Centralizer and drill rod and engineering machine applying same

A technology for construction machinery and drill pipes, which is applied in the fields of construction machinery, drill pipe structures, and righting devices, and can solve problems such as insufficient drilling accuracy, hole inclination, and large telescopic travel of drill pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

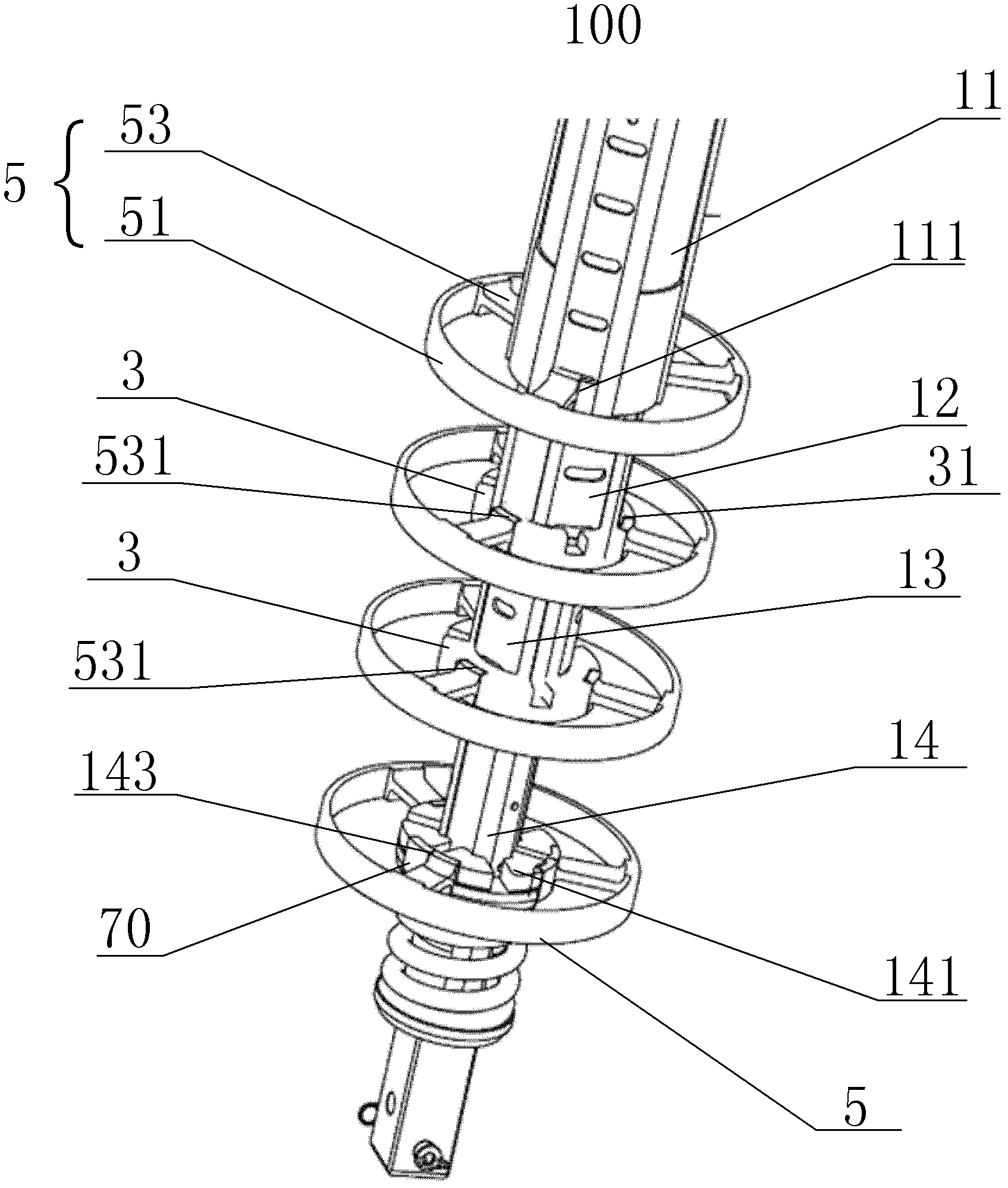

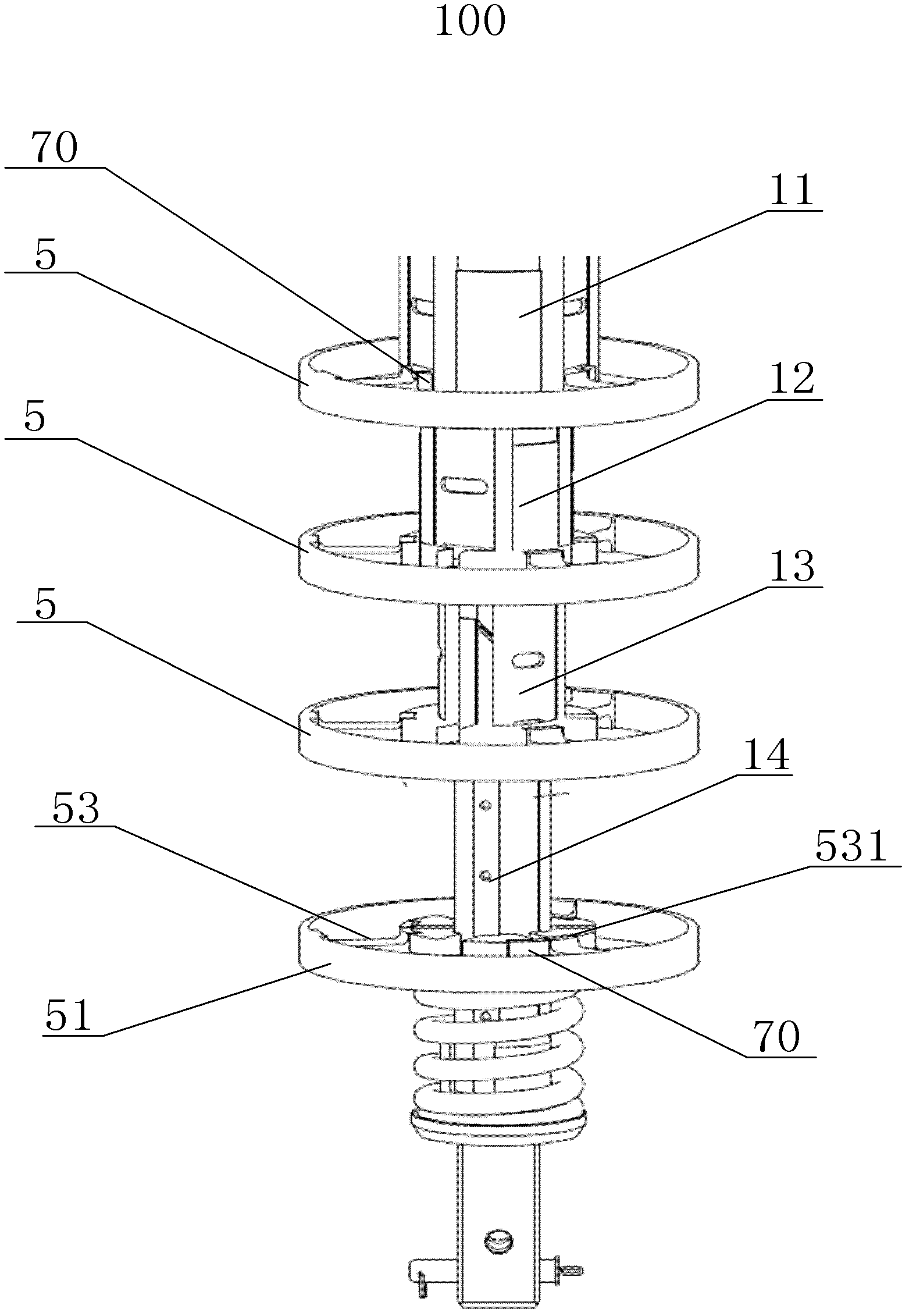

[0017] The following will be combined with the preferred embodiment of the present invention figure 1 and figure 2 , The technical solutions in the embodiments of the present invention are clearly and completely described.

[0018] The present invention provides a drill rod structure 100, which is used in construction machinery such as rotary drilling rigs. The drill rod structure 100 includes a drill rod, a chuck 3 and a centralizing device. The drill rod structure 100 in the preferred embodiment of the present invention includes four drill rods, namely a first drill rod 11, a second drill rod 12, a third drill rod 13, and a fourth drill rod 14. The four drill rods Socket them together in turn.

[0019] The first drill rod 11 is the outer rod of the drill rod structure 100. The first drill rod 11 has an open end, and a peripheral wall 110 adjacent to the open end is provided with three clamping grooves 111. The clamping grooves 111 are used to fix the centralizer 5.

[0020] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com