Lactococcus lactis fermented at low temperature and method for preparing yoghurt by using Lactococcus lactis

A Lactococcus lactis, low-temperature technology, applied in the field of bioengineering, can solve the problems of increasing the thermal energy cost of the factory, high fermentation temperature of yogurt, and flavor precipitation of whey, etc., and achieves the effects of good curdling performance, short fermentation period and high viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of sterilized milk: Add 0.3kg of sucrose to 4.6kg of fresh milk or reconstituted milk, dissolve and filter to remove impurities, then preheat to 60°C, then homogenize at 15MPa for 10min, and then sterilize the obtained homogeneous liquid at 95°C for 5min , and then cooled to 30°C for later use.

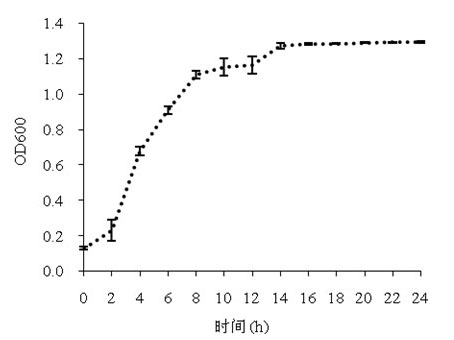

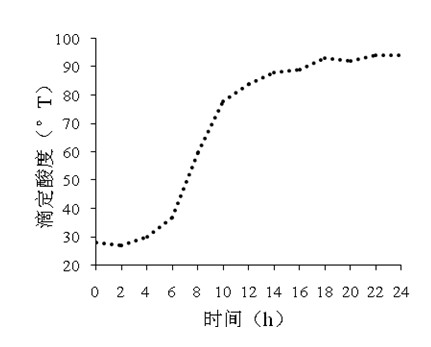

[0040] Yogurt preparation: insert Lactococcus lactis 3 rings of the present invention into 0.04kg sterilized milk, cultivate for 24h so that the cell number is 10 8 ~10 9 Between cfu / mL, take 0.03kg and inoculate it into spare sterilized milk, culture it at 25°C until curdling, then cool it down to 4°C, store it in a refrigerator at 0-5°C, and ripen it for 24 hours.

Embodiment 2

[0049] Preparation of sterilized milk: add 0.40kg sucrose to 4.60kg fresh milk or reconstituted milk, dissolve and filter to remove impurities, then preheat to 65°C, then homogenize at 25MPa for 20min, and then sterilize the obtained homogeneous liquid at 95°C for 5min , and then cooled to 30°C for later use.

[0050] Yogurt preparation: insert Lactococcus lactis 3 rings of the present invention into 0.04kg sterilized milk respectively, cultivate for 24h to make the cell number at 10 8 ~10 9 Between cfu / mL, take 0.03kg each and inoculate it into spare sterilized milk, culture it at 25°C until curdling, then cool it down to 4°C, store it in a freezer at 0-5°C, and ripen it for 24 hours.

Embodiment 3

[0063] Preparation of sterilized milk: Add 0.20kg of sucrose to 4.80kg of fresh milk or reconstituted milk, dissolve and filter to remove impurities, then preheat to 62°C, then homogenize at 20MPa for 15min, and then sterilize the obtained homogeneous liquid at 95°C for 5min , and then cooled to 30°C for later use.

[0064] Yogurt preparation: insert Lactococcus lactis 3 rings of the present invention into 0.04kg sterilized milk, cultivate for 24h so that the cell number is 10 8 ~10 9 Between cfu / mL, inoculate 0.03kg into spare sterilized milk, culture at 25°C until curdling, then cool to 4°C, store in a refrigerator at 0-5°C, and ripen for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com