Poly(butylene terephthalate) composition, preparation method, and products thereof

A kind of technology of butylene terephthalate and ethylene terephthalate, applied in the field of polymer compositions

Inactive Publication Date: 2011-12-28

SABIC INNOVATIVE PLASTICS IP BV

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, obtaining modified PBT compositions with desirable mechanical, thermal, and optical properties remains a challenge, especially when minor polymer components and / or impurities present in PET are not separated out prior to the conversion of PET to PBT

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-8

[0172] Examples 1-8. Molding compositions of modified PBT copolymers containing PVC

[0173] As shown below, Examples 1-8 illustrate the properties of the modified PBT copolymer composition:

Embodiment 1

[0174] Example 1: Modified PBT made from PET containing 115 ppm PVC.

Embodiment 2

[0175] Example 2: Modified PBT made from PET containing 287 ppm PVC.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Login to view more

Abstract

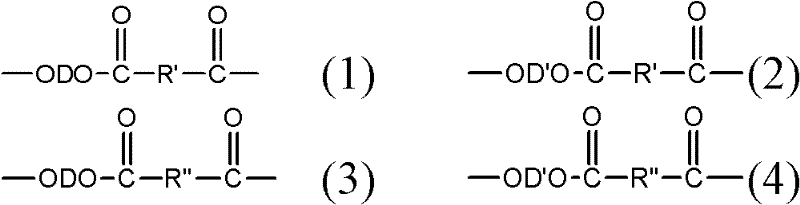

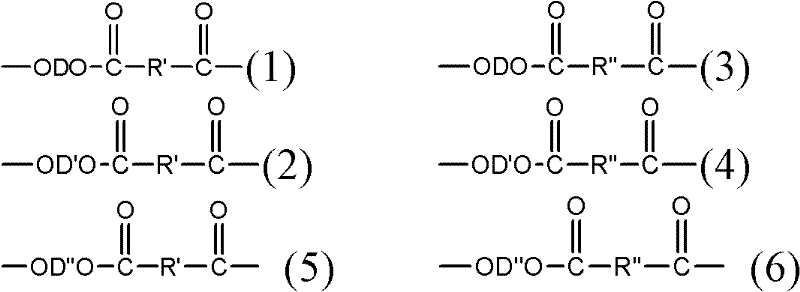

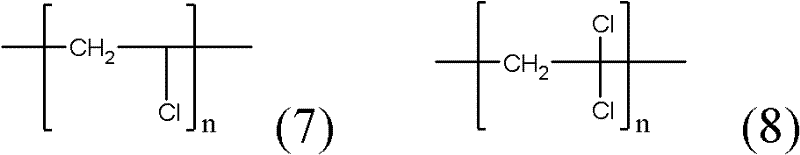

A composition comprising the following substances based on the total weight of the composition: 5 to 90wt.% modified poly(butylene terephthalate) copolymer, wherein (i) the modified poly(terephthalate) Butylene phthalate) copolymers derived from a first polymer comprising a poly(ethylene terephthalate) component in the presence of a second polymer, the poly(ethylene terephthalate) ) component is poly(ethylene terephthalate) homopolymer, poly(ethylene terephthalate) copolymer, or a combination thereof, and the second polymer is polyvinyl chloride, polyvinylidene Vinyl chloride, polyamide, polylactic acid, or combinations thereof, and (ii) said modified poly(butylene terephthalate) copolymer comprising: (a) at least one poly(ethylene terephthalate) alcohol ester) component, and (b) a member selected from the group consisting of: (a) at least one second polymer that is polyvinyl chloride, polyvinylidene chloride, polyamide, poly Lactic acid, or a combination thereof, (b) at least one residue derived from a second polymer, and (c) a combination thereof.

Description

Background of the invention [0001] The present invention relates to poly(butylene terephthalate) compositions, methods of preparation, and articles thereof. [0002] Thermoplastic molding compositions based on poly(butylene terephthalate) (PBT) are used in a variety of applications. While useful to many users, conventional PBT molding compositions generally cannot be made from PBT from recycled sources because of the unavailability of large quantities of post-consumer or post-industrial supplies of PBT waste material . Unlike PBT, poly(ethylene terephthalate) (PET) is produced in much larger quantities and is therefore easier to recycle from consumer waste. [0003] The increasing need to conserve non-renewable resources and more efficiently recycle underutilized waste PET has led to increased interest in incorporating PBT made from waste PET, known as modified PBT, into materials. However, obtaining modified PBT compositions with desirable mechanical, thermal, and optical ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): C08G63/183C08G63/89C08J11/24

CPCC08L27/18C08L67/04C08L77/00C08L69/00C08K5/0066C08K3/0033C08L77/02C08L67/02C08L27/06C08K3/013C08L2666/02

Inventor 克里斯滕.科胡恩-布里斯特

Owner SABIC INNOVATIVE PLASTICS IP BV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap