Safety valve for polypropylene loop reactor

A loop reactor and polypropylene technology, applied in the field of safety valves, can solve problems such as blocked inlets, medium stagnation, and working effectiveness, and achieve the effects of avoiding direct impact, easy maintenance, and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

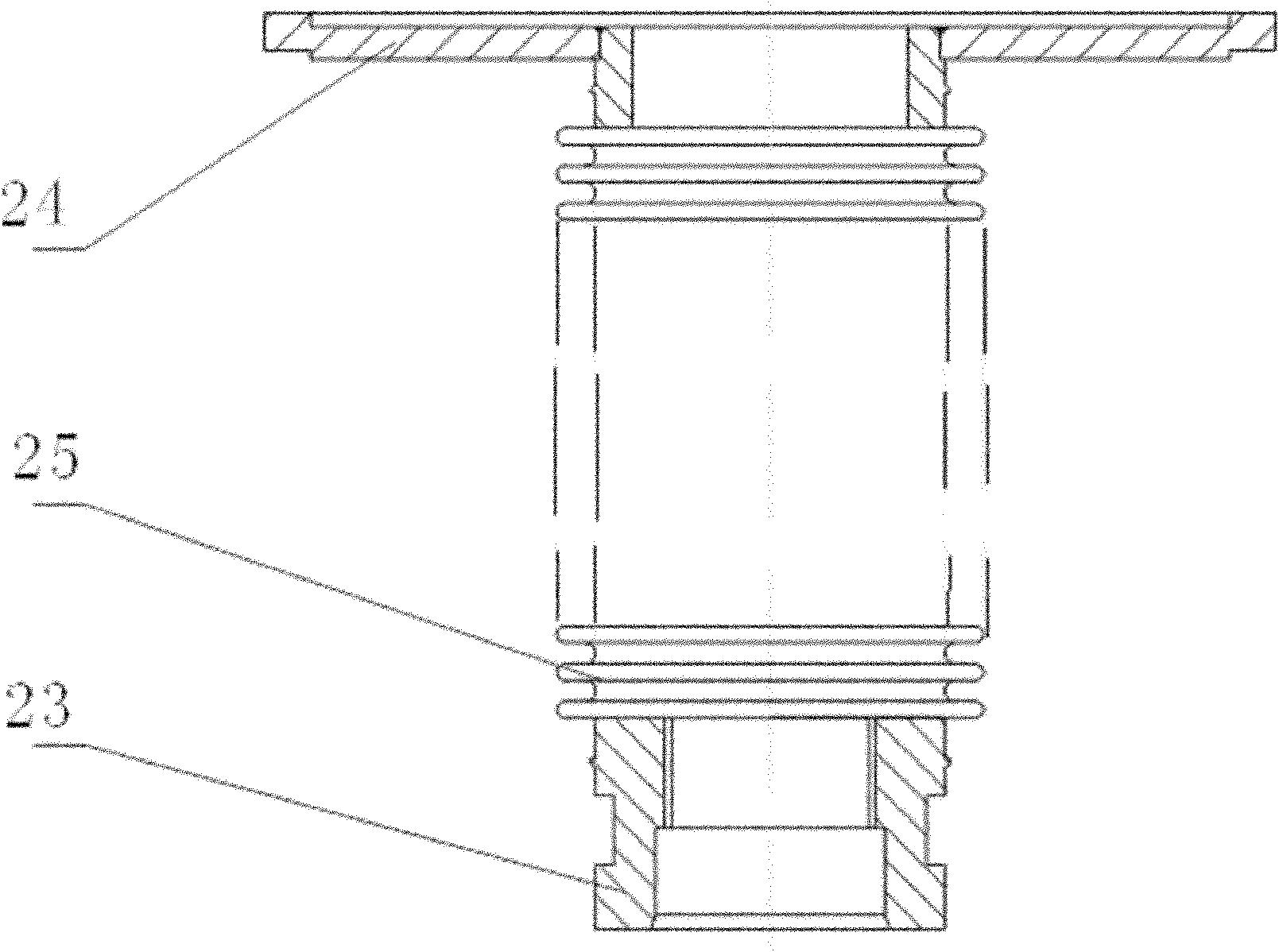

[0020] Such as figure 1 The bellows assembly shown includes a lower joint 23, an upper joint 24 with a hole in the middle, and a bellows 25.

