Tooling for tire die forging to manufacture gear blanks

A gear blank and tire die forging technology, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of incomplete filling of gear blanks and increased production costs, and achieve structural Simple, complete filling, and the effect of increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The tool for manufacturing gear blanks by tire die forging of the present invention will be further described in detail below through specific examples.

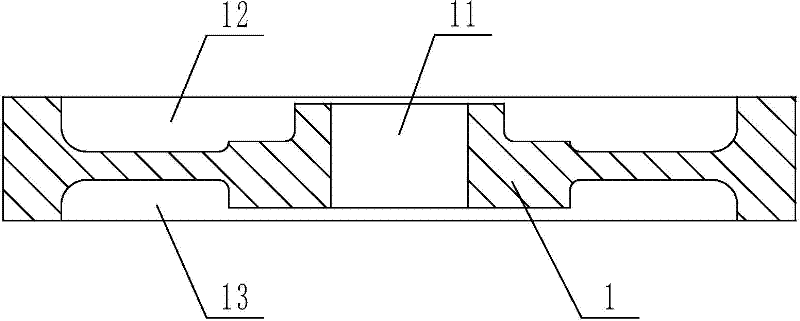

[0016] Tire die forging tooling for manufacturing gear blanks, including a cylindrical lower die 2, a cylindrical upper die 3 and a jacket 4, such as figure 2 As shown, the lower end surface of the lower mold 2 is a plane, and the upper end surface of the lower mold 2 is provided with a large annular boss 21 matched with the upper end surface of the gear 1, and the large annular boss 21 is stepped; as image 3 As shown, the upper end face of the upper die 3 is a plane, and the lower end face of the upper die 3 is provided with a small annular boss 31 that matches the lower end face of the gear 1; Figure 4 As shown, the outer casing 4 is a ring column, the inner diameter of the outer casing 4 matches the diameters of the lower mold 2 and the upper mold 3, and the inner wall of the outer casing 4 is provided with a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com