Quickly synchronized shifting method of gearbox

A gearbox, fast technology, applied in the field of gearbox shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

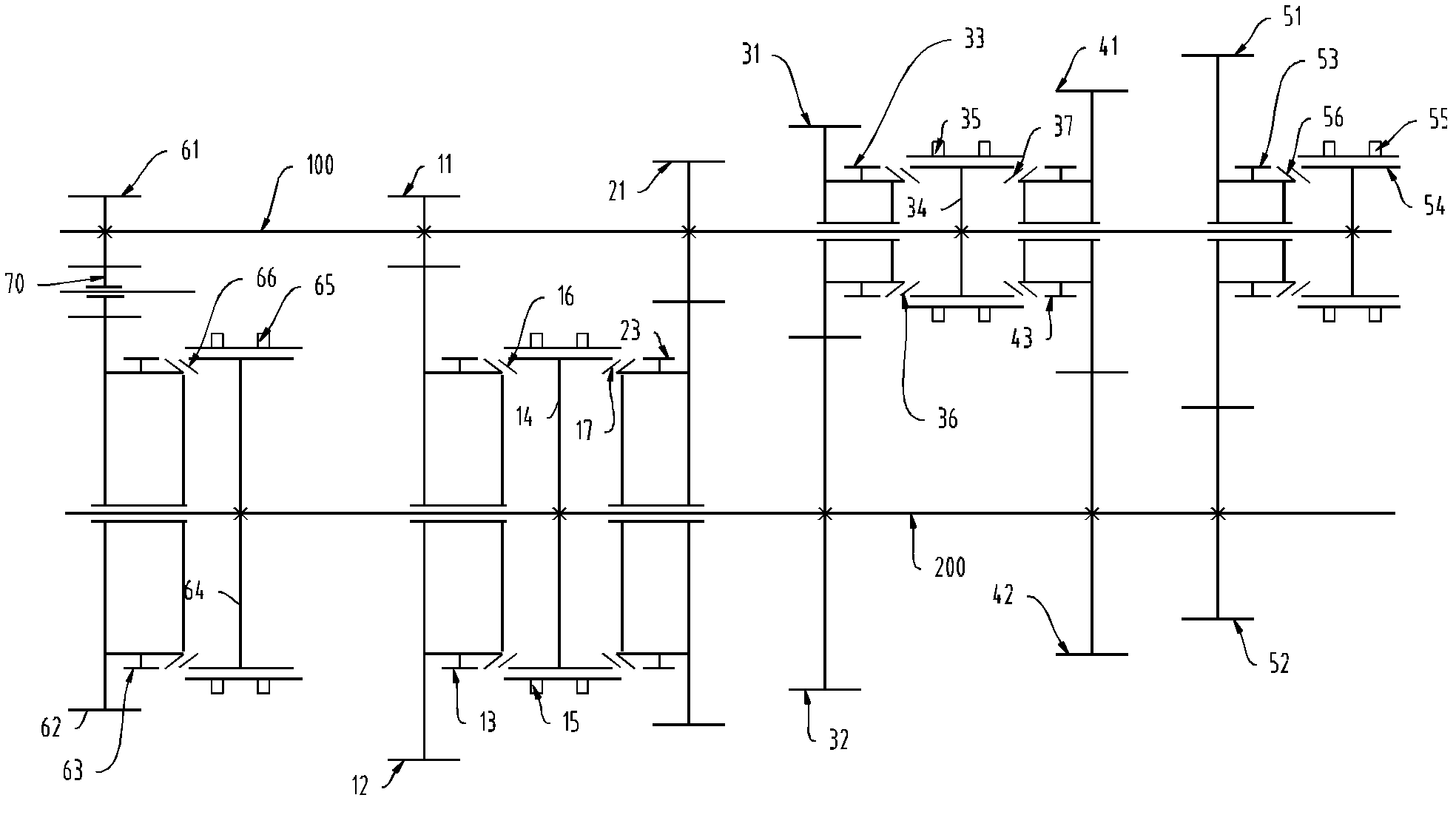

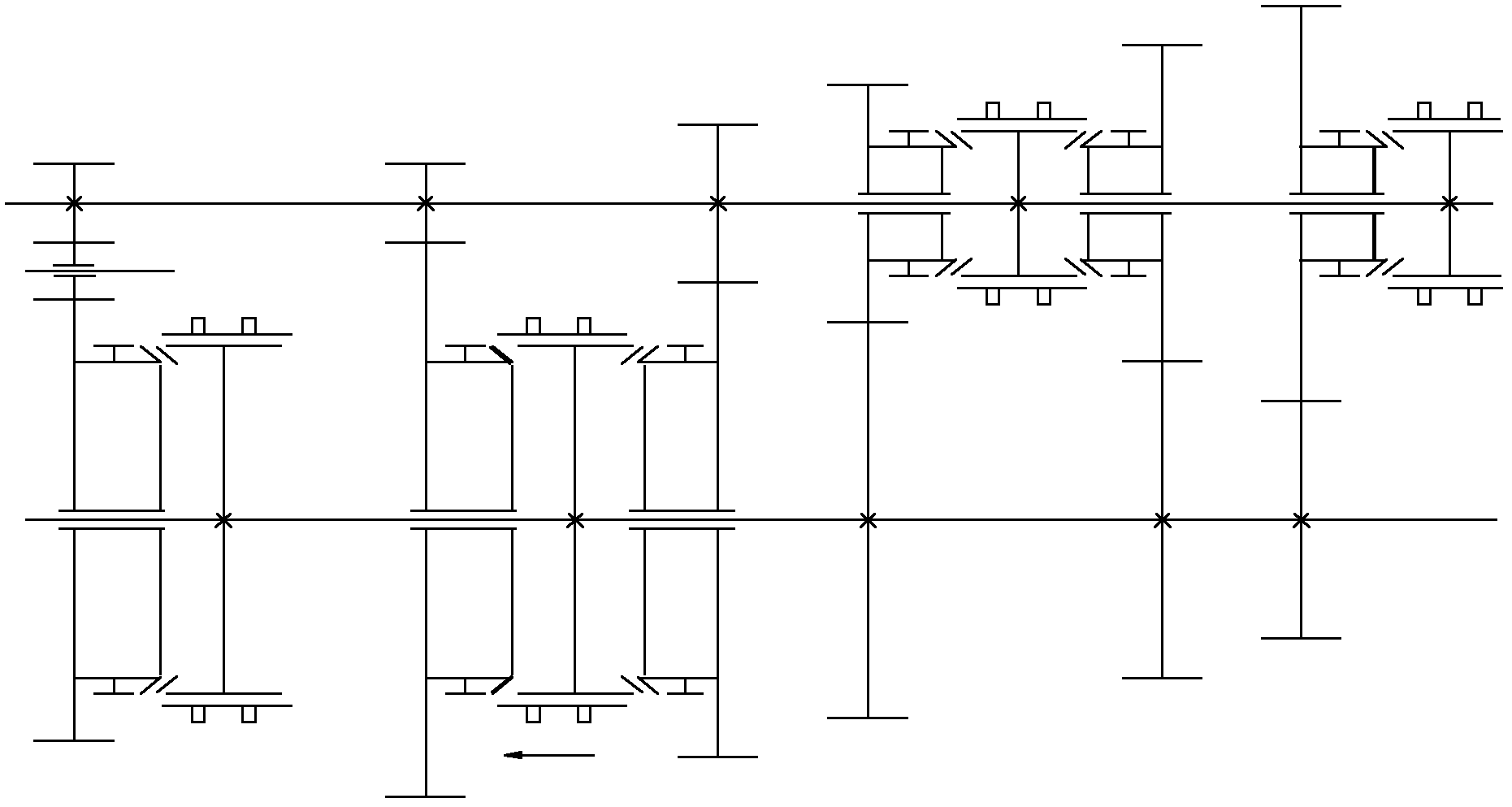

[0039] see Figure 6 , 7 , when the gearbox is idling (neutral), assuming that the rotational speed of the input shaft 100 (and the first gear input gear) is 1000 revolutions, according to the first gear ratio, the rotational speed of the first gear output gear is 200 revolutions, and the output shaft does not rotate. When starting in first gear, the first and second gear rings move to the left under the control of the shifting mechanism, and the first and second gear rings press against the first gear synchronizer, so that the first gear synchronizer (target gear synchronizer) starts the synchronization process. , the speed of the input shaft (and first gear input gear, first gear output gear) gradually decreases. In order to make the input shaft speed decrease faster, we use the third-gear synchronizer (or fourth-gear synchronizer), fifth-gear synchronizer, and reverse-gear synchronizer as participating gear synchronizers, so that the third-gear synchronizer (or fourth-gear...

