Cutting mechanism of battery pole piece

A battery pole piece cutting technology, which is applied in electrode manufacturing, metal processing, etc., can solve the problems of cutter wear, continuous pole piece cutting, gap increase, etc., and achieve the goals of compensating wear, controlling the size of burrs, and reducing wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further reveal the technical solutions of the present invention, the implementation manners of the present invention will be described in detail in conjunction with the accompanying drawings.

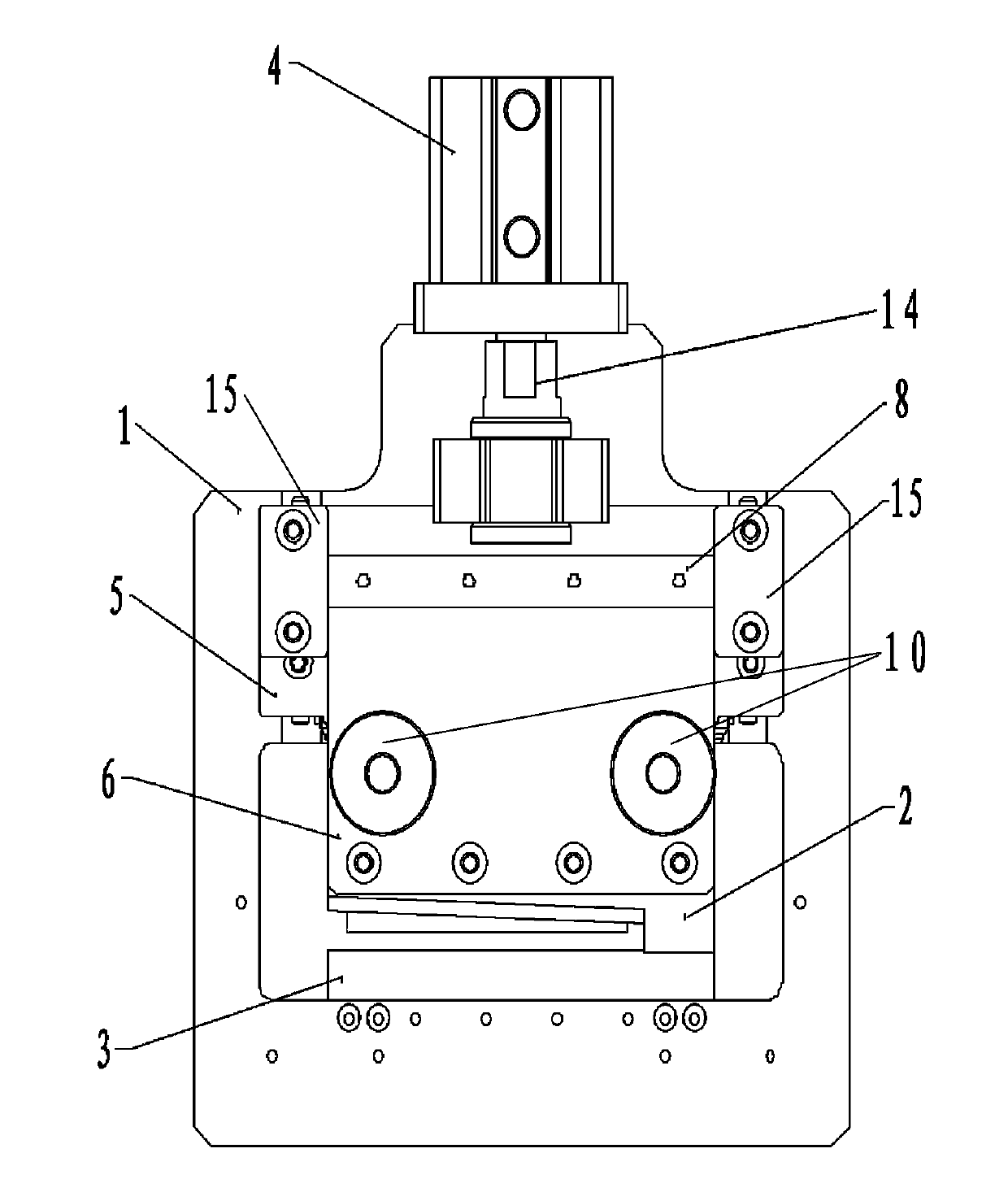

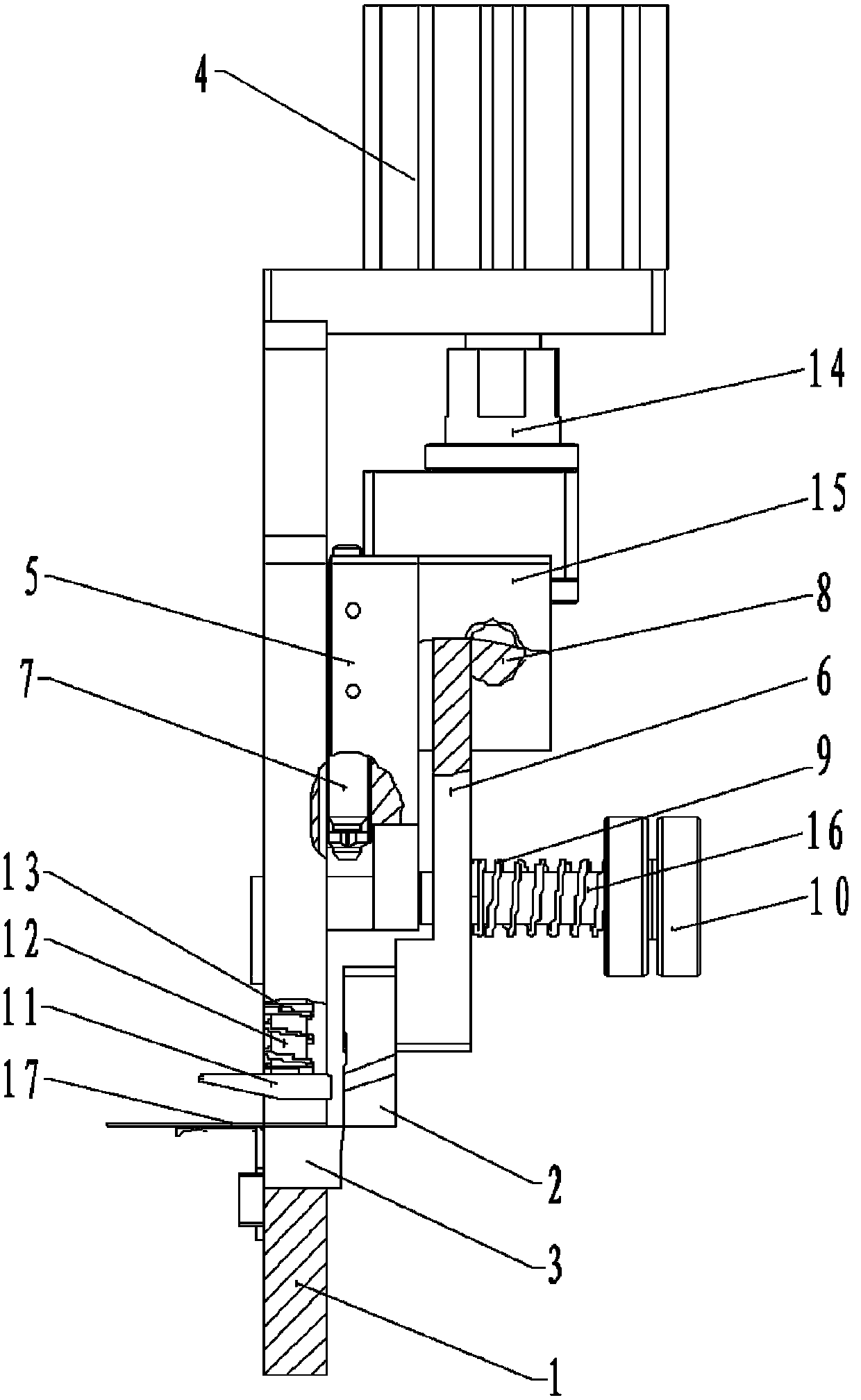

[0014] figure 1 It is the front view of the battery pole piece cutting mechanism of the present invention, figure 2 It is a side view of the battery pole piece cutting mechanism of the present invention. In the figure, it includes: a mounting plate 1; a cross roller guide rail 7, which is installed on the mounting plate 1; a guide rail slide plate 5, the guide rail slide plate 5 is installed on the cross roller guide rail 7, the guide rail slide plate 5 can slide up and down along the cross roller guide rail 7, and the two sides of the guide rail slide plate 5 are fixed with shaft seats 15 which can slide simultaneously with it; the rotating shaft 8, the rotating shaft The two ends of 8 are respectively inserted into the shaft seat 15 and can rotate; the cutter moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com