Wind shielding gravel mechanism not vertical to ground

A non-vertical, sand and stone technology, applied in the field of wind and sand retaining wall structures, can solve the problems of waste of manpower and material resources and loss of original equipment, and achieve the effect of weakening handling and avoiding erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

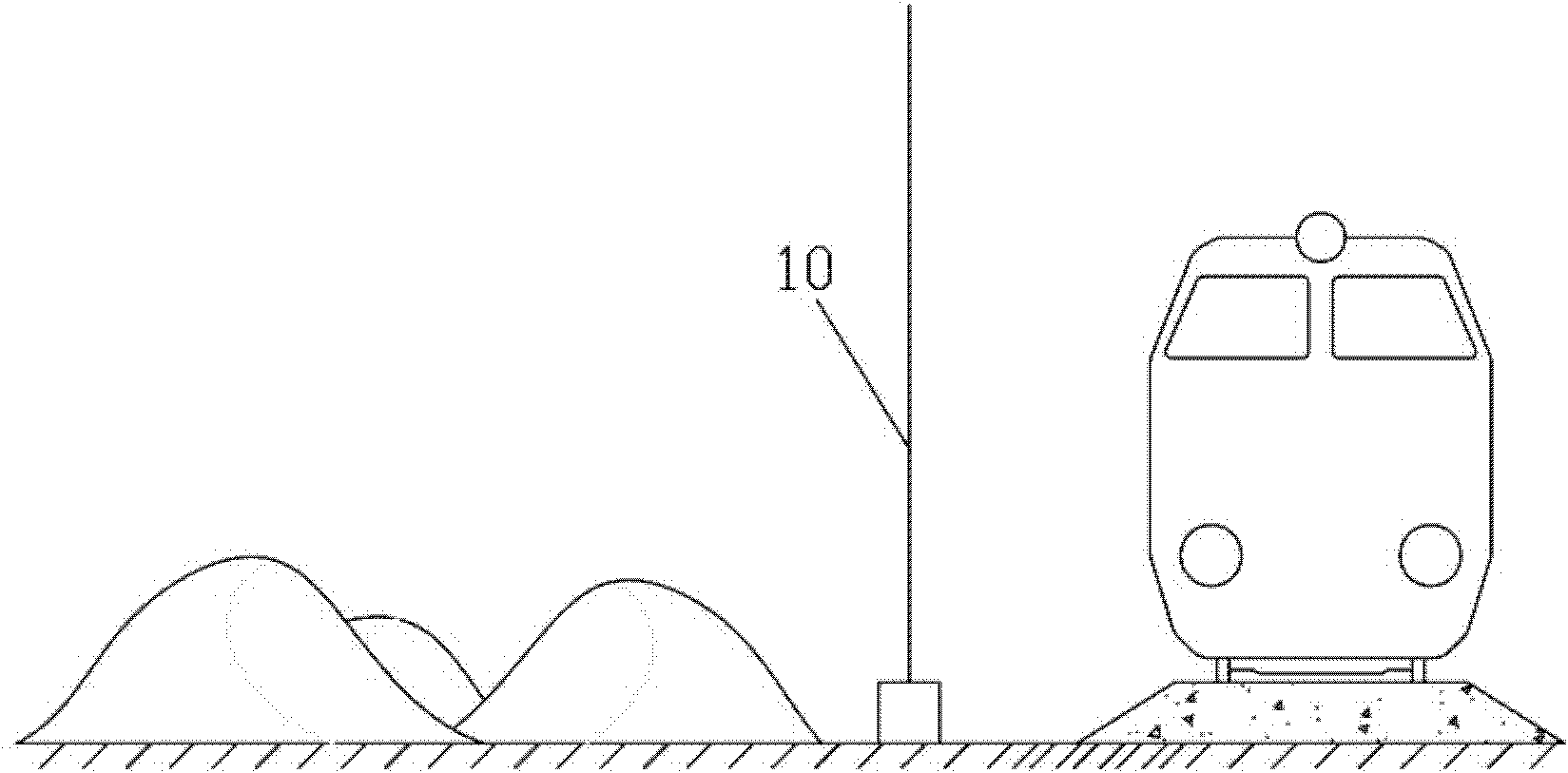

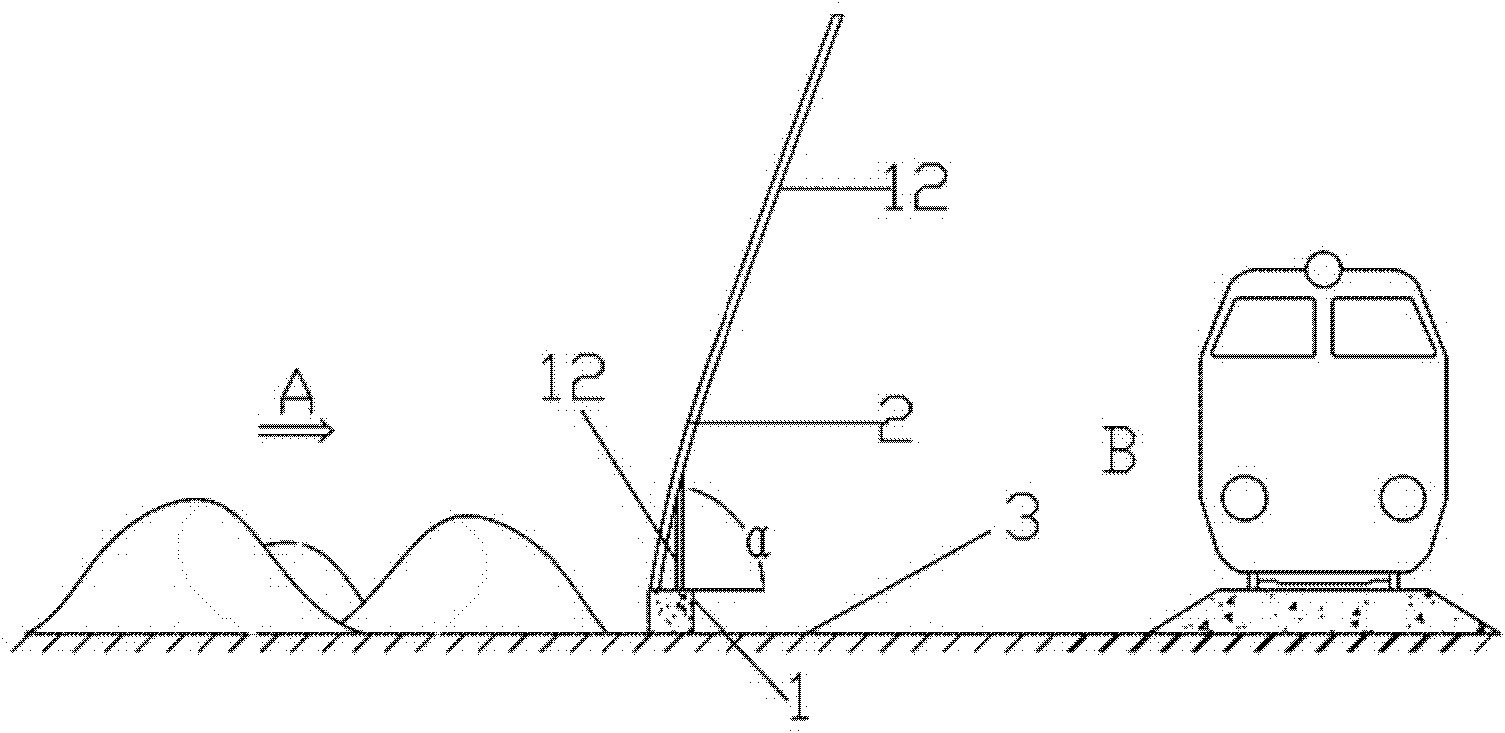

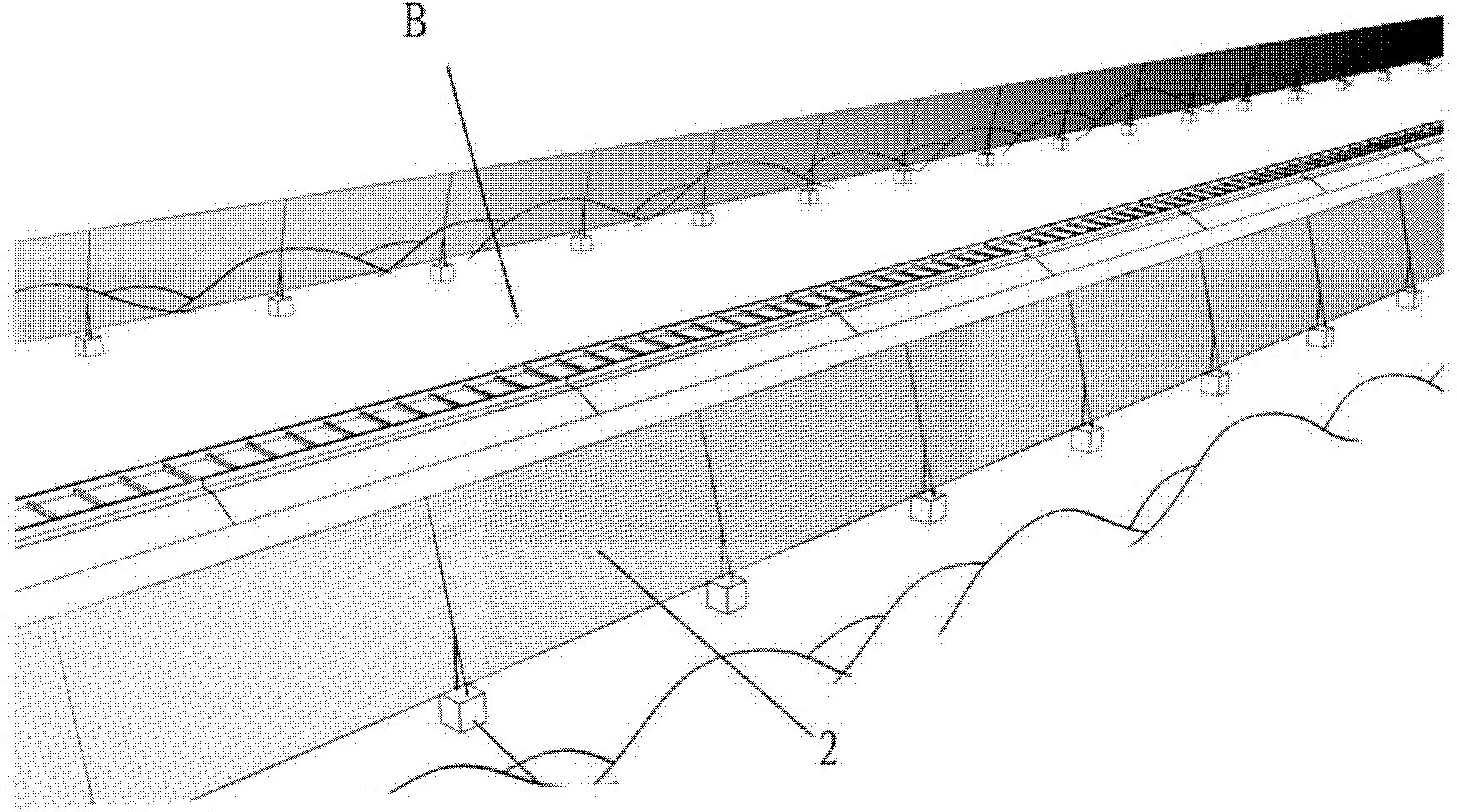

[0021] see Figure 2 ~ Figure 4 , which shows a preferred embodiment of a non-vertical ground windbreak sandstone mechanism of the present invention, including a base 1, a windbreak sandstone structure 2 installed on the base 1, and a windbreak sandstone structure 2 along the direction of wind movement (such as 2 and Figure 4 The direction A) shown in is inclined at an angle of 30 to 80 degrees with the installation surface 3 of the base 1 (such as figure 2 shown in the angle α), the angle α in this embodiment is the angle between the bottom tangent direction of the windshield sandstone structure 2 and the installation surface 3, of course, it is not difficult for those of ordinary skill in the art to understand , according to the characteristics of different geographical and geological environments, the windshield sandstone structure 2 of the present invention can be perpendicular to the installation surface 3 at the installation position, or even opposite to the movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com