A kind of preparation method of spherical cyclodextrin resin particles

A technology of resin particles and cyclodextrin, which is applied in the field of preparation of cyclodextrin resin particles, can solve the problem of low selectivity of phenol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

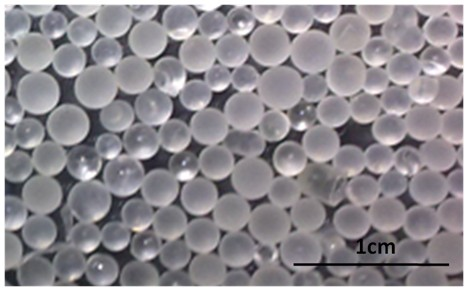

[0027] Example 1 Synthesis of spherical α-cyclodextrin resin particles

[0028] Add 14.5 grams of α-cyclodextrin, 7.5 milligrams of sodium borohydride (potassium borohydride or potassium aluminum hydride) and 18.9 milliliters of water into a 500-ml three-neck flask, stir for a while to make the cyclodextrin into a slurry shape, slowly add 18.0 grams of epichlorohydrin (diisocyanate or 1,3-bis(azidomethyl)benzene) and stir for a period of time, then add 16.2 milliliters of sodium hydroxide aqueous solution (40wt%) dropwise to in the mixture. After dripping, stir again for 20 minutes, finally add 250 milliliters of liquid paraffin (or cyclohexane), and react for 20 hours. During the reaction, the stirring speed of mechanical stirring is controlled at 200 revolutions per minute, and the temperature is controlled at 35° C. After the reaction, the cyclodextrin resin particles were filtered out, washed with water and ethanol, filtered, and finally dried at 60°C to obtain the α-cycl...

Embodiment 2

[0029] Example 2 Synthesis of spherical β-cyclodextrin resin particles

[0030] Add 14.5 grams of β-cyclodextrin, 7.5 milligrams of sodium borohydride and 14.5 milliliters of water into a 500 milliliter three-neck flask, stir for a while to make the cyclodextrin into a slurry, and slowly add 20.2 grams of epichlorohydrin After stirring for a while, 16.2 ml of aqueous sodium hydroxide solution (40 wt %) was added dropwise to the mixture. After dripping, stir again 20 minutes, add the liquid paraffin of 250 milliliters at last, react 20 hours, the stirring speed of mechanical stirring during reaction is controlled at 200 revs per minute, and temperature is controlled at 35 ℃. After the reaction, the cyclodextrin resin particles were filtered out, then washed with water and ethanol, filtered, and finally dried at 60°C to obtain the β-cyclodextrin resin, whose electron micrograph is as follows: figure 2 shown.

Embodiment 3

[0031] Example 3 Synthesis of spherical γ-cyclodextrin resin particles

[0032] Add 14.5 grams of γ-cyclodextrin, 7.5 mg of sodium borohydride and 21.8 ml of water into a 500 ml three-neck flask, stir for a while to make the cyclodextrin into a slurry, and slowly add 20.8 grams of epichlorohydrin After stirring for a while, 16.2 ml of aqueous sodium hydroxide solution (40 wt %) was added dropwise to the mixture. After dripping, stir again 20 minutes, add 250 milliliters of liquid paraffin at last, react 20 hours, the stirring speed of mechanical stirring during reaction is controlled at 200 revs per minute, and temperature is controlled at 35 ℃. After the reaction is over, the cyclodextrin resin particles are filtered out, washed with water and ethanol, filtered, and finally dried at 60°C to obtain the γ-cyclodextrin resin, whose electron micrograph is as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com