Embodiment 2

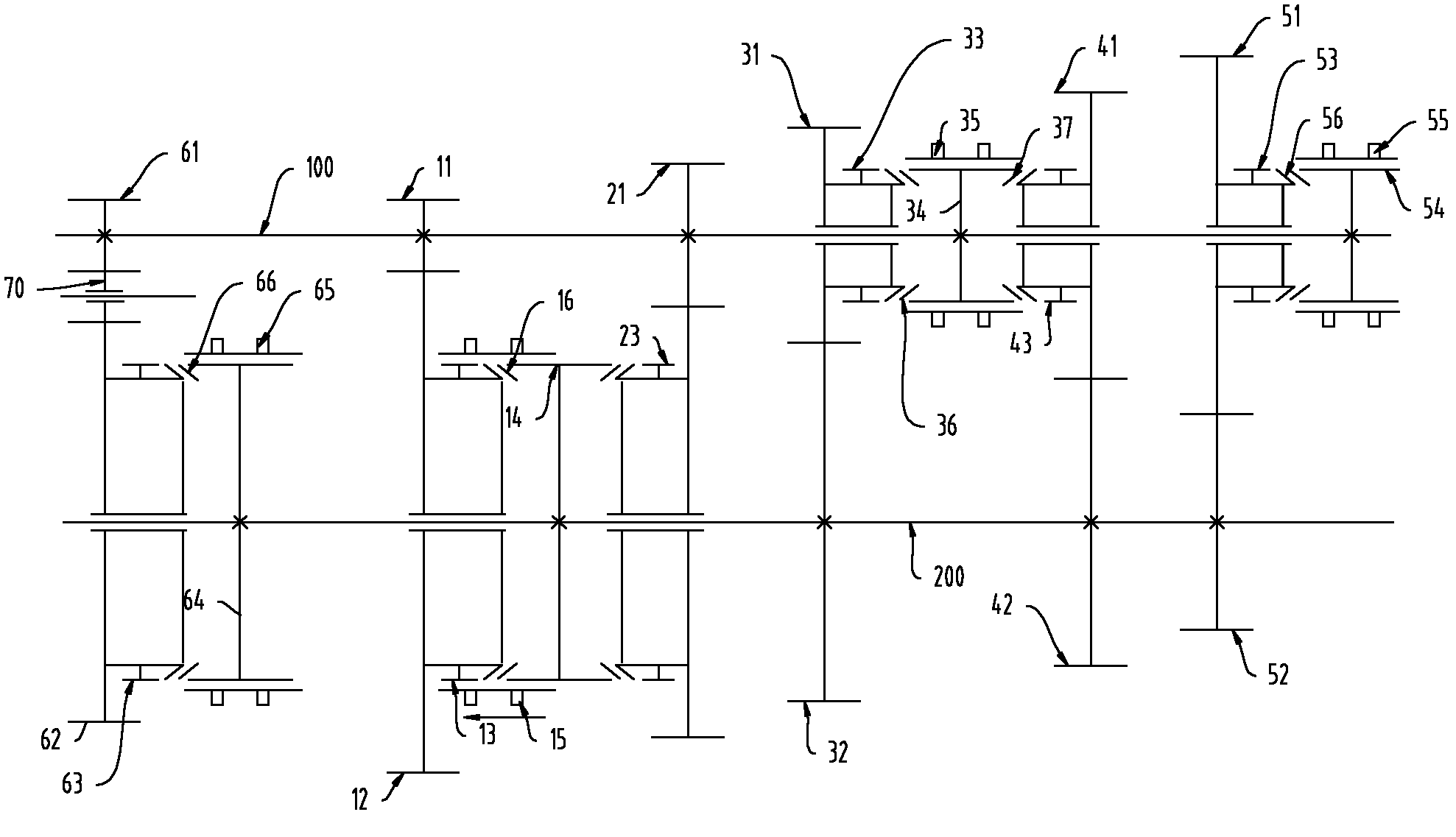

[0045] see Figure 10 , 11 , when the car is moving forward, the gearbox is engaged in the fifth gear, assuming that the rotational speed of the input shaft 100 is 2000 rpm, according to the fifth gear ratio, the rotational speed of the fifth gear output gear and the output shaft is 2000 rpm, the fifth gear ring and The speed of the fifth gear input gear is also 2000 rpm. The speed of the fourth gear output gear is the same (2000 revolutions) as the output shaft, the speed of the fourth gear input gear is 4000 revolutions, and the speed of the third and fourth gear rings is the same (2000 revolutions) as the input shaft. When it is necessary to change from fifth gear (current gear) to fourth gear (target gear), refer to Figure 10 , the fifth gear ring moves to the right under the control of the shift operating mechanism (disengages the fifth gear), and the third and fourth gear rings move right under the control of the shift operating mechanism to press the fourth gear sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com