Small food cutting machine

A cutting machine and food technology, applied in food science, metal processing, slaughtering, etc., can solve the problems of uniform slice thickness, unattractive slice appearance, and low manual cutting efficiency, so as to achieve uniform thickness, beautiful slice appearance, The effect of low labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

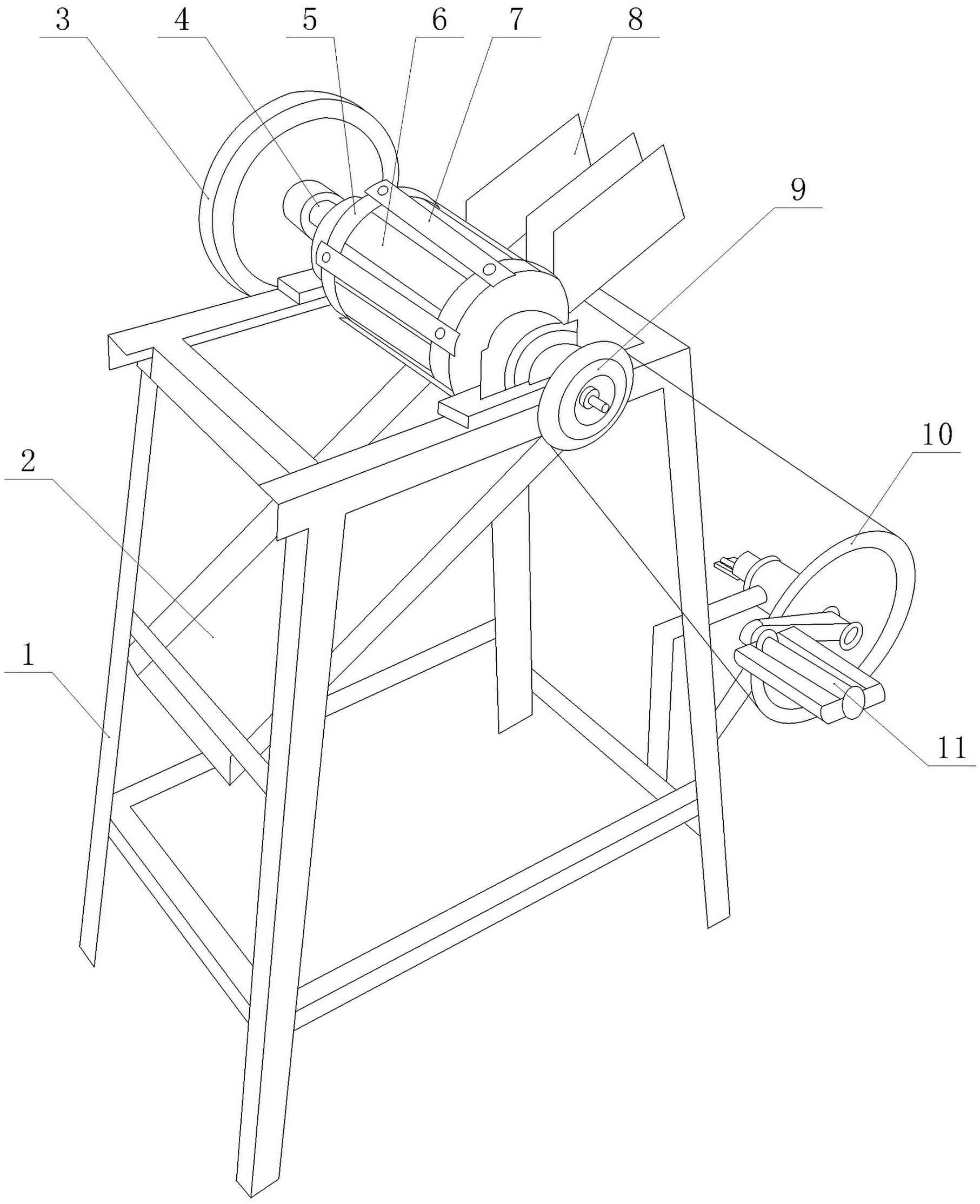

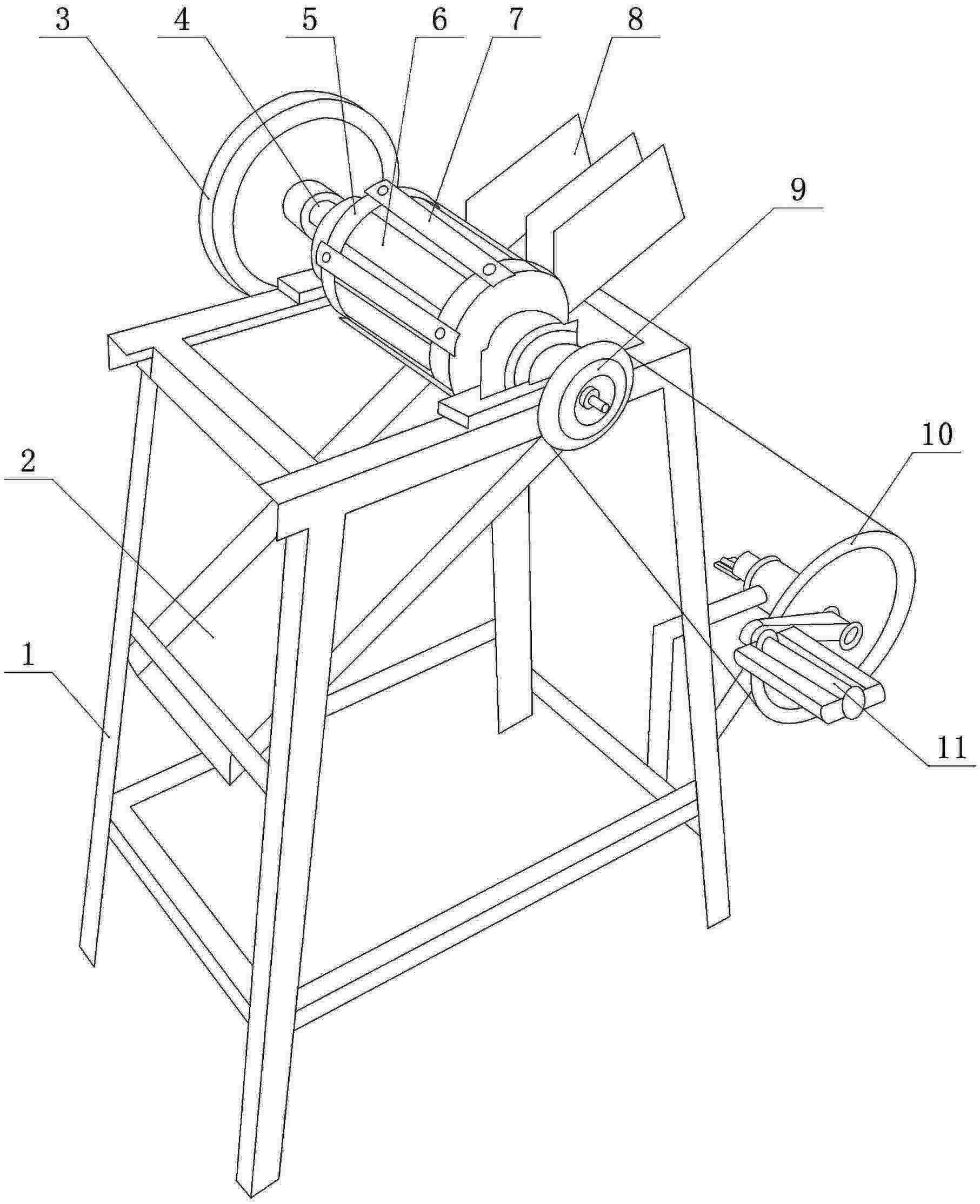

[0018] refer to figure 1 , a small food cutting machine, comprising a frame 1, a receiving trough 2 arranged in the frame 1, a cutting device arranged above the receiving trough 2, a feeding port 8 matched with the cutting device, and a transmission device , The cutting device is a rotary cutting tool, the two ends of the cutting cylinder in the cutting tool are respectively provided with a flywheel 9 and a pulley 3, and the crank sprocket 10 in the transmission device is connected with the flywheel 9 through a chain.

[0019] The cutting cylinder is provided with a central shaft 4, and the flywheel 9 and the belt pulley 3 are respectively arranged at the two ends of the central shaft 4, and the central shaft 4 is arranged on the frame 1 through a bearing seat.

[0020] The cutting cylinder includes a plurality of blades 7, an inner stopper 6 and a blade holder with cylindrical connecting seats 5 at both ends, and a plurality of blades 7 are evenly arranged on the outer surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com