Tube cutting apparatus and method for cutting mother tubes

A pipe cutting device and pigging technology, which is applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of low operation efficiency and achieve the effect of improving operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

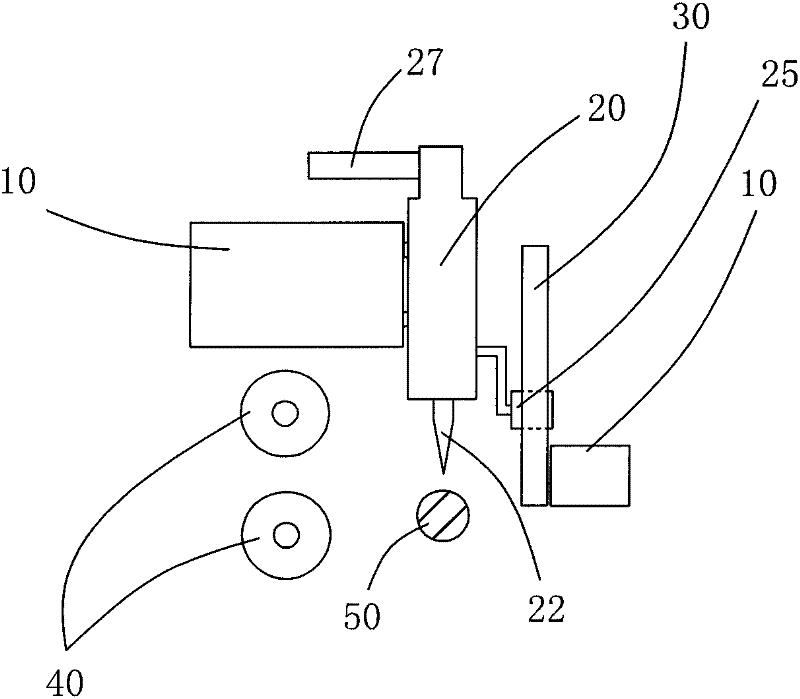

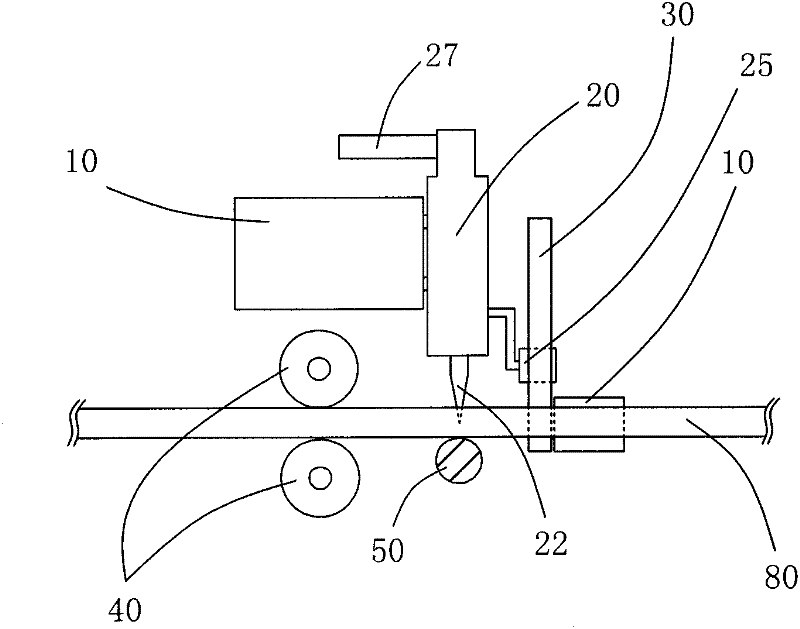

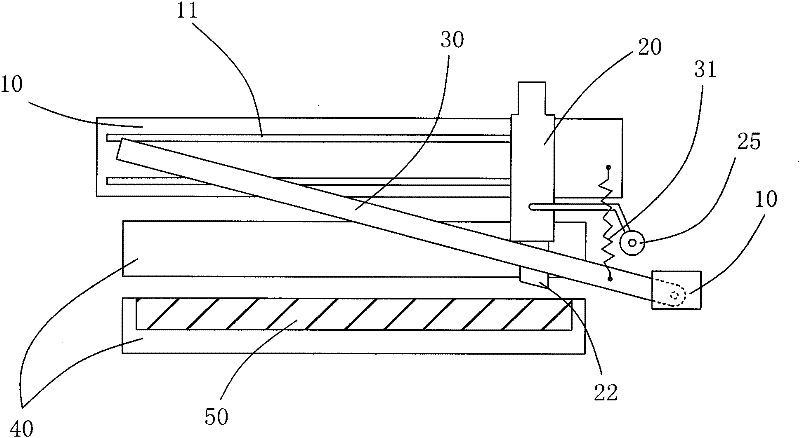

[0025] Please refer to figure 1 To and image 3 , figure 1 A schematic side view of a pipe cutting device according to an embodiment of the present invention; figure 2 yes figure 1 Schematic diagram of the state of cutting the lamp tube with the center tube cutting device; image 3 yes figure 1 Schematic front view of the center-cut tube device. The pipe cutting device of the present embodiment includes: a conveying roller 40 for conveying pigging 80, and said pigging 80 is along its own axial direction (such as figure 2 The left and right directions in the center) are transported to form a transmission path (that is, the space through which the pigging 80 passes during the transmission process); the cutting mechanism 20 comprising a cutter 22 is slidably arranged on the frame 10, and the cutting The sliding track of the mechanism 20 on the frame 10 (please refer to the follow-up Figure 4 to Figure 6 Description) perpendicular to the transmission path; close to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com