Lift system for constructing truss platform on top of tall and large space

The technology of a truss platform and a lifting system is applied to the scaffolding, housing structure support, housing structure support and other directions supported by the building structure, which can solve the problems of difficult construction requirements, slow construction speed, large workload, etc., and achieves fast erection speed. Reduce workload and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

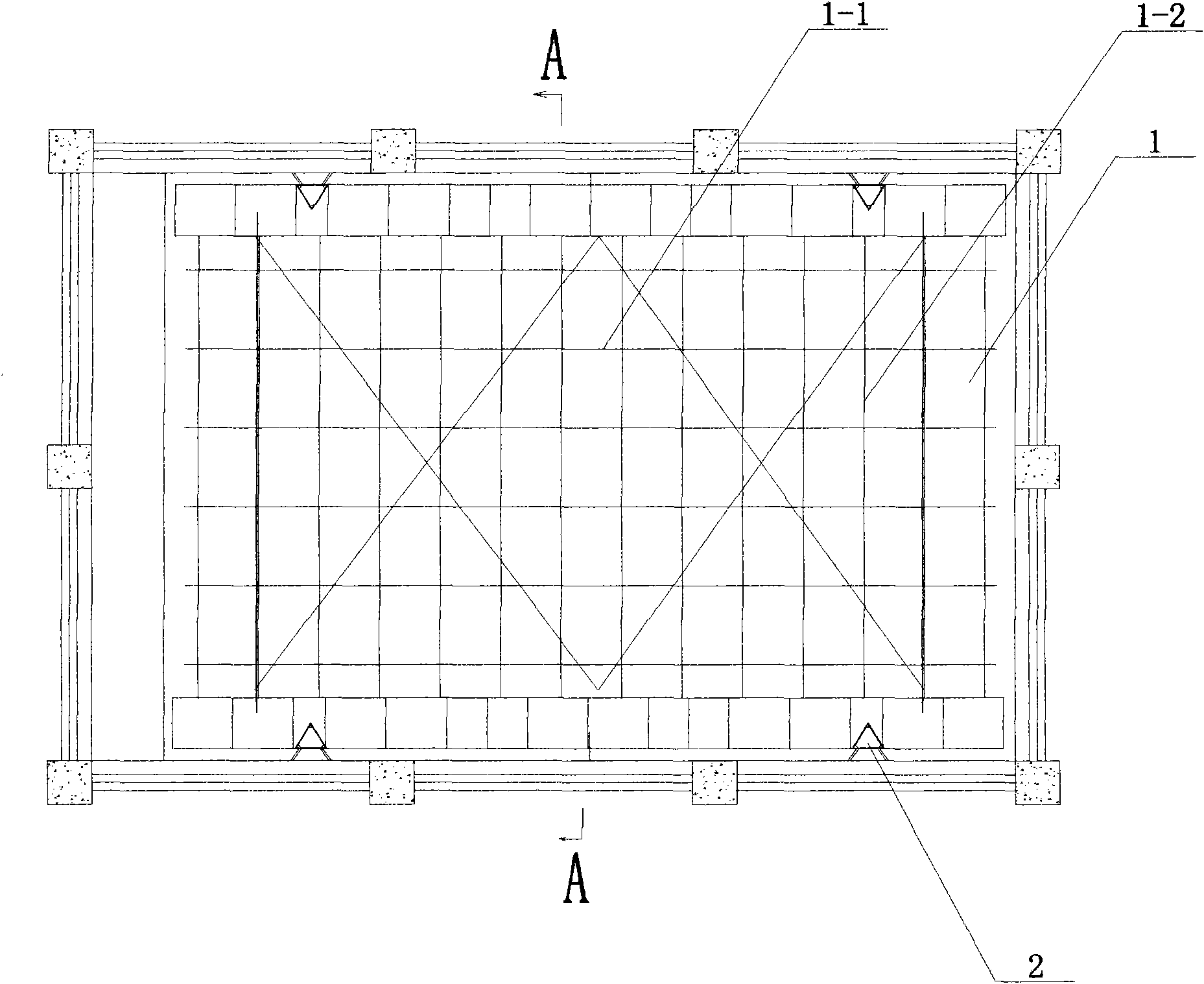

