Oscillator that can swing in a "u" shape

An oscillator and glyph technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to weld or cut, difficult operation, poor welding and cutting quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

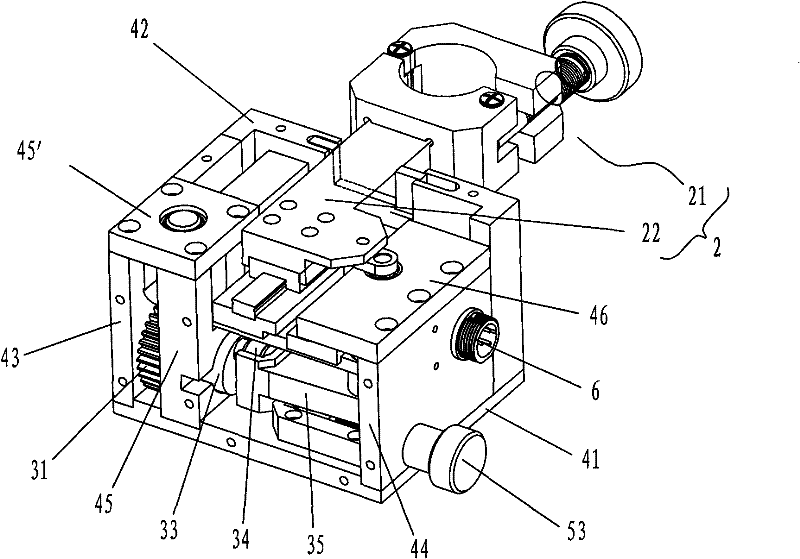

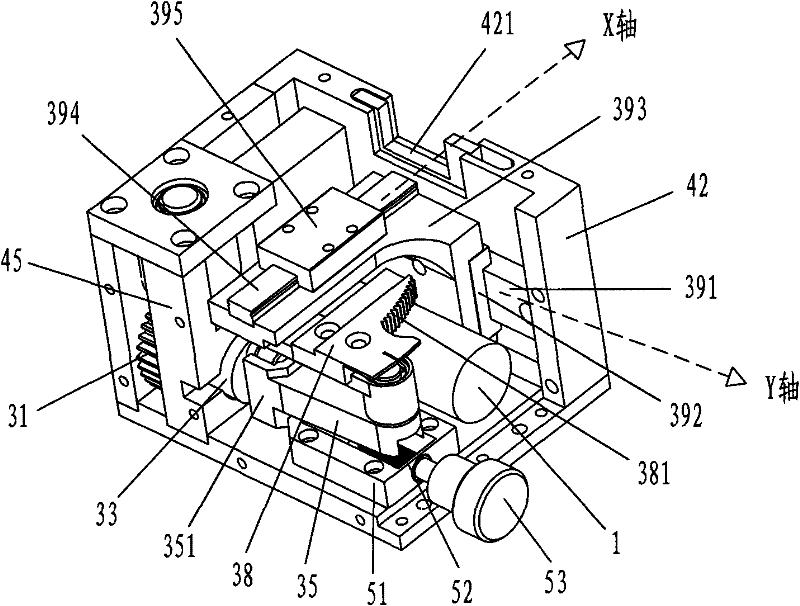

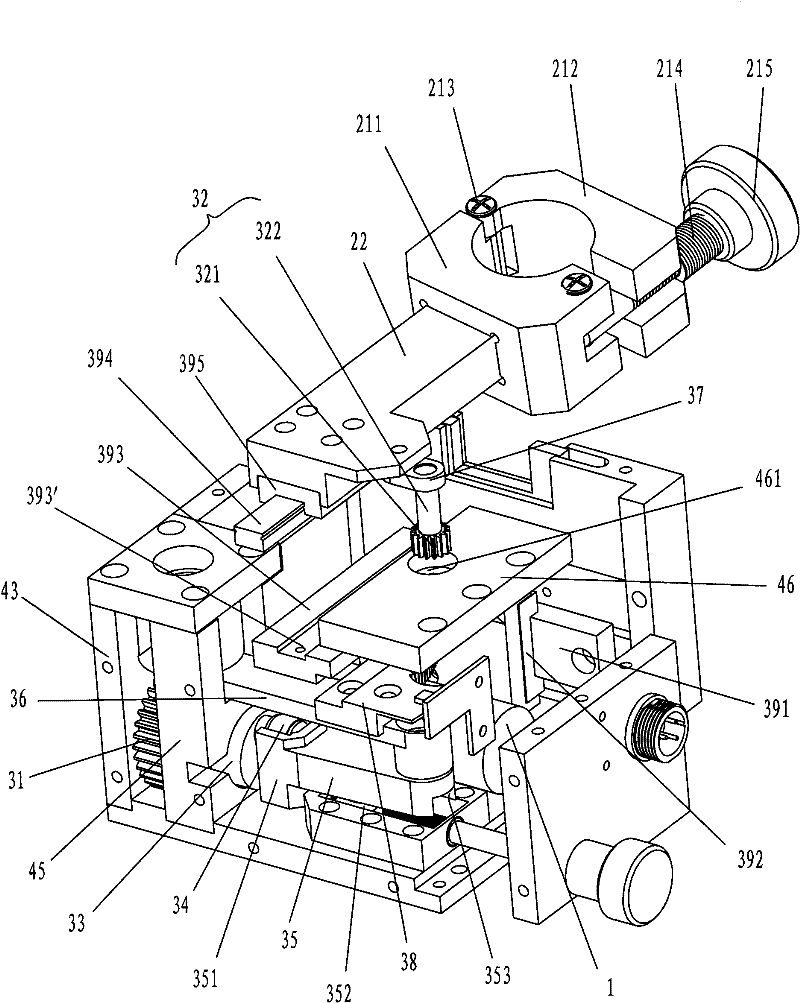

[0016] Please refer to the accompanying drawings Figure 1-3 . Among the figure, motor 1, clamping mechanism 2 (gun clip 21, gun clip connecting plate 22), transmission device (the first swing gear 31, the second swing gear 32, the swing eccentric wheel 33, the swing ring 34, the first swing lever 35 , the second swing lever 36, the third swing lever 37, the rotating gear 38), the slide guide seat 51, the adjustment screw 52, the adjustment handle 53, the first fixed plate 41, the second fixed plate 42, the third fixed plate 43, The fourth fixed plate 44 , the fifth fixed plate 45 , and the sixth fixed plate 46 .

[0017] As shown in the picture:

[0018] The present invention provides a "U" shaped oscillating oscillating device, including a motor 1, a clamping mechanism 2, a transmission device, and a first fixing plate 41, a second fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com