Garbage anti-blocking device

A garbage and anti-blocking technology, applied in the direction of combustion method, combustion type, grain processing, etc., can solve the problems of arching, complex shape and size, increase the labor intensity of operators, etc., to prevent blockage or arching, and ensure stability. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

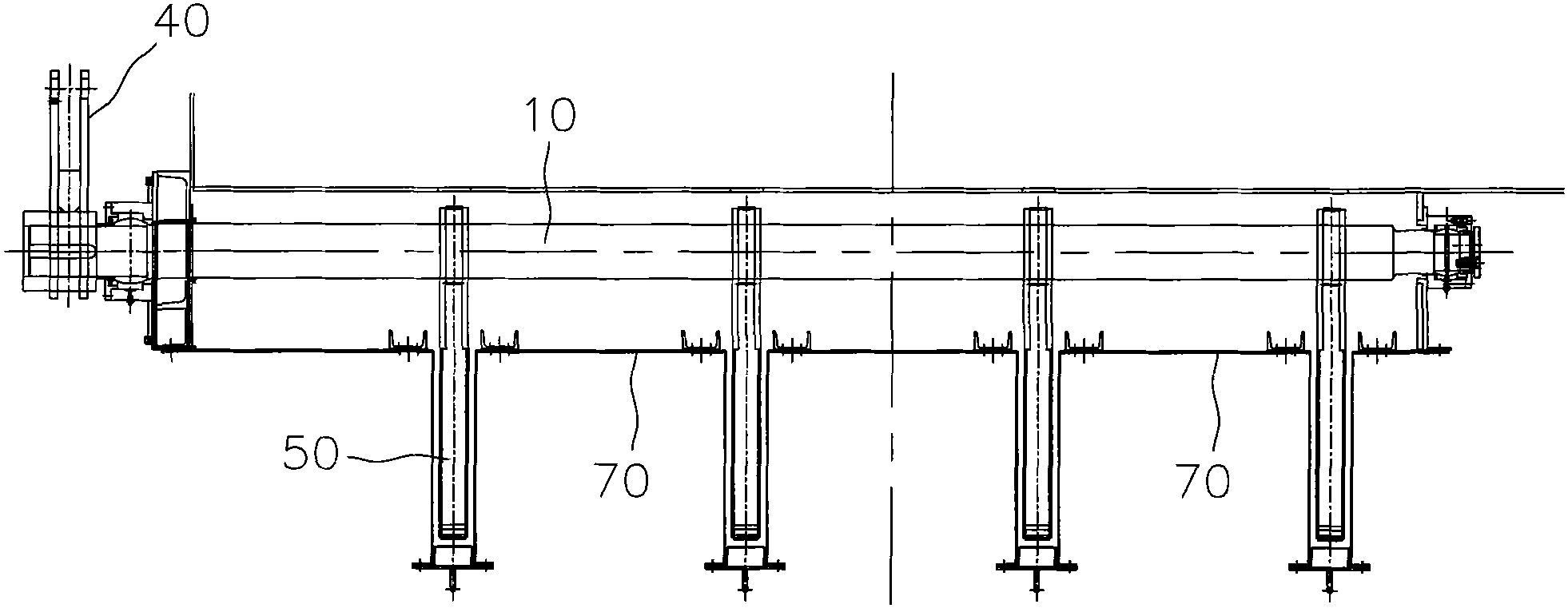