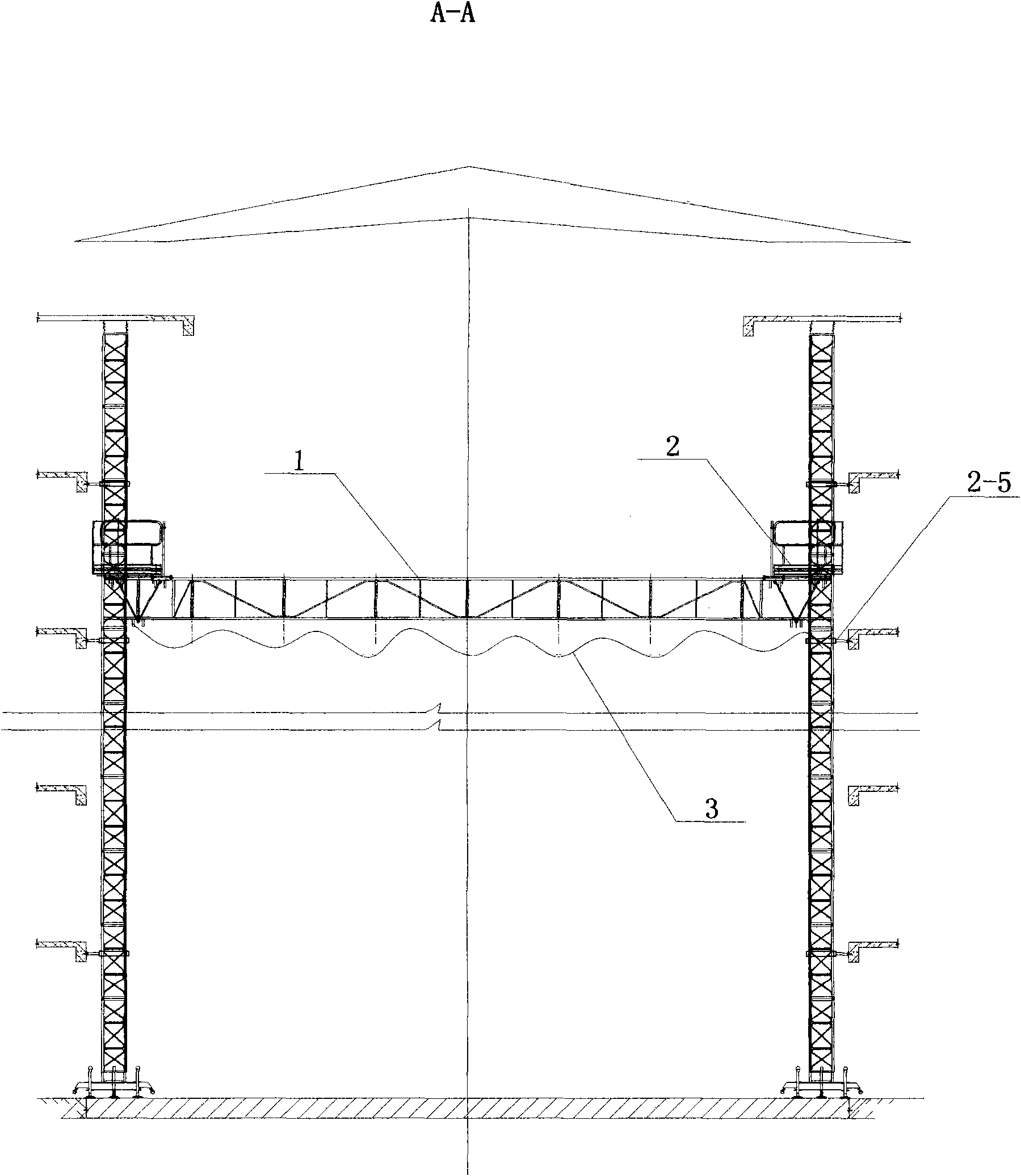

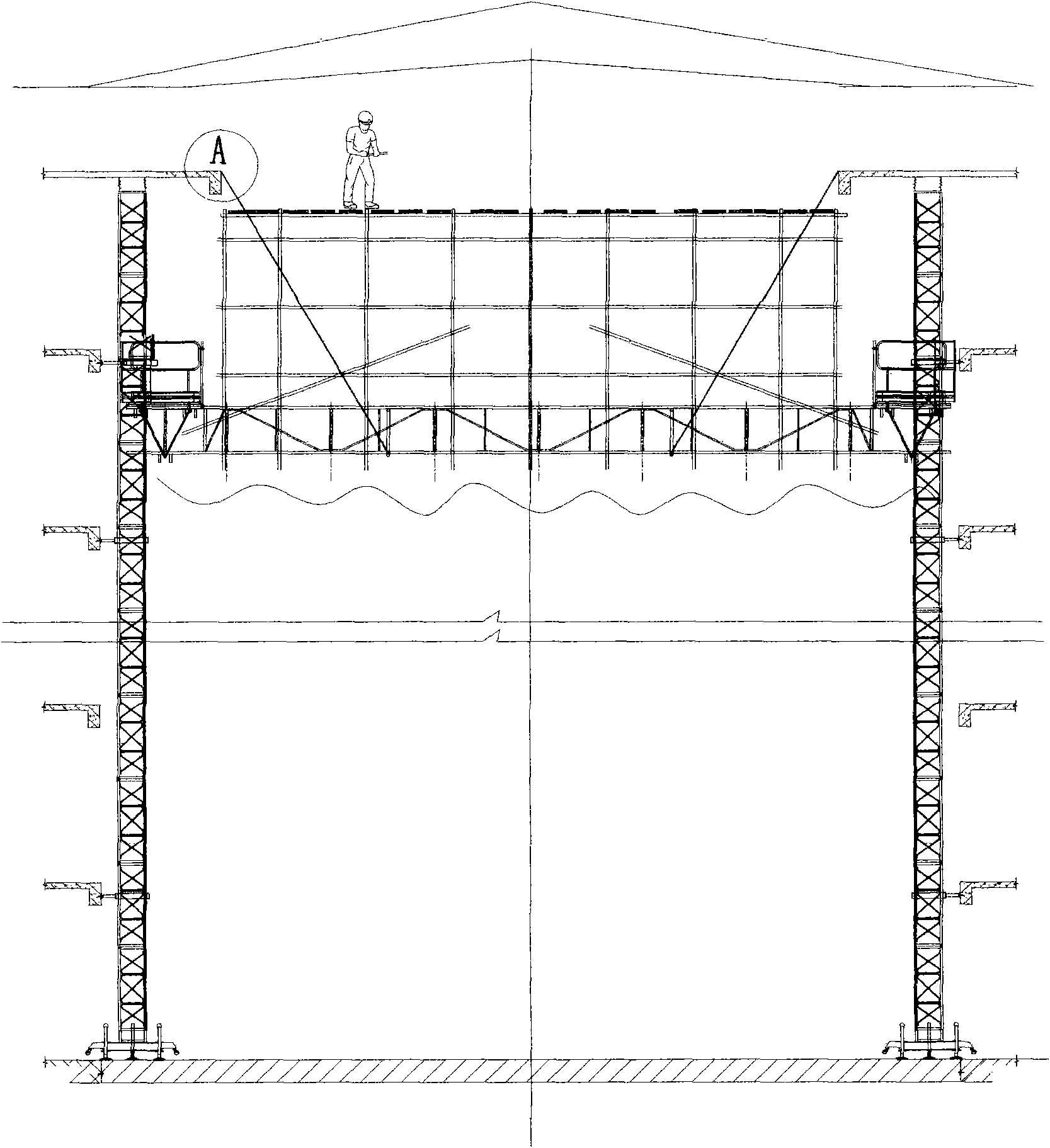

[0037] In this embodiment, the central hall of the building from the fifth floor to the top is a high-altitude patio of 14.9 meters × 21 meters. In addition to the brick decoration of the structural columns on three sides, and the embossed decoration on the other side, it is a decoration difficulty. It is the top lighting shed to be decorated. The height from the fifth floor to the top lighting shed is nearly 70 meters. If you follow the ordinary scaffolding scheme, the required scaffolding is relatively large, about 200 tons, and it takes a long time to set up , can not meet the construction period requirements.

[0038] In this embodiment, a 1-meter-high truss platform is built with φ48 steel pipes on the platform beams of 4 units in the 21-meter-long direction using the electric construction platform that has been erected. After the erection is completed, the φ48 steel pipes are erected by the electric construction platform. The truss platform is gradually lifted to the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com