Fast assembling and disassembling device for support carrier

A technology for a support truck and a loading and unloading device, which is applied to pillars/supports, transportation and packaging, underground transportation, etc., can solve problems such as hidden safety hazards, safety accidents, and backward hoisting mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

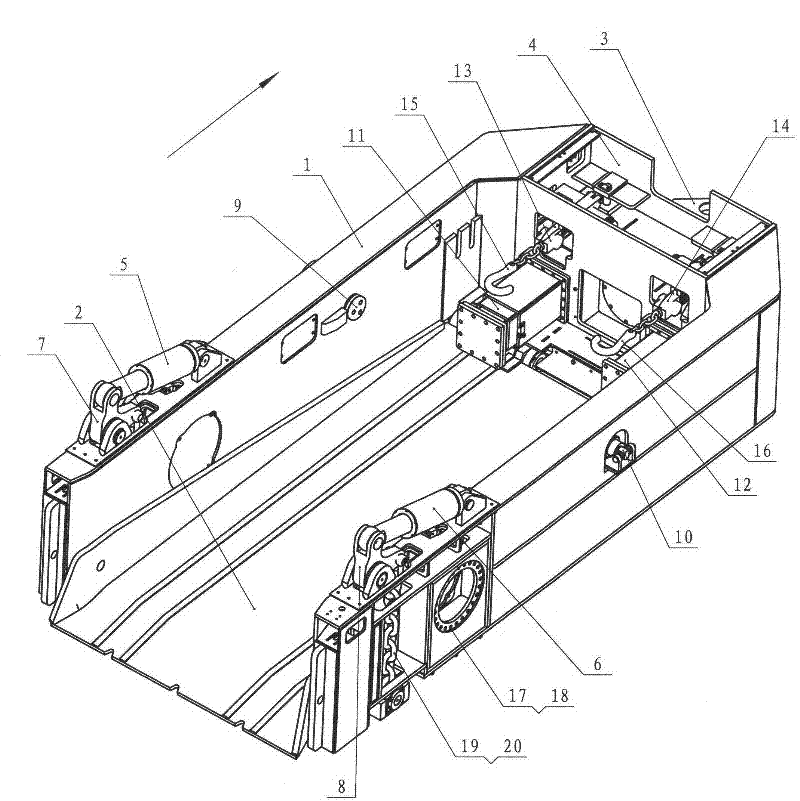

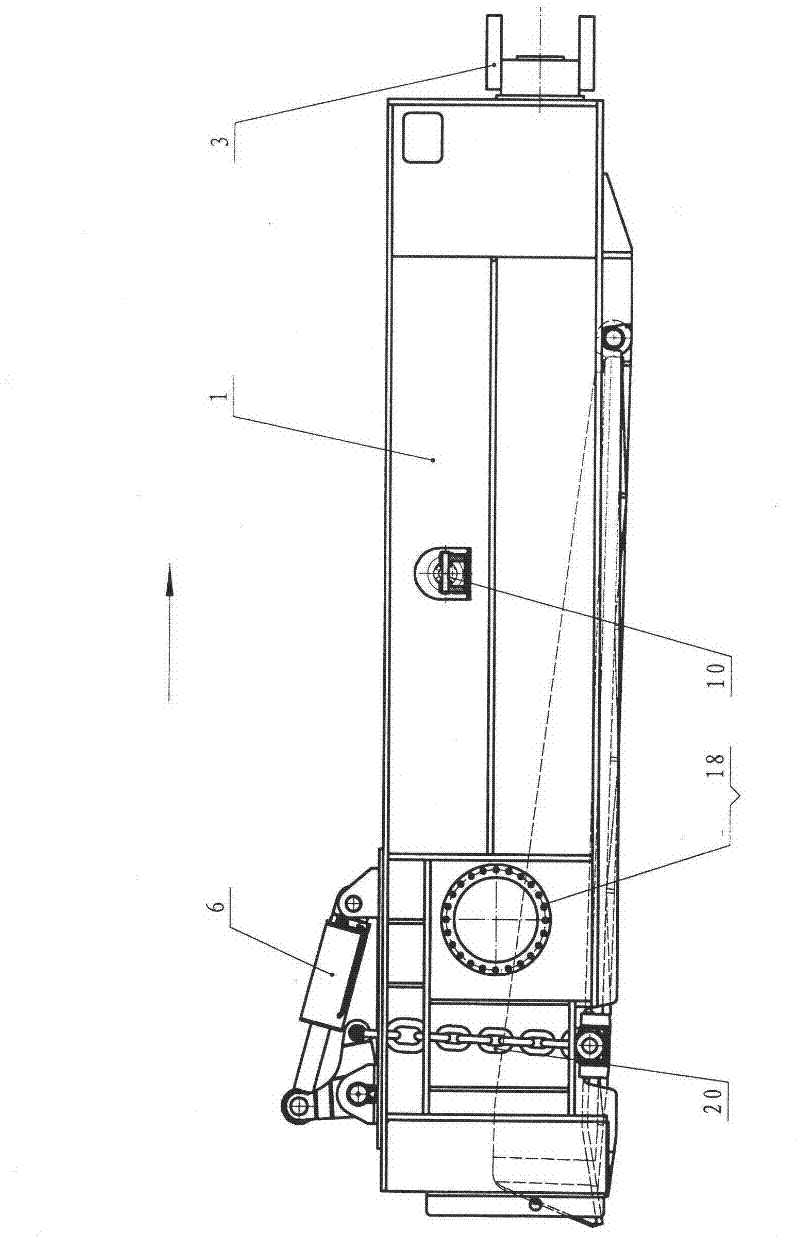

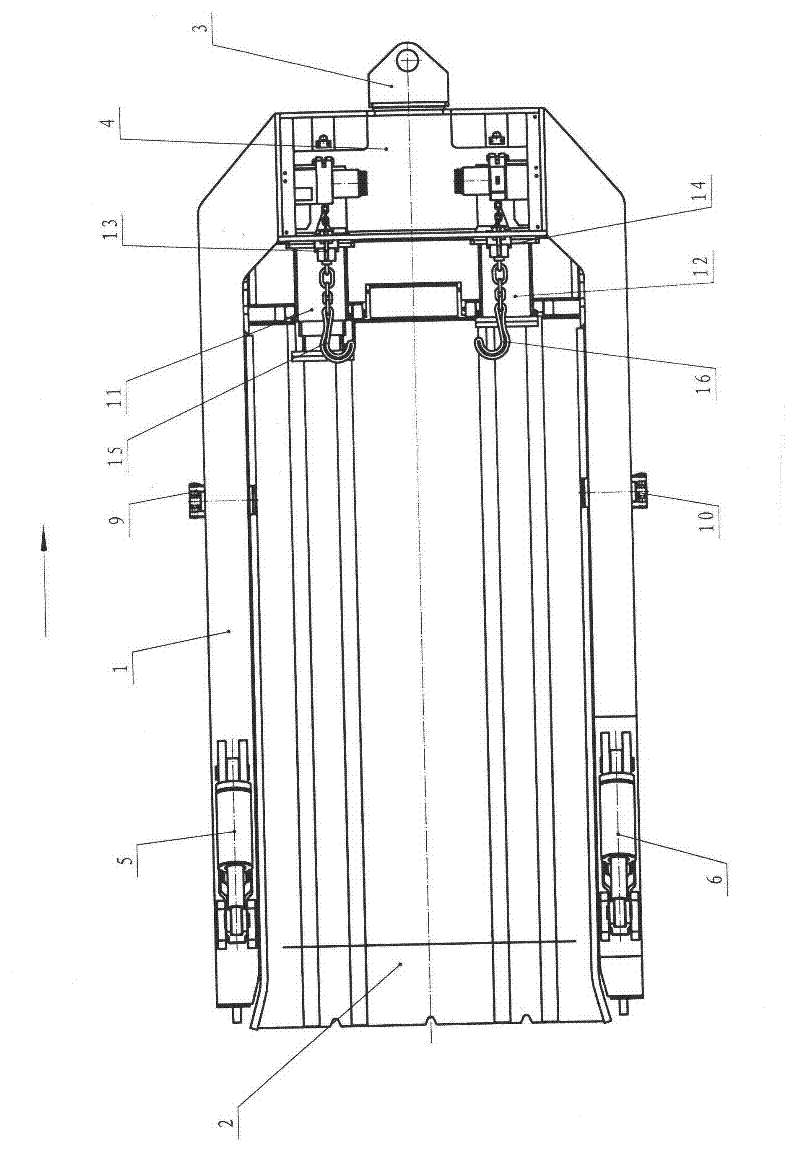

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] figure 1 , 2 , 3, and 4 show the overall structure diagram, the position and connection relationship of each part must be correct, and the installation should be firm.

[0026] The main body of the quick loading and unloading device is a U-shaped frame 1, the inner bottom of the U-shaped frame 1 is a shovel plate 2, the right front part of the U-shaped frame 1 is a winch box 4, and the rear part of the winch box 4 is a hinged frame 3;

[0027] The inside of winch box 4 is provided with first winch 13, second winch 14, and first winch 13 connects first hinge hook 15, and second winch 14 connects second hinge hook 16; There are a first moving mechanism 11 and a second moving mechanism 12;

[0028] A first clamping mechanism 9 and a second clamping mechanism 10 are arranged on the left and right in the middle of both sides of the U-shaped frame 1;

[0029] The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com