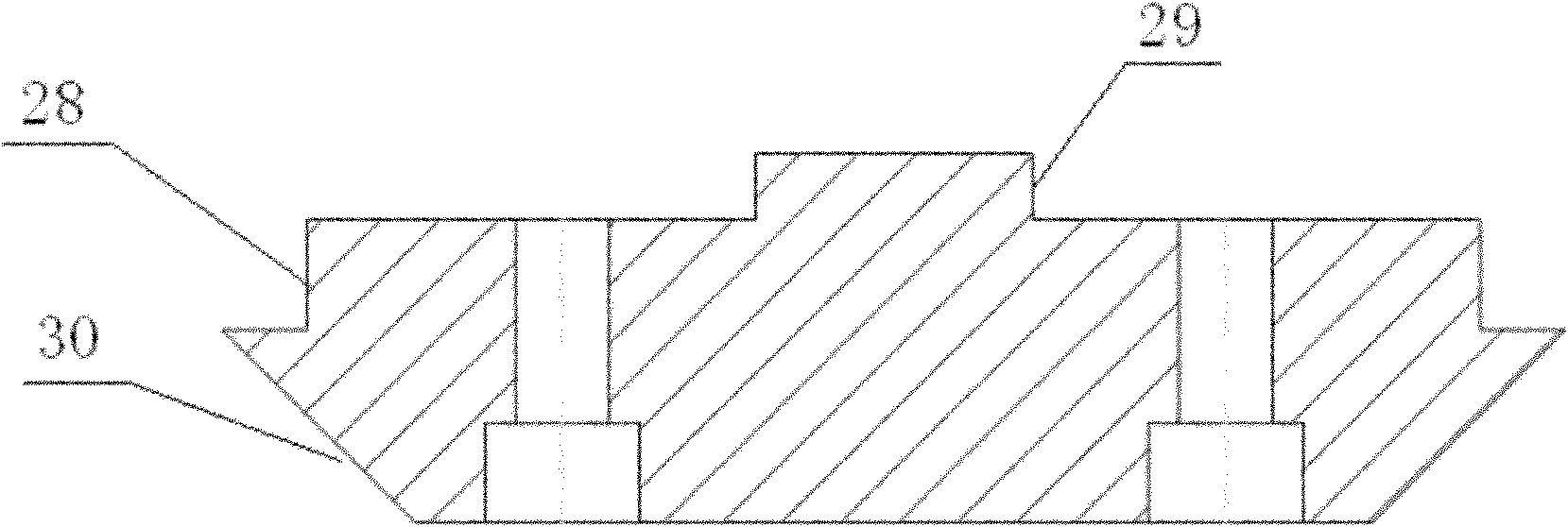

[0021] figure 2 The structure diagram of the pressure ring 4 is given. The pressure ring 4 is a circular disc with a circular table 28 on the upper end. A boss 29 is machined on the upper surface of the circular table 28.

