Enhanced reinforced plastic inspection well

A plastic inspection well and enhanced technology, which is applied in water conservancy projects, waterway systems, artificial islands, etc., can solve the problems of inconvenient cleaning by manual methods, insufficient strength of plastic castings, and not easy to clean at any time, so as to achieve settlement that is not easy to move and stable Strong and convenient connection, reducing the frequency of manual cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment is described by taking the straight-through plastic inspection well as an example.

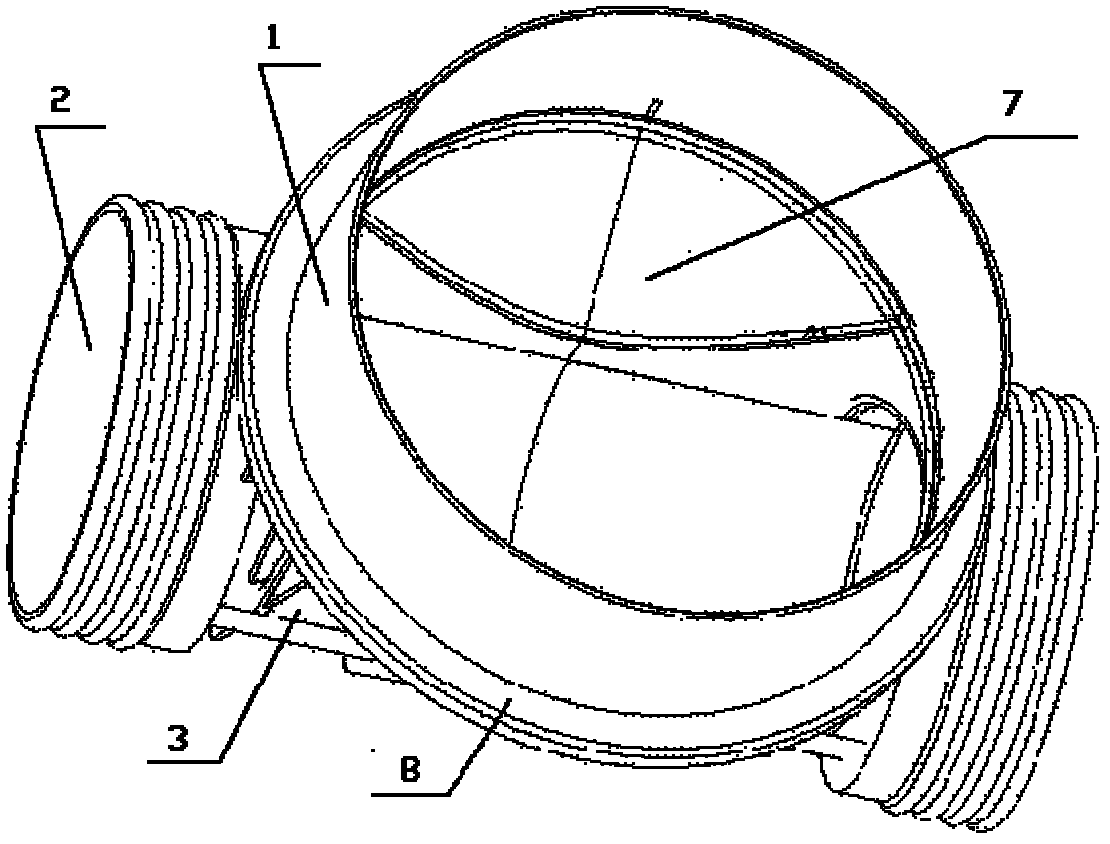

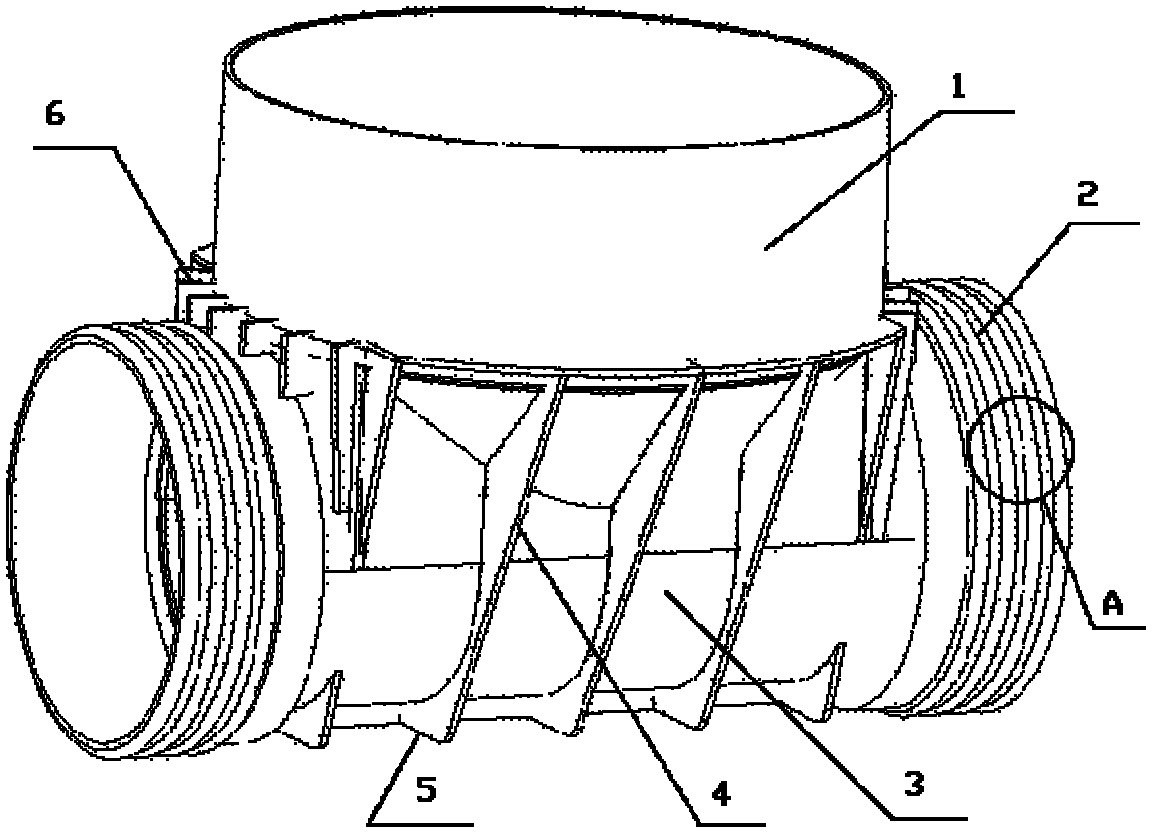

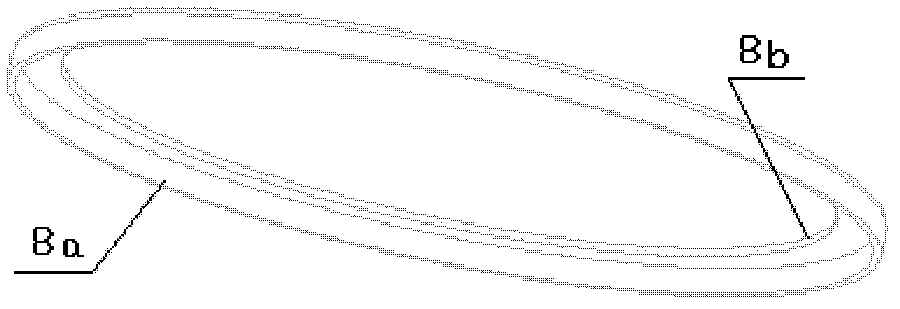

[0031] combine Figure 1 to Figure 5 ,as the picture shows, figure 1 It is a schematic diagram of the structure of the inspection well seat with retaining ring in the present invention; figure 2 It is a schematic diagram of the structure of the well seat of the inspection well without retaining ring in the present invention; image 3 It is a structural schematic diagram of the inspection well retaining ring of the present invention; Figure 4 yes figure 2 The enlarged schematic diagram of part A, that is, the schematic diagram of the corrugated reinforcing rib structure at the branch pipe interface, Figure 5 It is a schematic diagram of the mechanism at the bottom of the inspection well of the present invention.

[0032]Reinforced reinforced plastic inspection well, including well base 3, well head 1 and branch pipe interface 2, well head 1 is an inner socket con...

Embodiment 2

