Front steel turning device of cogging mill

A technology of blanking machine and turning steel, applied in the direction of workpiece manipulation, can solve the problems of high technical level of workers, difficult to align the steel turning position, and potential safety hazards, and achieve accurate and reliable translation and turning actions, as well as stable and accurate lifting and lowering. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

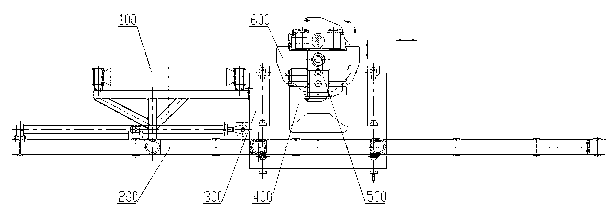

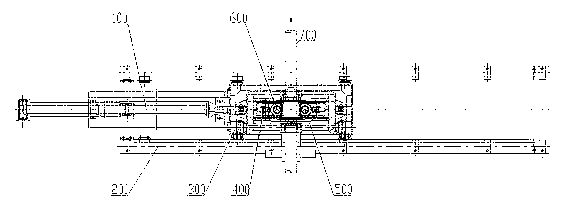

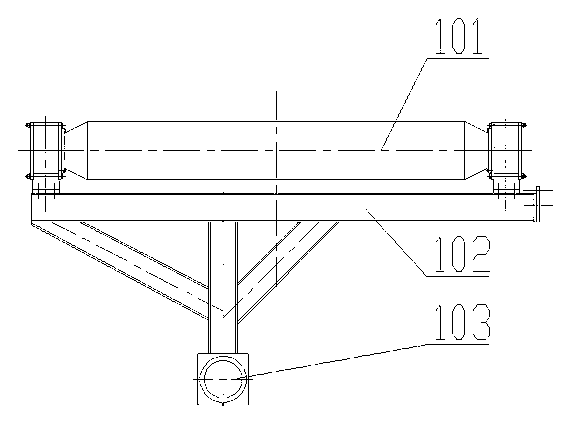

[0035] (refer to figure 1 and figure 2 ) A steel turning device before a blanking machine, including a replacement roller table 100, a base 200, a translation frame 300, a lifting mechanism 400, a turning mechanism 500, and a clamping roller mechanism 600, wherein the replacement roller table 100 is fixedly connected to the translation frame 300, And can move linearly along the base 200, the lifting mechanism 400 is located in the translation frame 300, and the overturning mechanism 500 is located on the side of the lifting mechanism 400, the two can move up and down simultaneously along the inner side of the translation frame 300, the rotating shaft hole of the clamping roller mechanism 600 It is connected with the output shaft of the turning mechanism 500 to realize synchronous rotation with the output shaft of the turning mechanism 500 , a displacement sensor is provided on the translation frame 300 , the lifting mechanism 400 and the pinch roller mechanism 600 , and an en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com