Glass sight glass windows for laundry washing and/or drying appliances

A technology for clothes washing and viewing holes, which is applied to washing devices, household utensils, household clothes dryers, etc. It can solve the problems of longitudinal sliding of glass viewing holes, reduced effectiveness of door components, and misalignment of glass viewing holes, so as to improve safety work conditions, improved reliability, and good fixing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

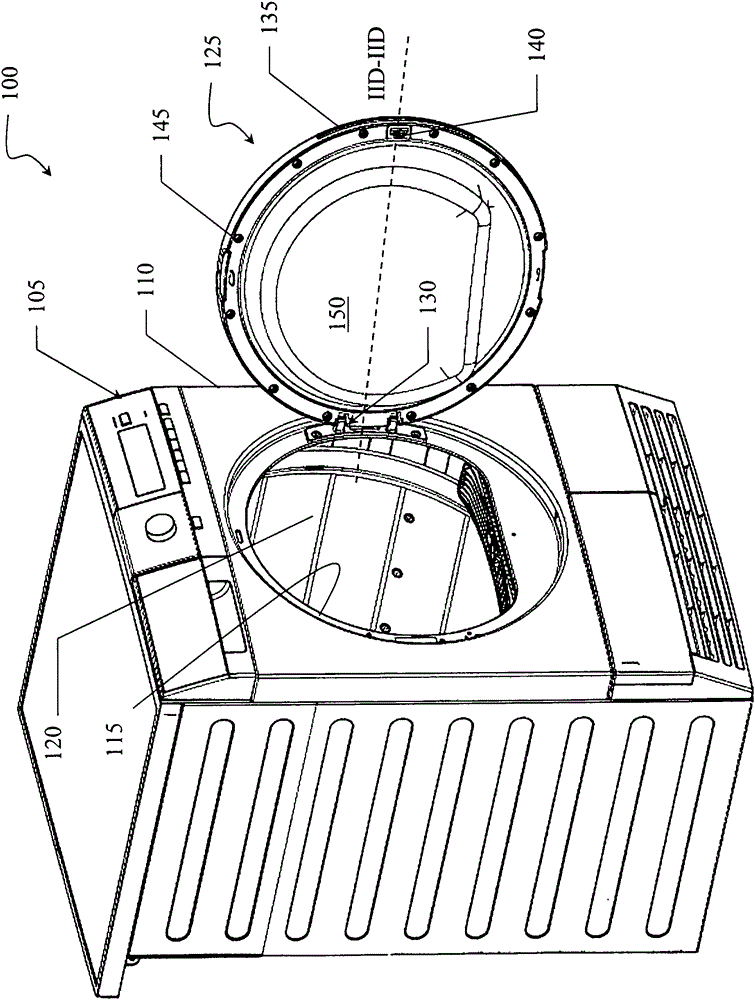

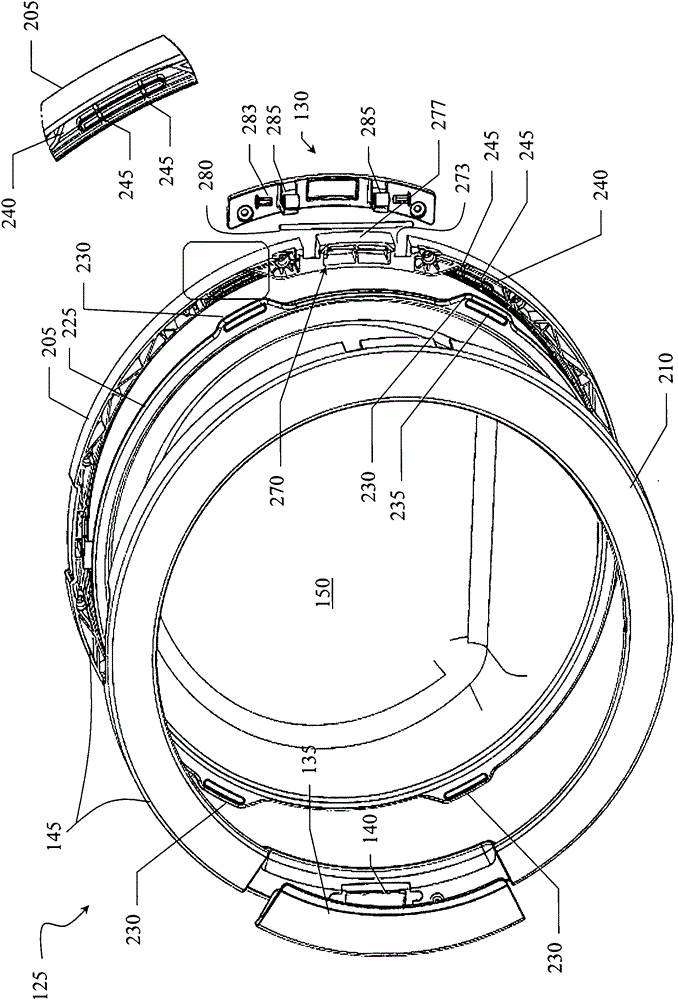

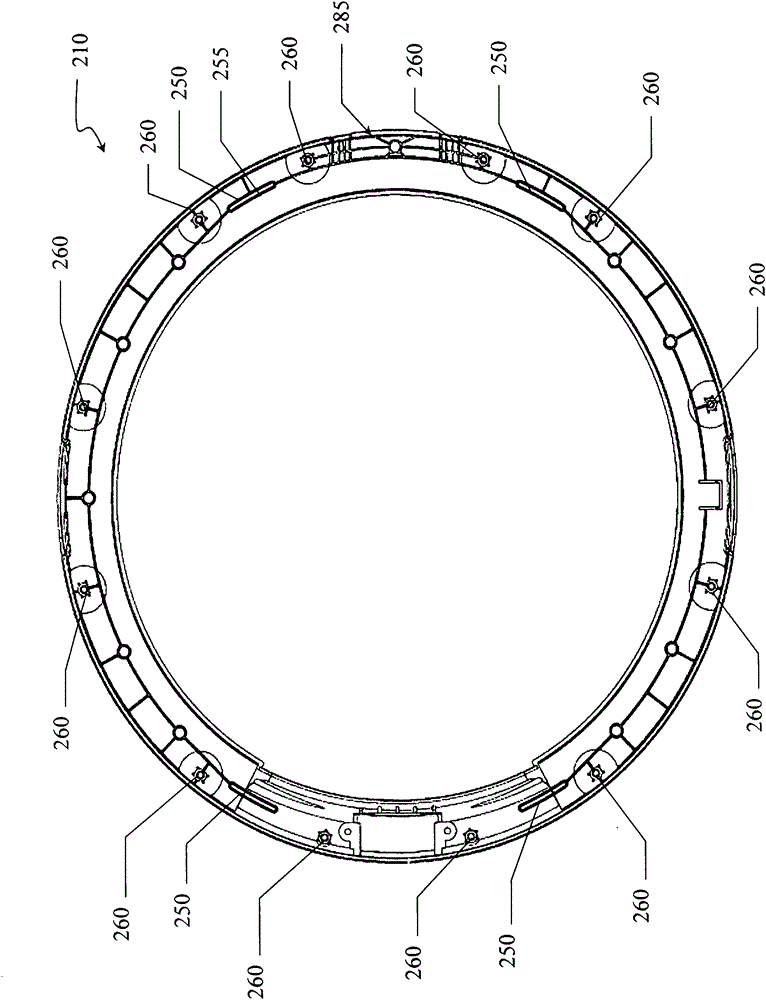

[0035] See attached image, at figure 1 A perspective view of a clothes dryer 100 according to an embodiment of the present invention is shown in . The clothes dryer 100 includes: an outer housing 105, typically fabricated from plastic, metal, or a combination thereof; a front surface 110 of the outer housing 105 includes a circular opening 115 for access to and from the dryer. The drum 120 is rotated and used to load laundry to be dried or remove laundry that has been dried. Circular door 125 (shown in the open state in the figure) is provided for opening and closing circular opening 115; A door hinge 130 in place, and an opening assembly on the opposite side comprising a handle 135 and a hook 140 controlled by the handle for locking the door 125 in the closed state and for unlocking the door so that The door can be opened to open the circular opening 115 . The door 125 further includes an annular frame 145 surrounding a transparent circular glass viewing hole window 150 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com