Oil pumping unit closed-loop control method and system based on underground multiparameter real-time monitoring

A closed-loop control, pumping unit technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as increased production operating costs, power generation status, increase in invalid strokes, etc., to reduce inefficiency or even ineffectiveness The effect of extracting, increasing service life and reducing machine wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

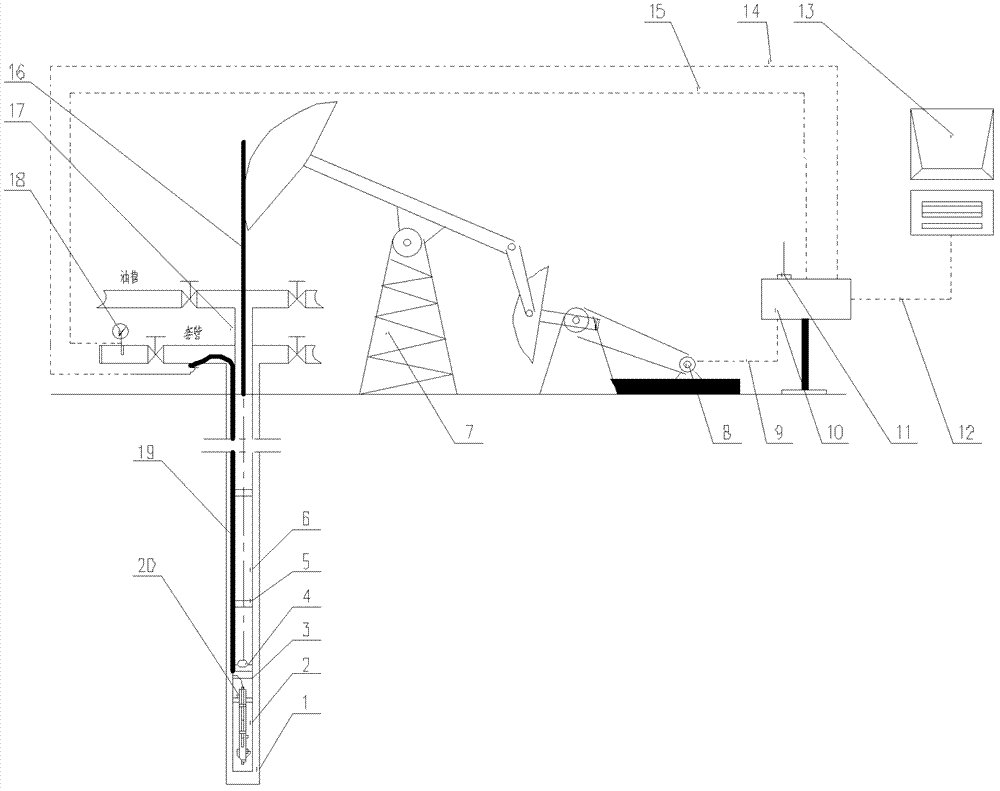

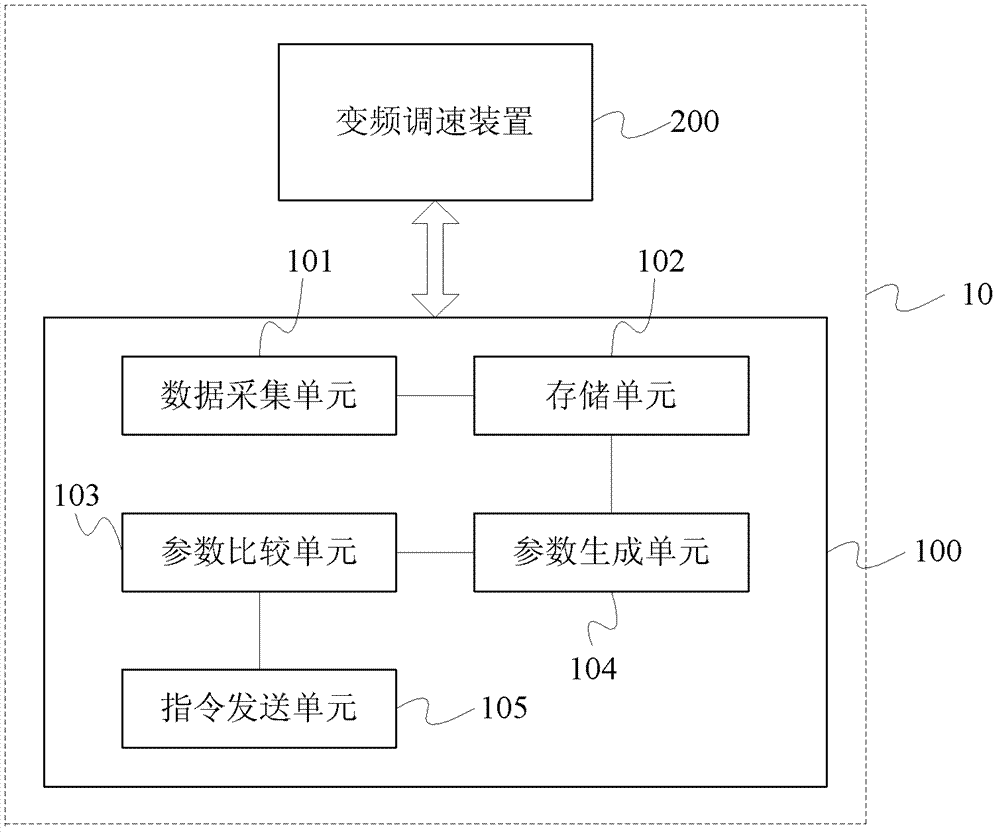

[0024] figure 1 It is a structural schematic diagram of a pumping unit closed-loop control system based on downhole multi-parameter real-time monitoring in an embodiment of the present invention, as figure 1 As shown, the pumping unit closed-loop control system includes:

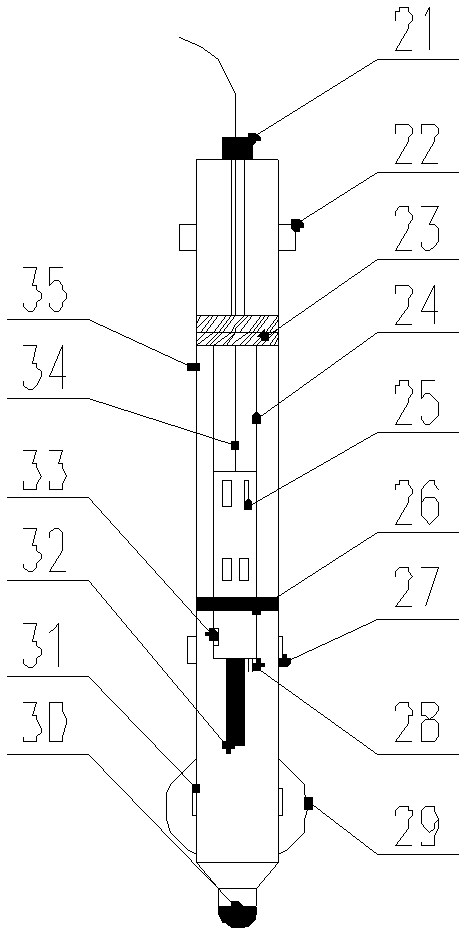

[0025] Casing 1; supporting cylinder 2, supporting cylinder coupling 3, oil pump 4, cable protector 5, tubing 6, pumping unit 7, ground data acquisition and control device 10, wellhead device 17 set in casing 1 , a single core logging cable 19 and a downhole multi-parameter tester 20 for testing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com