Detoxification control system for post-process of absorbed tetanus vaccine

A technology for control systems and vaccines, applied in biomass post-processing, biochemical instruments, biochemical equipment and methods, etc., which can solve the problems of inconsistent temperature, inability to quickly and accurately know temperature, product exposure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

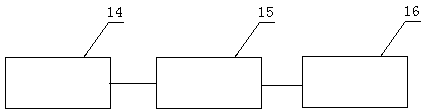

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] like figure 1 , figure 2 As shown, a process detoxification control system after adsorption of tetanus vaccine, a plurality of detoxification tanks with at least two layers of structure are connected in parallel with a temperature control device, and each detoxification tank end is equipped with a fully enclosed upper magnetic stirring device, so The post-adsorption tetanus vaccine process detoxification control system includes a stirring control subsystem and a temperature control subsystem, and the stirring control subsystem includes a stirring speed setting module 14 and a stirring time setting module 15 connected to it, a stirring time Interval setting module 16;

[0016] The temperature control subsystem includes: a control center module 1 at the temperature control device end, a data processing module 2, a temperature recording module 3, a data storage modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com