Online measuring method of diameter of grinding wheel of high-force powerful shape-followup snagging machine

A measurement method and a powerful technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problem that the return signal cannot be received, the working environment of the barren mill is harsh, and the outer circle of the grinding wheel is hot and red hot Status and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

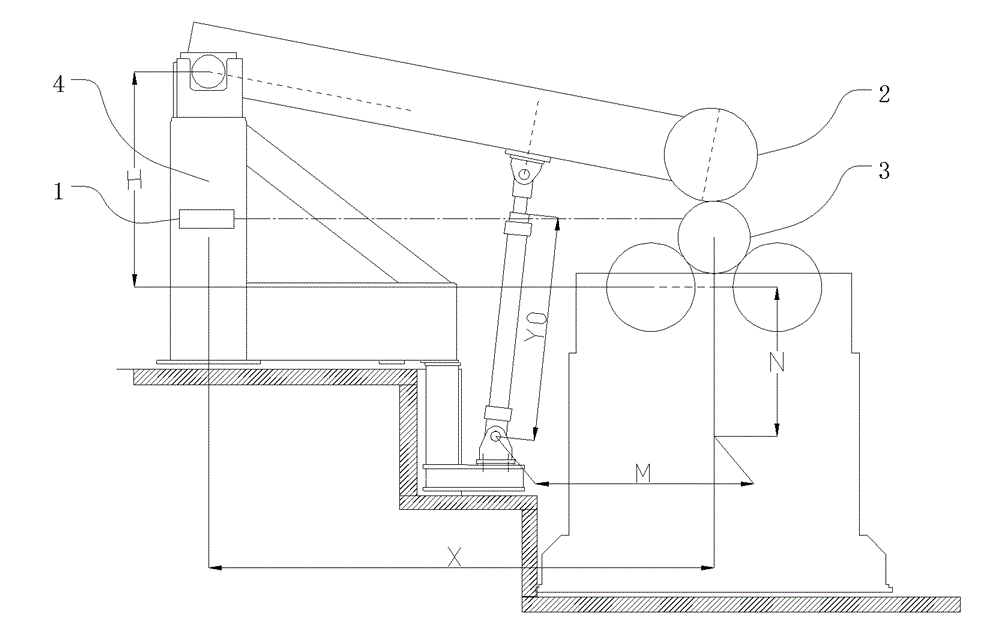

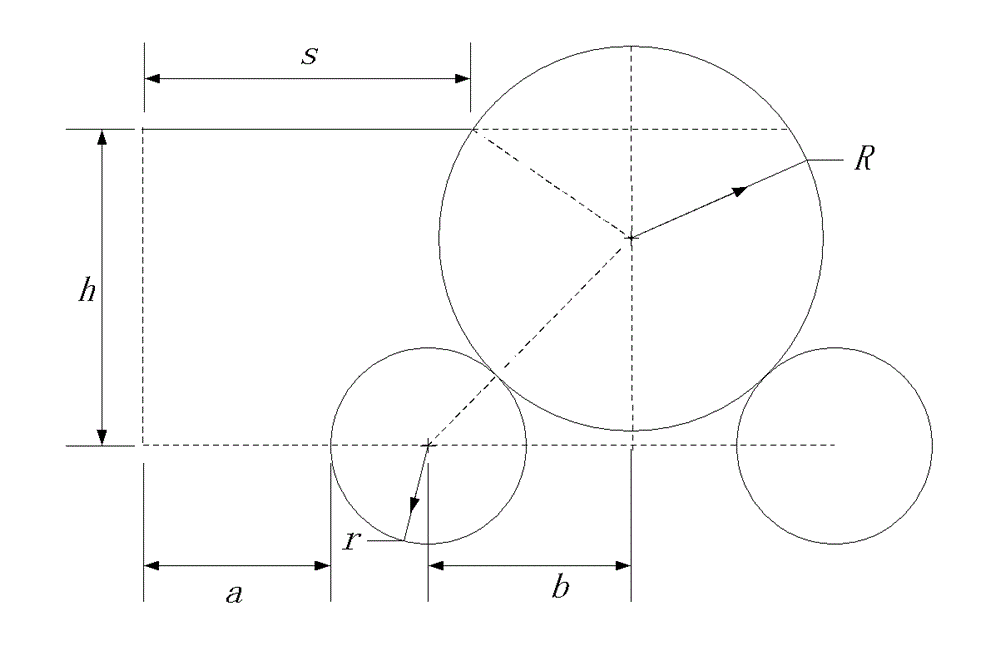

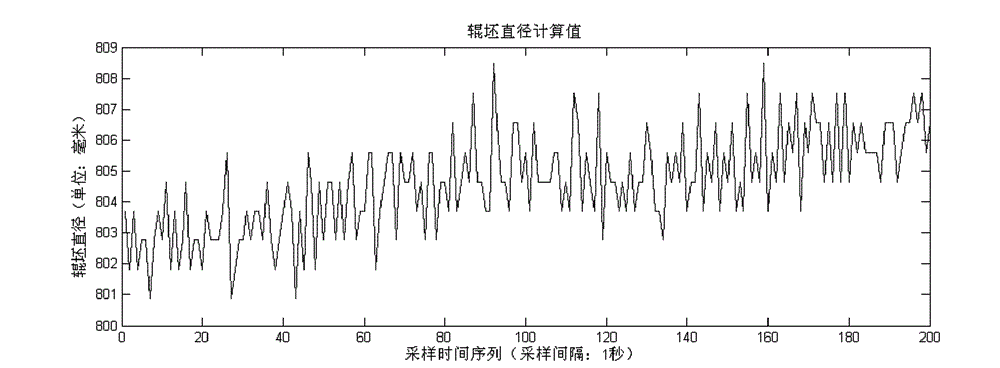

[0069] The present invention provides an on-line measurement method for the diameter of a grinding wheel of a high-speed powerful conformal rough grinding machine. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0070] The concrete steps of this method are:

[0071] 1) Hardware configuration and installation: Based on the specifications of the mill and the on-site production environment, there are corresponding requirements for various indicators of the laser sensor, the most important of which are range, accuracy, frequency and stability. This solution uses a domestic laser displacement sensor with a range of 0.2~70m, an accuracy of ±1mm, and a maximum frequency of 10Hz.

[0072] The high-precision displacement measurement laser sensor 1 is installed under the support arm 4 of the waste mill, which not only avoids sparks splashing around during grinding, but also avoids the increase of errors caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com