High load response supercharged engine

A supercharged engine, high-load technology, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems affecting engine load response speed, etc., achieve simple structure, eliminate hysteresis, and high load response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

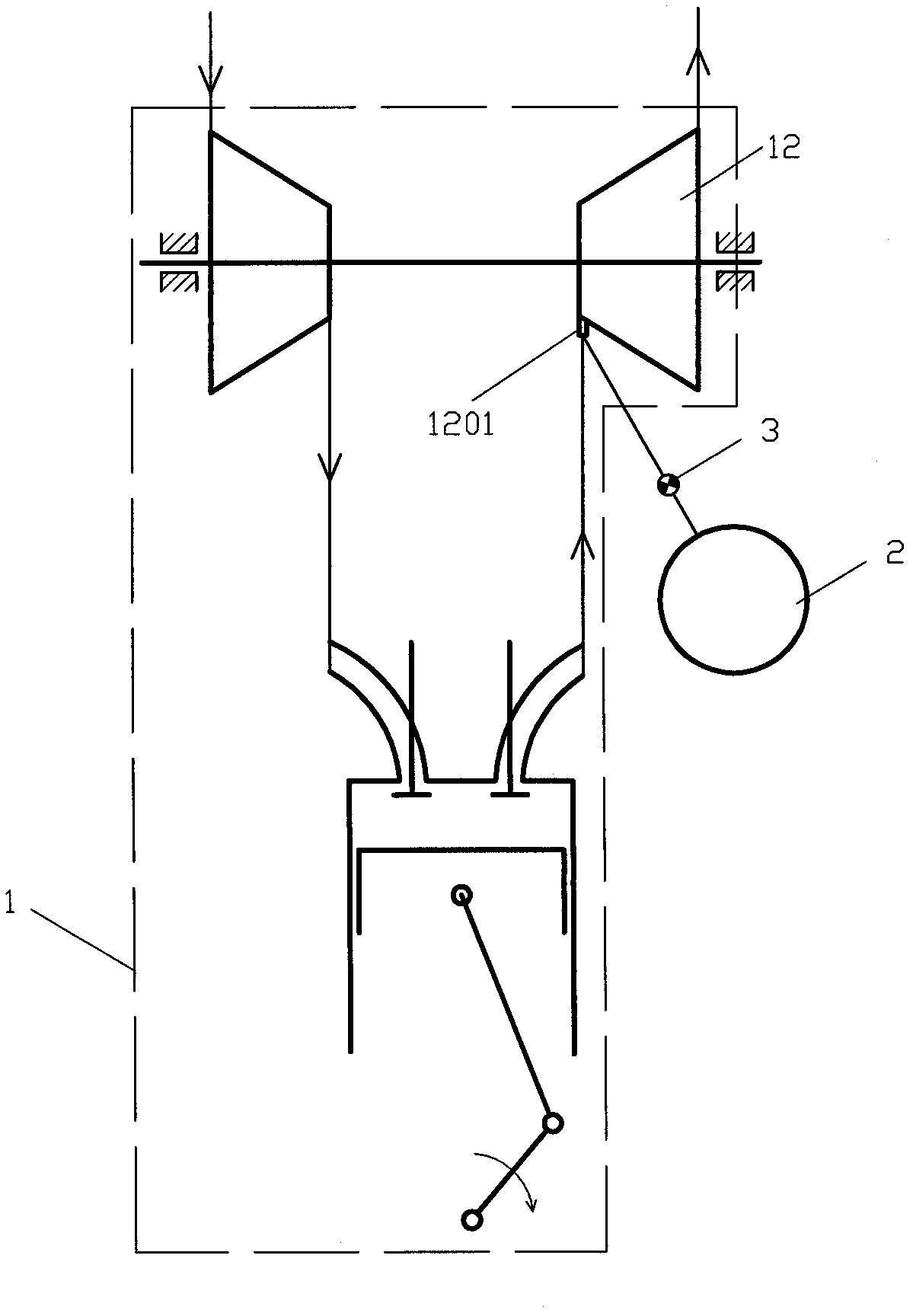

Embodiment 1

[0029] Such as figure 1 The shown high load response supercharged engine includes a supercharged engine 1 and an air storage tank 2, the gas storage tank 2 is connected to the power turbine of the power turbine 12 of the supercharged engine 1 through the gas storage tank control valve 3 The gas inlet 1201 communicates.

