Mold for improving transmission uniformity of light guide plate

A technology of light guide plate and uniformity, applied in optical components, household appliances, other household appliances, etc., can solve the problem of high cost of mold making, and achieve the effect of simple processing and simple processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

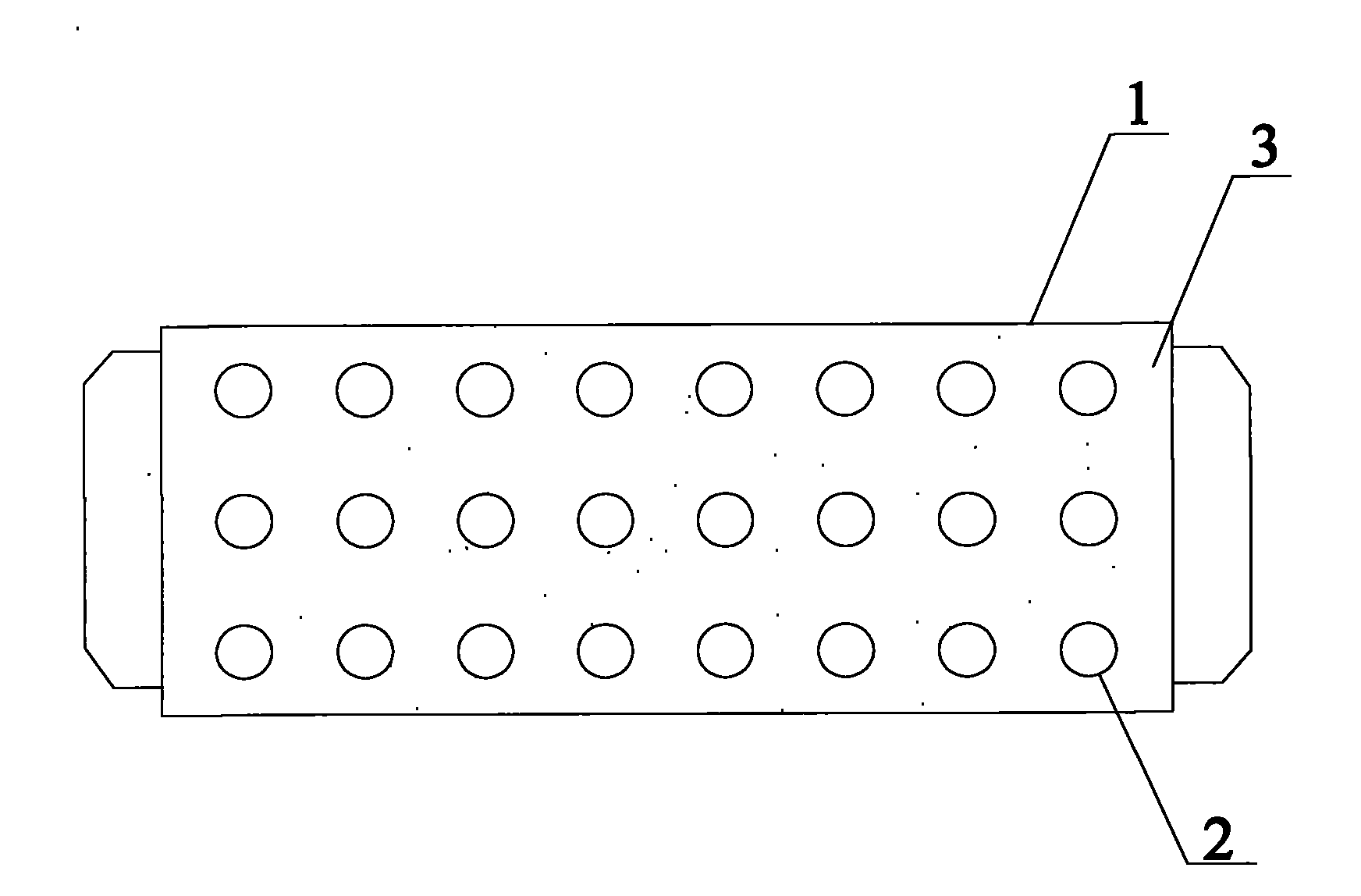

[0015] A mold for improving the uniformity of light transmission of a light guide plate, the structure of which is as follows figure 1 As shown, on the surface of the molded light guide plate mold workpiece 1, dot matrix 2 is processed in the region of the light-transmitting surface to be formed, and a layer of skin texture 3 is reprocessed in the dot matrix 2 area, and the light guide plate mold workpiece 1 is formed. The light area needs to process the required dot matrix 2 first, and then process the skin pattern 3, so that the light transmission of the formed light guide plate is more uniform. The dot matrix 2 plays the role of preliminary refraction of the light, and the striae 3 refracts the light that has been refracted by the dot matrix 2 again. The uniformity of the light after two refractions is much higher than that of the simple The refraction effect of lattice 2, therefore, the uniformity of light transmission of the light guide plate processed by using the mold c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com