Laser detection device and method for gear parameters

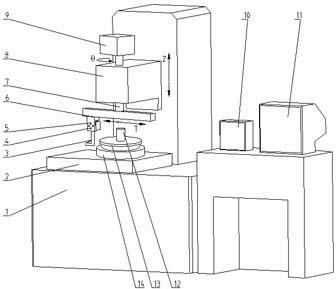

A laser detection and gear technology, which is used in the parameter detection of external gears, worm gears and worms, gear parameter laser detection devices, gear cutters, and internal gears. , to achieve the effect of improving detection speed, reducing measurement error and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Example 1: Parameter detection of large internal gear

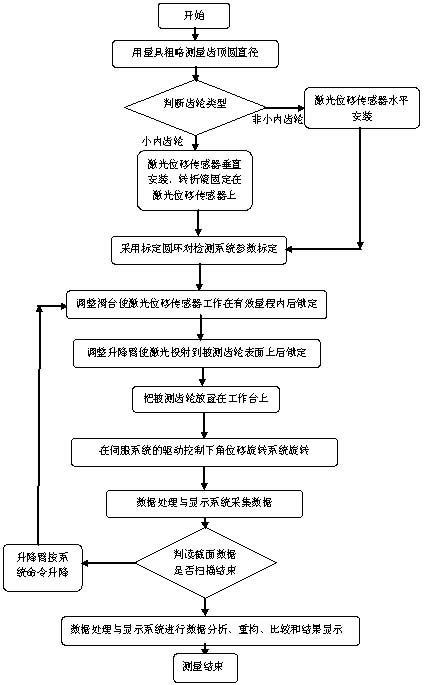

[0066] For large internal gears, press image 3 Step measurement:

[0067] 1) First, roughly measure the tooth tip diameter and gear thickness of the measured gear 14 with a measuring tool and input them into the data processing and display system 11 for the laser displacement sensor 4 to determine the amount of expansion and contraction on the sliding table 6 and the lifting arm 8 Drive the lift of the sliding table 6;

[0068] 2) According to the rough measurement, the gear type is the large internal gear, small internal gear or external gear. If it is larger than 120mm, it is a large internal gear. Only the 120mm±10mm produced by Keyence Corporation of Japan that is compatible with the measurement of the large internal gear is installed. The laser displacement sensor does not need to install a turning mirror.

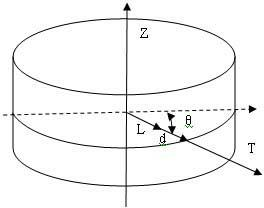

[0069] 3) and press Figure 7 The calibration detection of the large internal gear is shown, that is, the ca...

Embodiment 2

[0094] Example 2: Detection of small internal gear parameters

[0095] For the small internal gear, press image 3 Step measurement:

[0096] 1) First, roughly measure the tooth tip diameter and gear thickness of the measured gear 14 with a measuring tool and input them into the data processing and display system 11 for the laser displacement sensor 4 to determine the amount of expansion and contraction on the sliding table 6 and the lifting arm 8 Drive the lift of the sliding table 6;

[0097] 2) According to the gear type, it is a large internal gear, a small internal gear or an external gear, such as a small internal gear less than 120mm, such as Figure 4 The shown light path turning mirror and the laser displacement sensor are rigidly connected to the bracket 5 to realize synchronous rotation with the laser displacement sensor; the reflection surface of the turning mirror and the beam emitted by the laser displacement sensor are 45°, and the measuring surface formed by the meas...

Embodiment 3

[0125] Example 3: External gear parameter detection

[0126] For external gear, press image 3 Step measurement:

[0127] 1) First, roughly measure the tooth tip diameter and gear thickness of the measured gear 14 with a measuring tool and input them into the data processing and display system 11 for the laser displacement sensor 4 to determine the amount of expansion and contraction on the sliding table 6 and the lifting arm 8 Drive the lift of the sliding table 6;

[0128] 2) According to the gear type on the thick side, which is large internal gear, small internal gear or external gear, such as external gear, only the laser displacement sensor that matches with the external gear is installed, and no turning mirror is required.

[0129] 3) and press Figure 7 The calibration test of the external gear is shown, that is, the calibration ring is used to calibrate the parameters of the detection system; the laser displacement d(t), the linear displacement z(t) of the lifting arm, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com