Method for controlling high-speed running of direct drive industrial sewing machine

A technology of industrial sewing machines and control methods, which is applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve problems such as low sewing efficiency and pattern reduction, and achieve the goal of solving pattern reduction, ensuring sewing quality, and improving sewing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

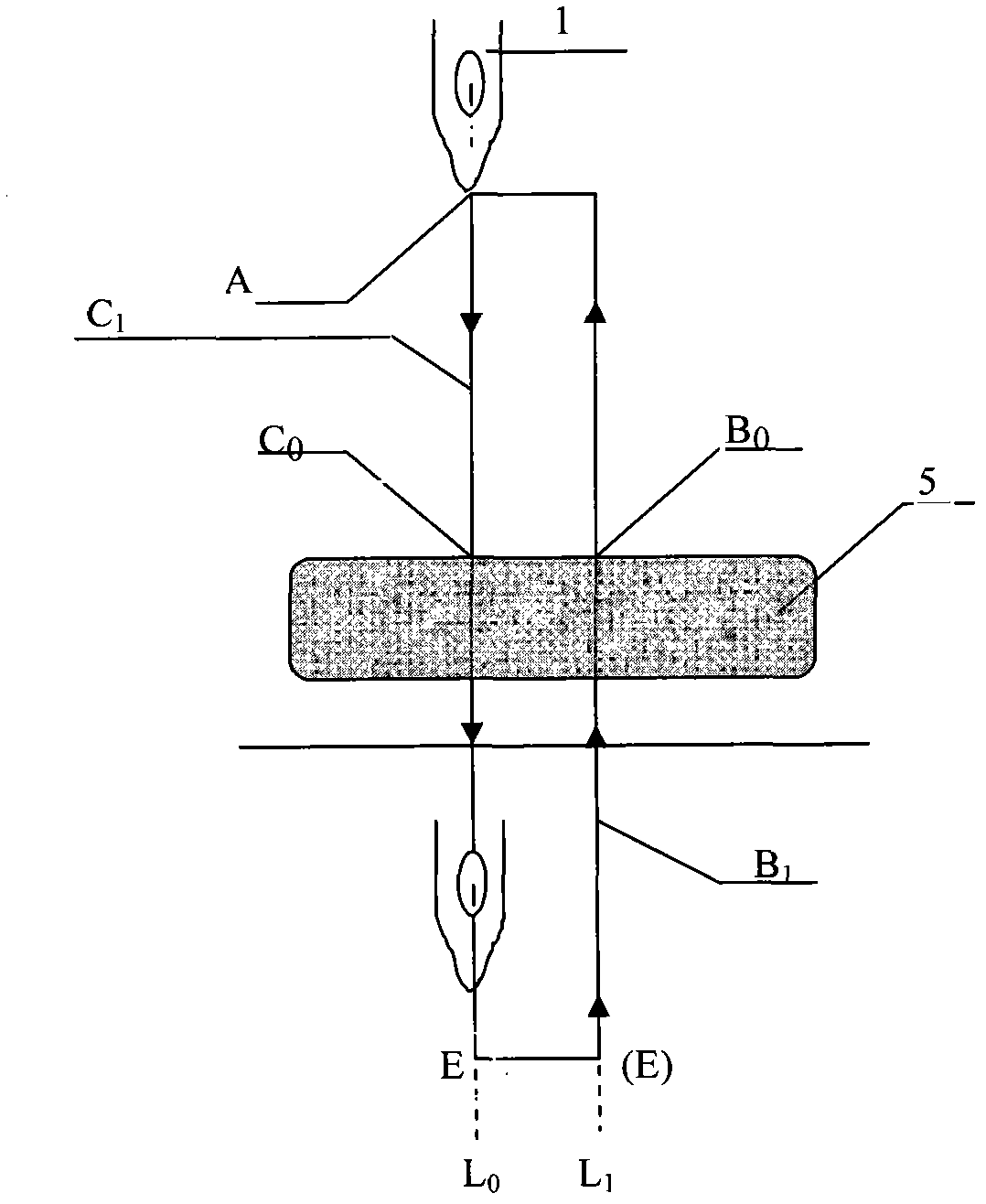

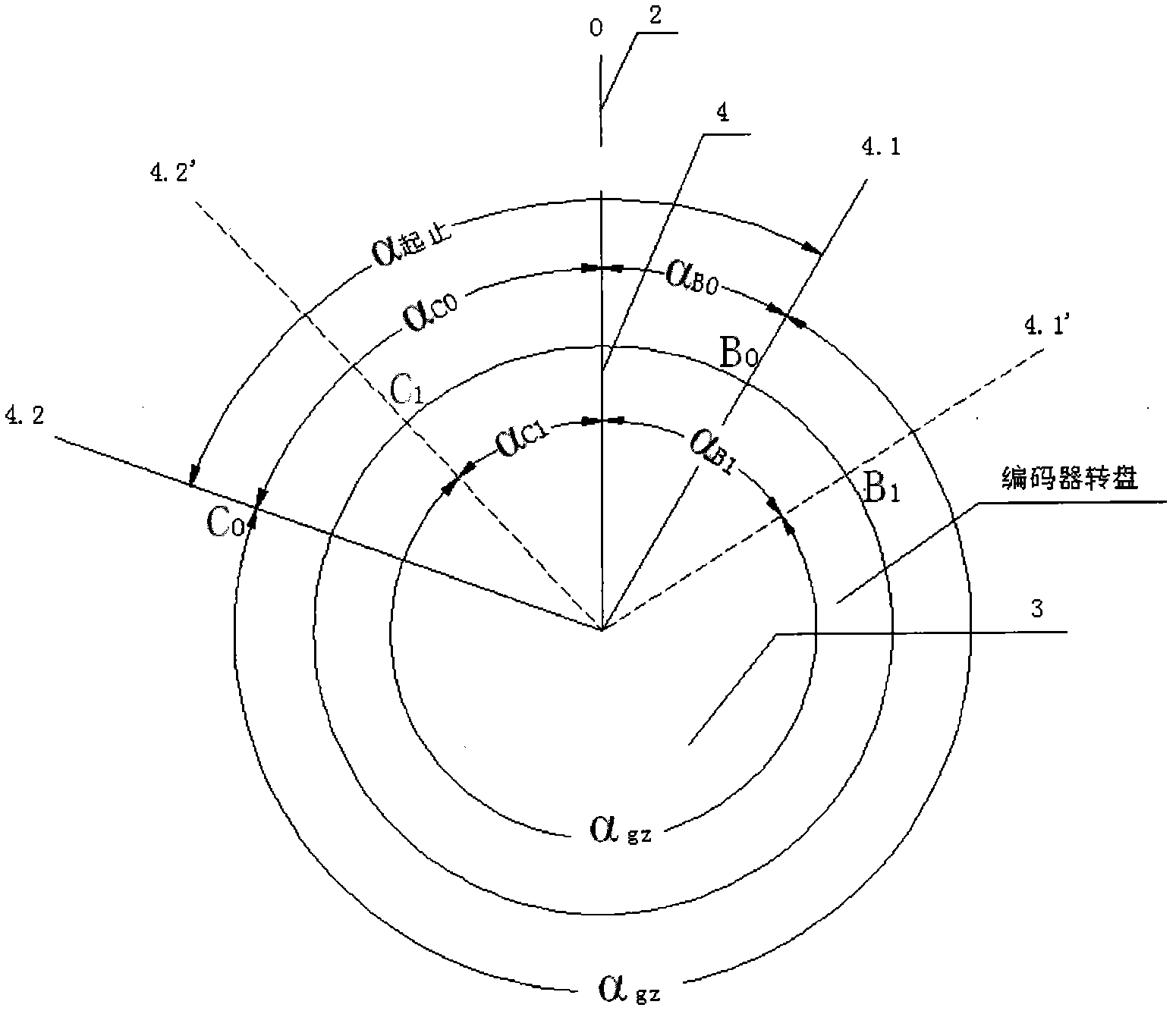

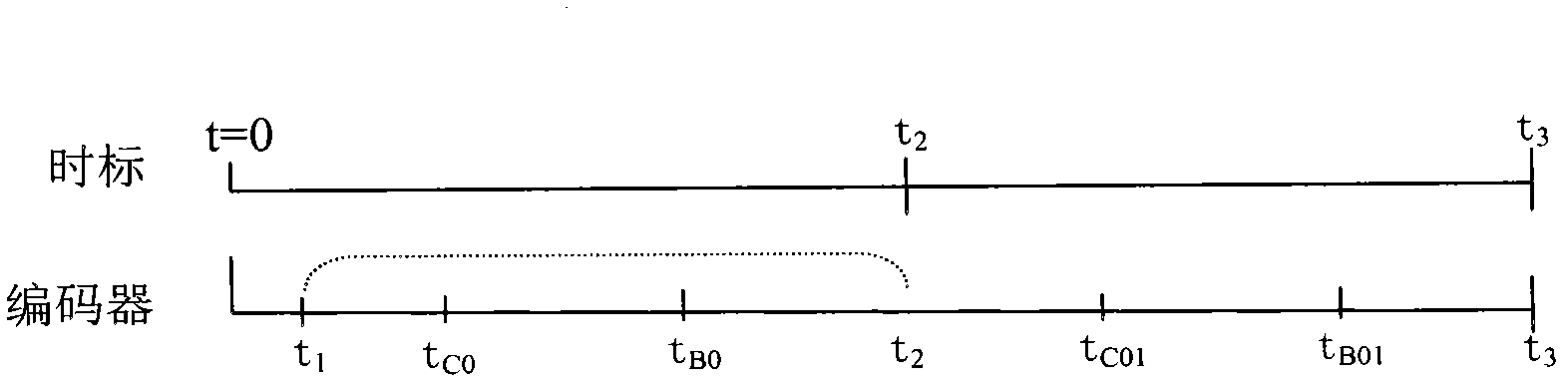

[0076] see Figure 1-Figure 4 As shown, the high-speed motion control method of the direct-drive industrial sewing machine provided by the present invention improves the sewing speed and sewing effect by dynamically adjusting the cloth feeding time of the X-axis and Y-axis of the sewing machine, mainly under the condition of not feeding cloth, manually Determine the angular relationship between the up and down movement of the needle bar, the up and down movement of the main shaft and the encoder during the sewing process, and the control method is realized through the following steps,

[0077] Step 1. Turn each axis of the sewing machine to the initial zero position; the needle point A of the needle bar 1 is at the initial zero position, and the distance between the needle point A and the needle plate is 15mm. At this time, the turntable reference line 4 of the sewing machine main shaft encoder 3 is in a vertical position, and the turntable reference line 4 coincides with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com