Mold for die casting machine of lead-acid storage battery plate grid

A technology for lead-acid batteries and die-casting machines, which is applied in the field of molds for lead-acid battery grid die-casting machines. Effects of grid quality problems, quality assurance, and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

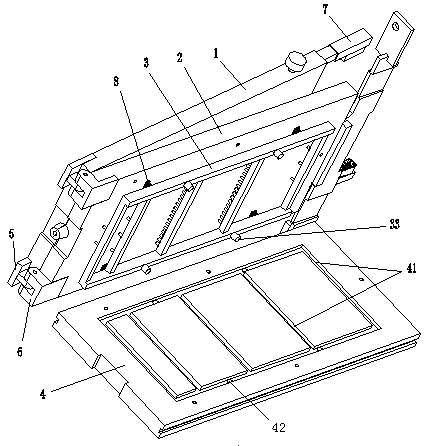

[0027] The structure of the mold of the present invention is described in detail below according to the accompanying drawings, wherein the end where the injection port of the mold 104 is set is the rear end of the mold, the opposite end is the front end, and the two sides between the rear end and the front end of the mold are sides. Set the up and down directions according to the use state of the mold, that is, the base plate is located below the fixed plate.

[0028] Such as image 3 , Figure 4 As shown, the mold of the present invention includes a movable mold 1 and a fixed mold; the fixed mold includes a fixed template 2, a base plate 4 and an ejector device 3, and the base plate 4 is covered on the lower surface of the fixed template 2, and the ejector device 3 is buckled on the In the accommodating cavity provided on the upper surface of the bottom plate 4. The bottom plate 4 and the fixed formwork 2 are fixed by screws, see Figure 7 , the hole 22 on the lower surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com