Plunger rod type steel ladle lifting mechanism

A lifting mechanism and plug-rod type technology, applied in the direction of mechanical equipment, engine components, valve details, etc., can solve the problems of increased gap between the guide groove and the slide bar, difficulty in lifting the slide bar, and failure to open and close the gate normally. To achieve the effect of smooth lifting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

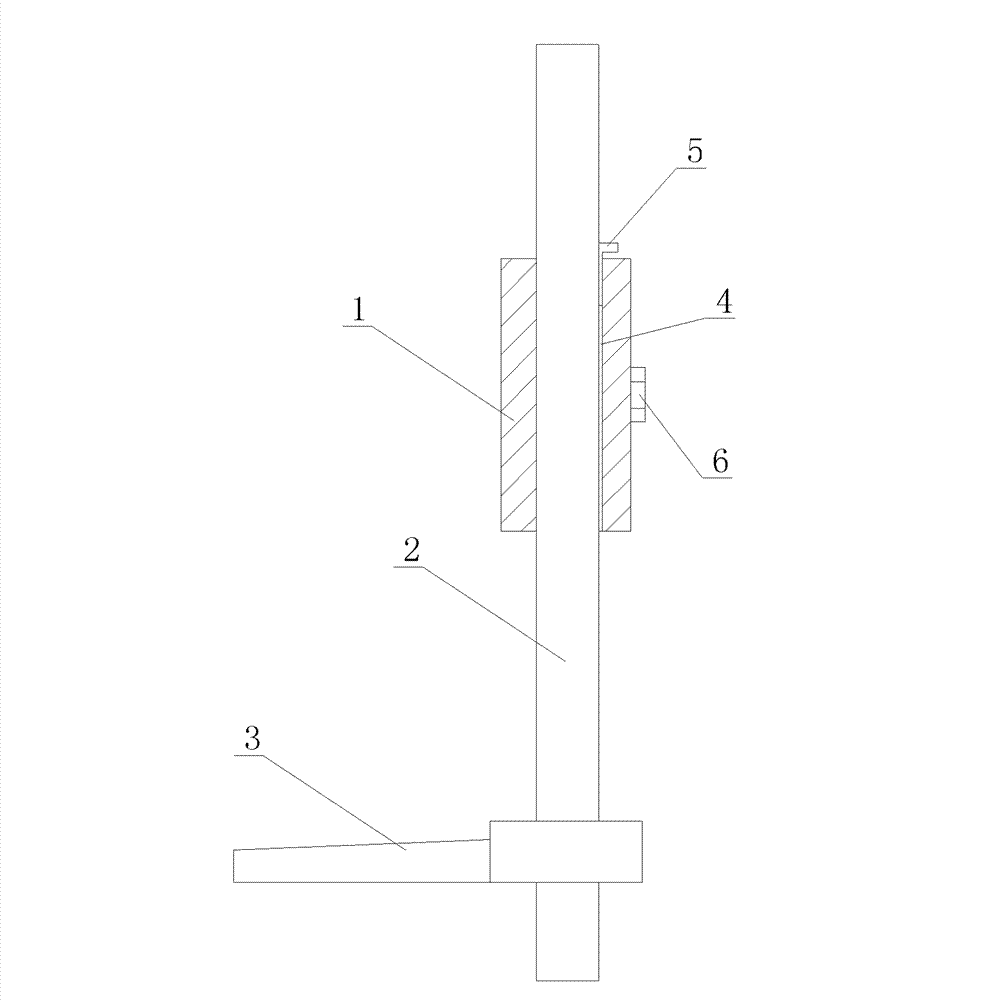

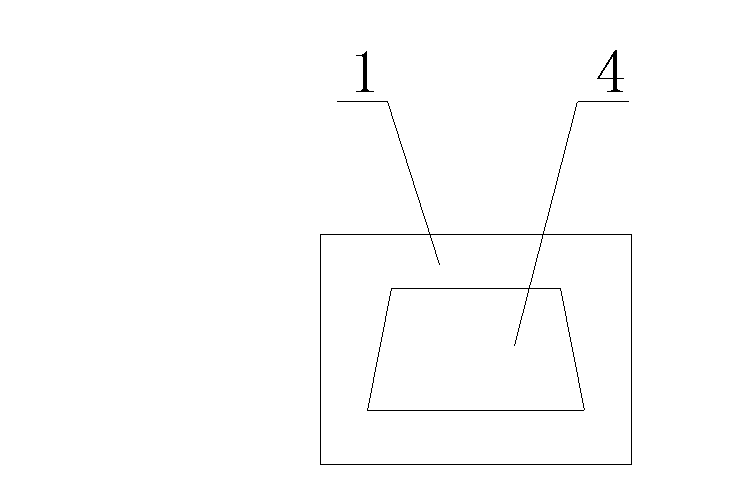

[0011] like figure 1 and figure 2 As shown, the plug-rod type ladle lifting mechanism includes a guide device 1, a slide rod 2 arranged on the guide device 1, and a pressing rod 3 arranged on the slide rod 2. The guide groove 4, the slide bar 2 adopts a trapezoidal structure, and the guide groove 4 adopts a trapezoidal structure corresponding to the slide bar 2. A pad iron 5 corresponding to the slide bar 2 is arranged in the guide groove 4 . The guide device 1 is provided with fastening bolts 6 corresponding to the slide bars 2 . The lifting operation of the slide bar is guaranteed to be smooth, and the center of the plug rod on the slide bar is easily aligned with the center of the nozzle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com