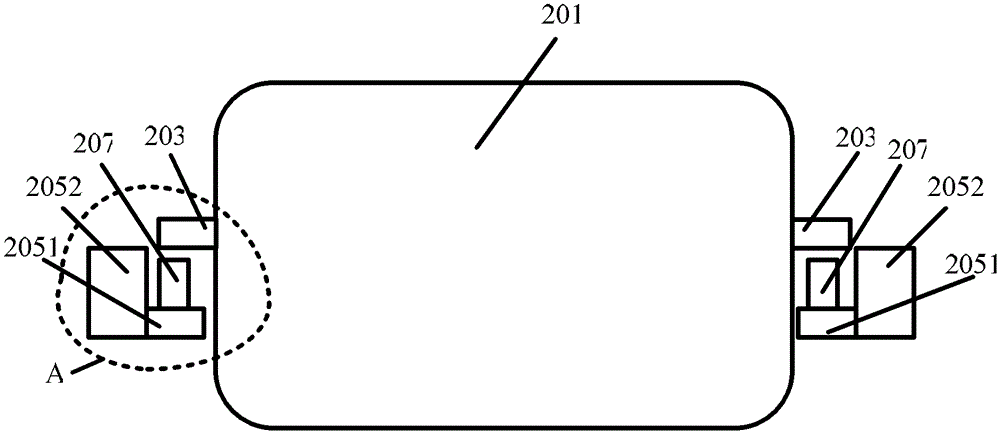

Wafer cassette transfer system and method

A technology of conveying system and wafer box, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of scrap wafers, low reliability of wafer boxes, etc., and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] As mentioned in the background, in the prior art wafer box transfer system, the wafer box is easy to slip, the wafer is broken and scrapped, and the reliability of wafer box transfer is low.

[0035] After research, the inventors of the embodiments of the present invention found that, in the prior art cassette transfer system, light-sensitive sensors are mainly used, and the light-sensitive sensors include a transmitting unit and a receiving unit. In the prior art, the transmitting unit of the photosensitive sensor is installed on the first side of the clamping part, and the receiving unit of the photosensitive sensor is installed on the second side of the clamping part, and the second side is connected to the clamping part. The first sides are opposite. When using the clamping part to transport the wafer cassette, when the receiving unit of the photosensitive sensor cannot receive the light signal generated by the transmitting unit, it is considered that the clamping p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com