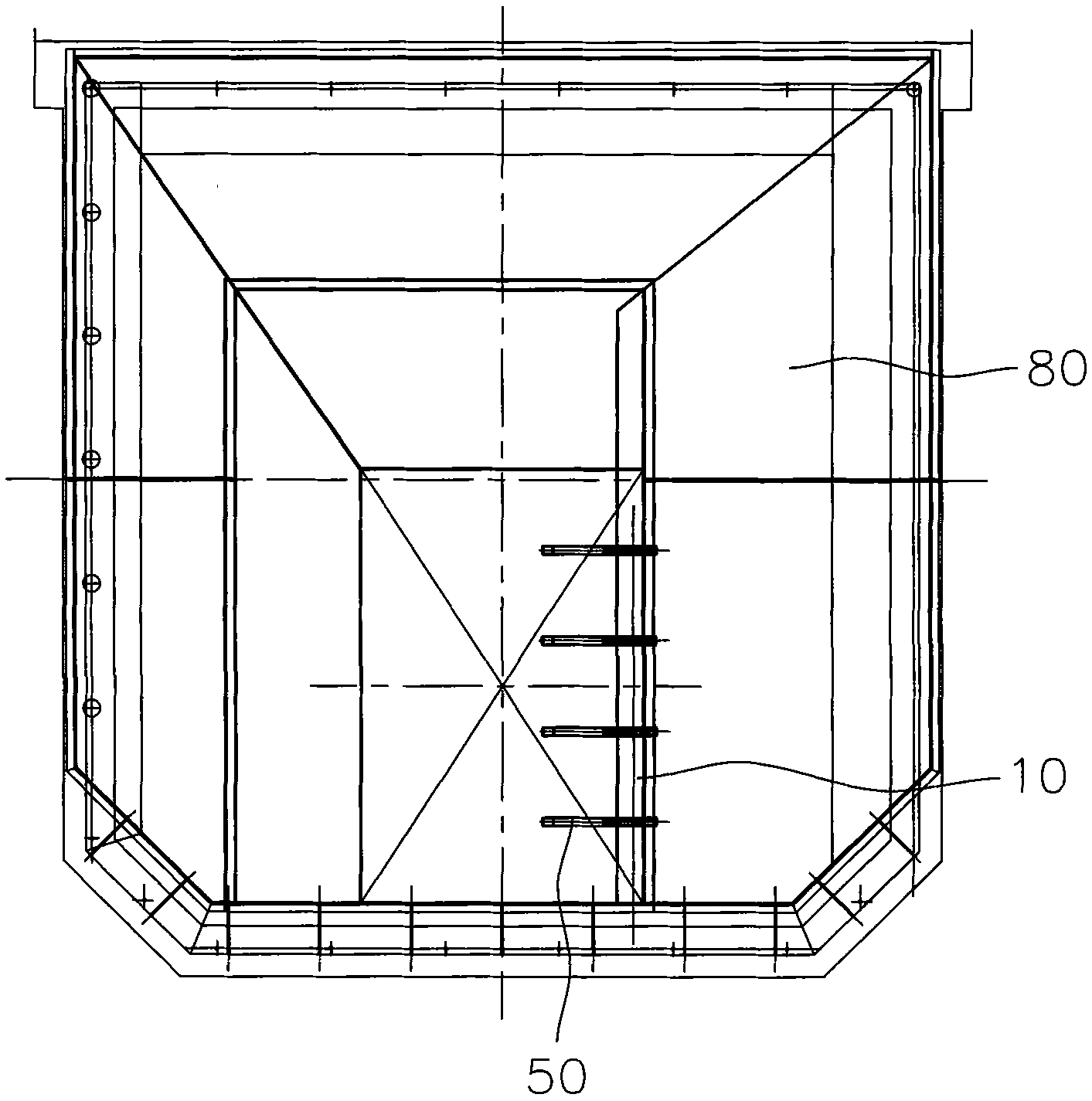

[0015] Such as figure 1 , 6 As shown, a garbage anti-blocking device, the garbage anti-blocking device includes a shaft 10 and a power device for driving the shaft 10 to rotate, the shaft body of the shaft 10 is provided with crushing parts, and the driving shaft 10 of the power device makes the crushing parts in the state of rotating loose garbage Or stop and stop.