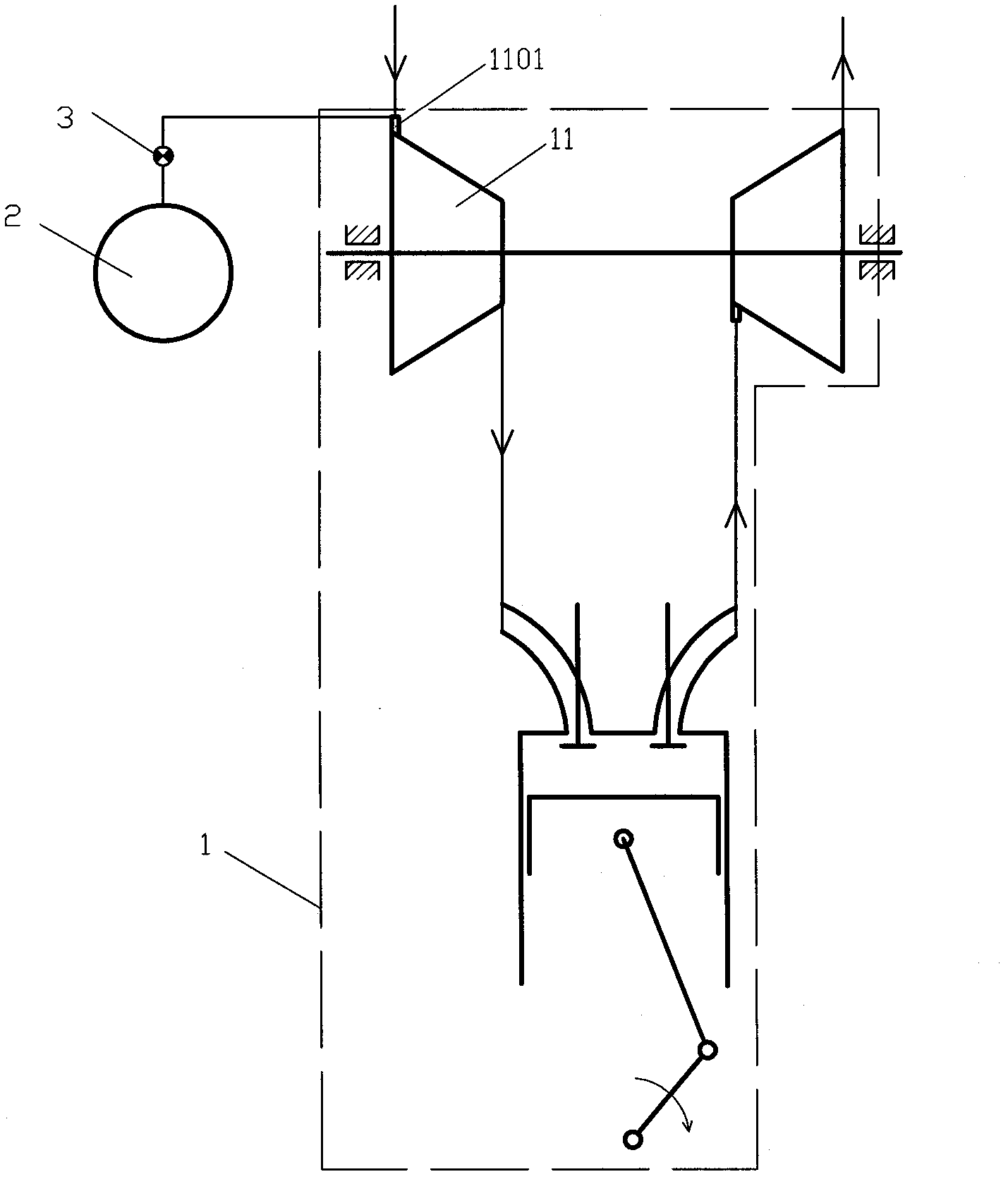

Embodiment 2

[0031] Such as figure 2 The high load response supercharged engine shown includes a supercharged engine 1 and an air storage tank 2, the gas storage tank 2 is connected to the compressor gas inlet of the compressor 11 of the supercharged engine 1 through the gas storage tank control valve 3 1101 connected.