[0036] The other structures are the same as in Embodiment 1, except that there are further corrugated reinforcing ribs 2a arranged around the circumference of the branch pipe joint 2 on the outer surface of the branch pipe joint 2 . The stress area of the corrugated rib 2a is 2.5 times that of the flat wall socket, and the force per unit area is relatively small, which greatly enhances the steel of the well seat ring and increases the strength of the load. The crest of the corrugated rib 2a is an arc, and the load is When the force is applied, the direction of the force is changed, so that the force can be decomposed and carried evenly; the present invention can further arrange reinforcing ribs in the axial direction of the branch pipe interface to increase the rigidity.

Embodiment 3

[0038] The other structures are the same as in Embodiment 1 or Embodiment 2, except that there is a groove transition structure 7 at the connection between the wellhead and the well seat on the inner wall of the inspection well. The groove transition structure 7 refers to the use of a concave slope at the connection between the inner wall of the cylindrical wellhead 1 of the inspection well and the inner wall of the well base 3, and the center of the wellhead 1 is lower than the edge of the wellhead 2, generally adopting an arc-shaped groove design; The arc-shaped groove with a certain inclination is conducive to the falling of falling objects. The arc-shaped groove has no edges, and the falling objects will not be blocked when falling, which greatly reduces the frequency of manual cleaning, reduces labor intensity, and saves maintenance costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com