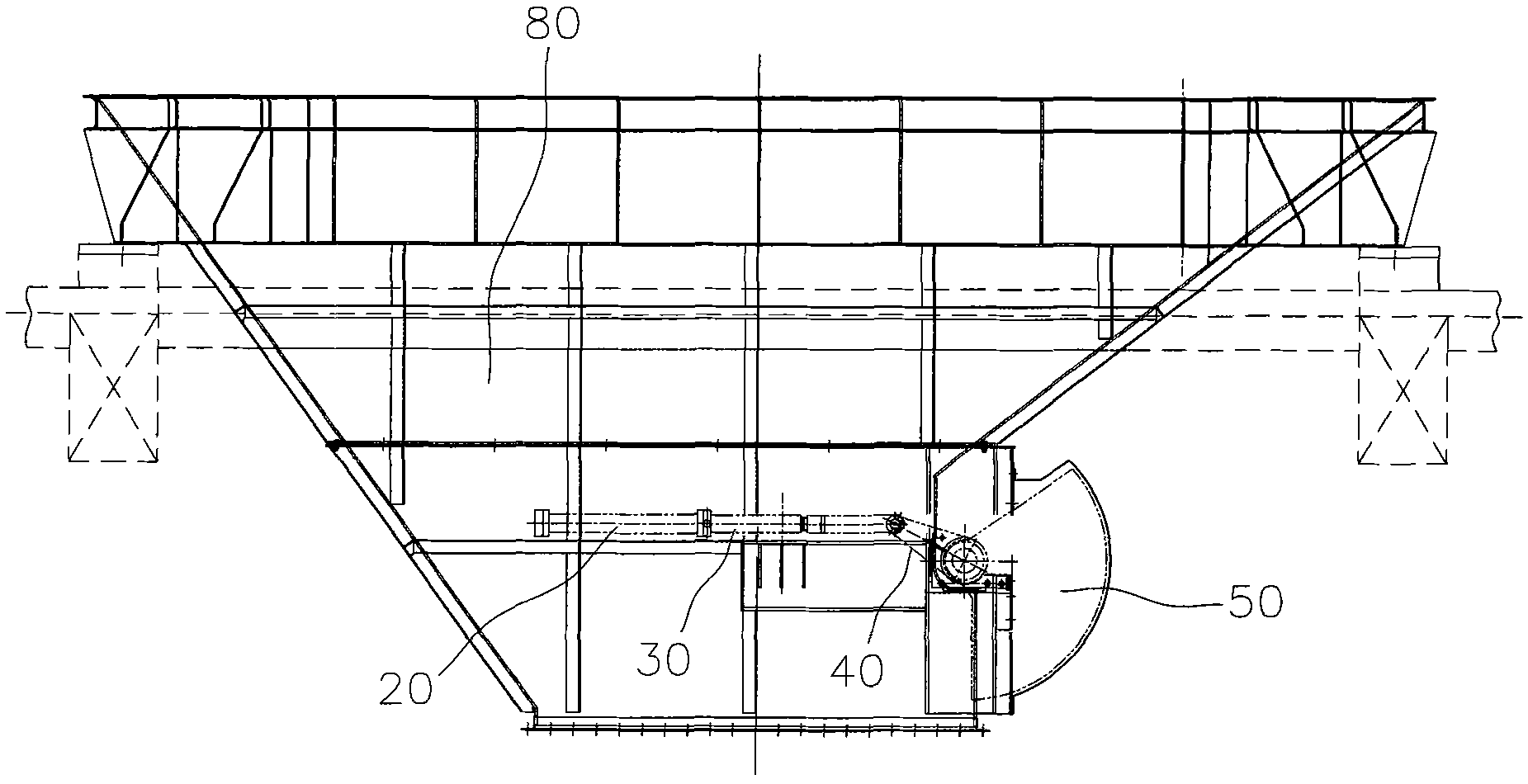

[0016] An electric motor can be selected as the power unit for the rotation of the drive shaft 10 . For garbage disposal, because the garbage is not always in the state of being blocked or arched, and because the various components in the garbage are entangled with each other, sufficient power is needed to loosen the garbage, so it is the preferred solution of the present invention. ,Such as image 3 , 6 As shown, the power device includes a hydraulic cylinder 20 and a piston rod 30 arranged in the hydraulic cylinder 20, the end of the piston rod 30 extending outside the hydraulic cylinder 20 is hinged to one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com