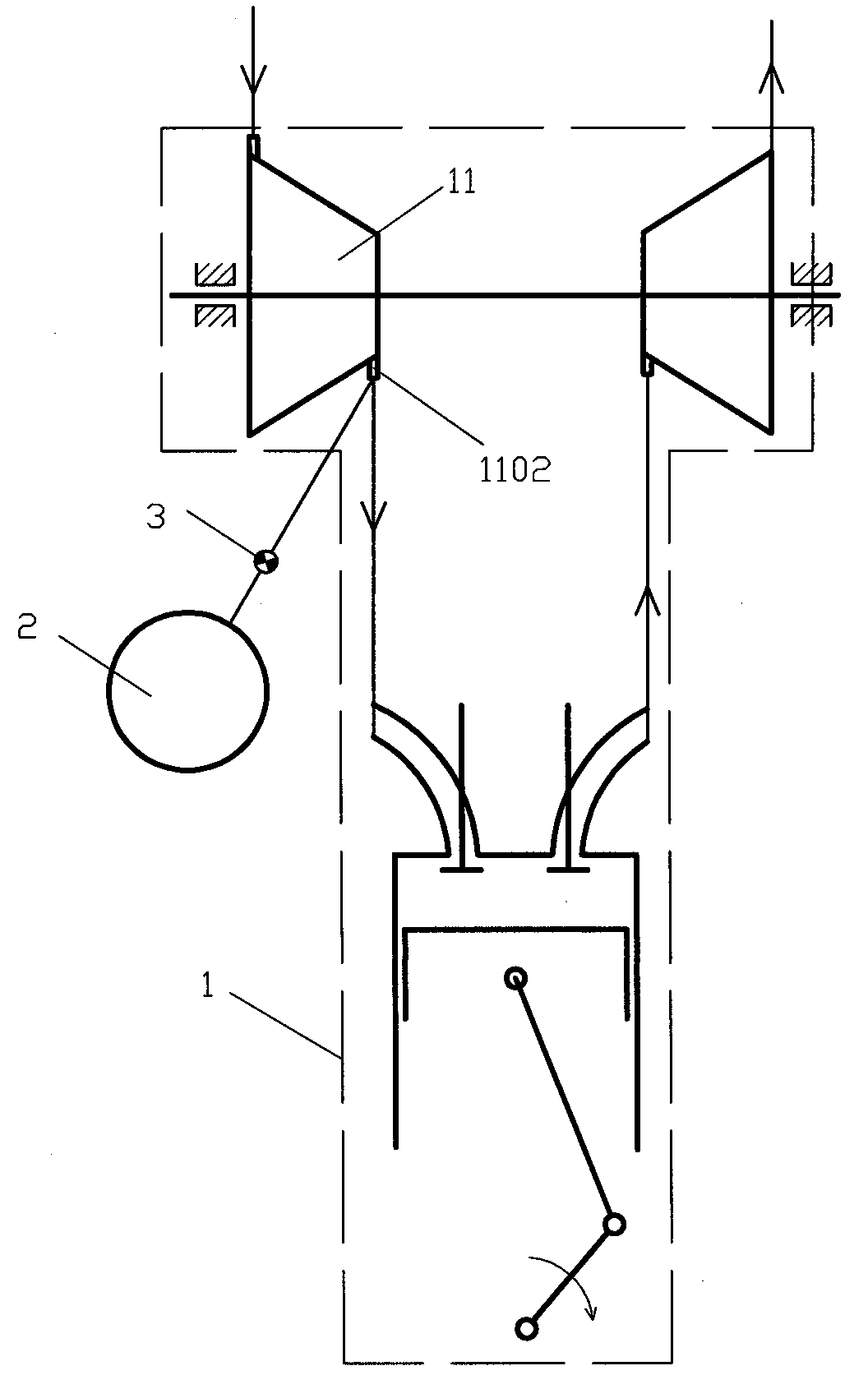

Embodiment 3

[0033] Such as image 3 The high load response supercharged engine shown includes a supercharged engine 1 and an air storage tank 2, the gas storage tank 2 is connected to the compressor gas outlet of the compressor 11 of the supercharged engine 1 through the gas storage tank control valve 3 1102 connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com