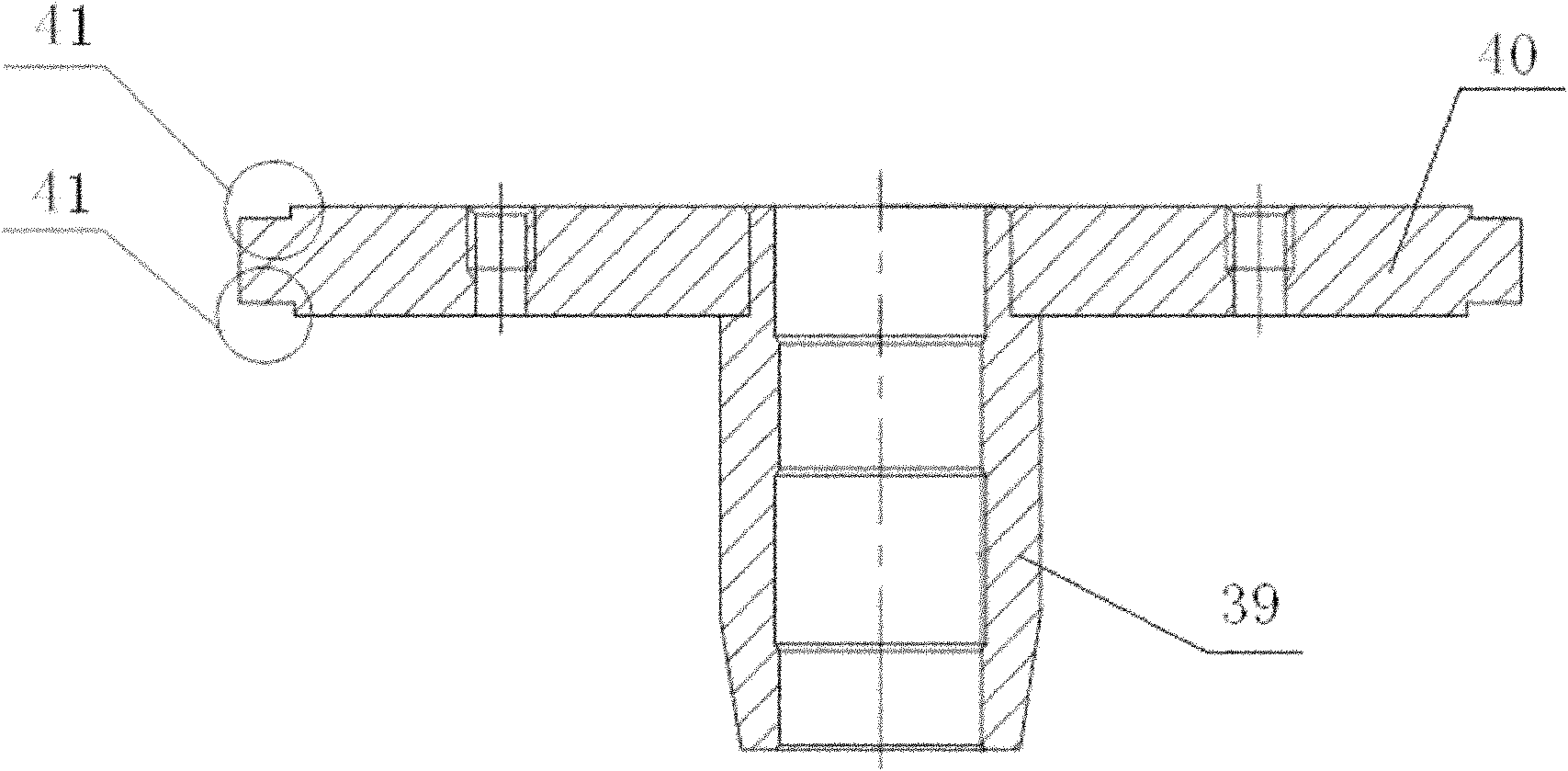

[0022] Such as image 3 As shown, the main body of the guide sleeve 11 is a cylinder 39, the upper end of the cylinder 39 is fixedly installed with a circular pressure plate 40, and the upper and lower edges of the circular pressure plate 40 are provided with circular grooves 41.

[0023] Such as Figure 4 As shown, the upper end of the valve disc 2 is processed into a cylinder 31, the lower end side wall is processed into a conical surface 32, the lower surface of the valve disc 2 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com