Field detection system for detecting partial discharge of cable and joint

A partial discharge and on-site detection technology, applied in the direction of testing dielectric strength, etc., can solve problems such as insulation defects, partial discharge, and insulation material aging, and achieve the effect of ensuring safe and reliable operation, removing on-site interference, and discovering timely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

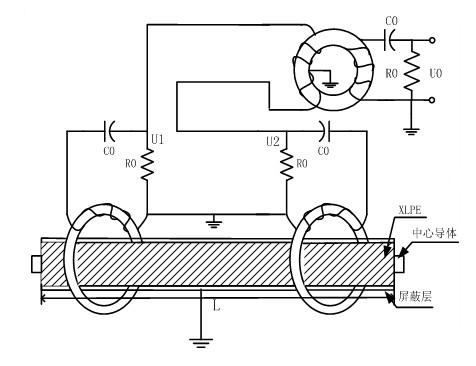

[0013] like figure 1 , figure 2 , image 3 As shown, the on-site detection system for cable and joint partial discharge of the present invention, on the basis of a large number of experiments, constantly sums up experience, implements scientifically, design scientifically, and analyzes strictly to obtain this system, which includes hardware devices and software systems. The hardware device includes a broadband differential current sensor, a signal conditioning module, and a data acquisition card. The broadband differential current sensor is composed of a magnetic core, a Rogowski coil, a filtering and sampling unit and an electromagnetic shielding box. The signal conditioning module includes a trigger signal circuit and an amplifier. The software system is labVIEW software of virtual instrument technology.

[0014] Below in conjunction with embodiment for further explanation.

[0015] A wide-band differential current sensor is developed on the basis of a wide-band curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com