A method for automatic cleaning and drying of a mop and a double-tube mop bucket for implementing the method

A technology for automatic cleaning and mop buckets, applied in the field of mop buckets, can solve the problems of discomfort, poor wringing of wet mop sewage, and difficulty in wringing out, so as to improve the quality of life, reduce labor intensity, and ingenious design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

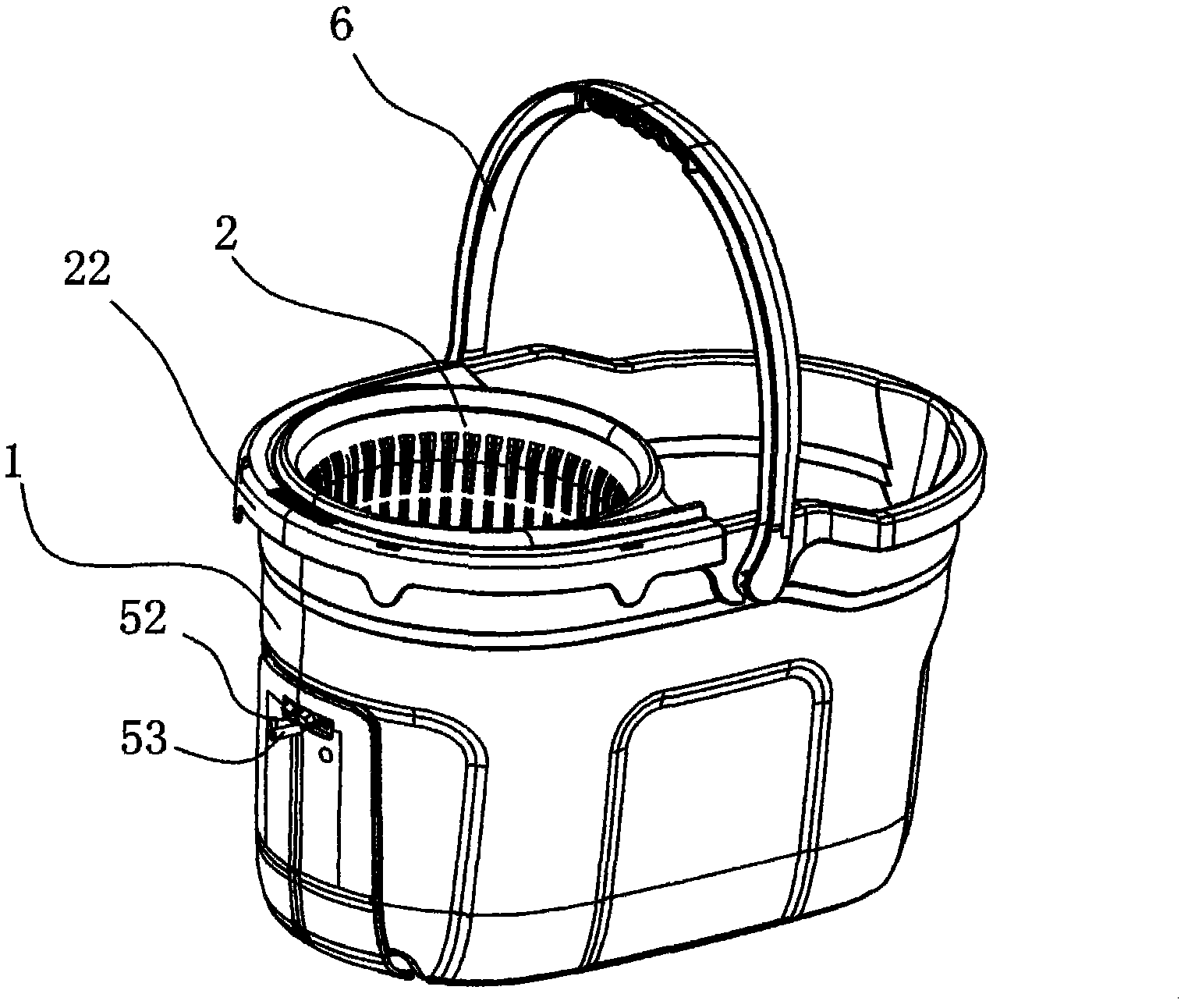

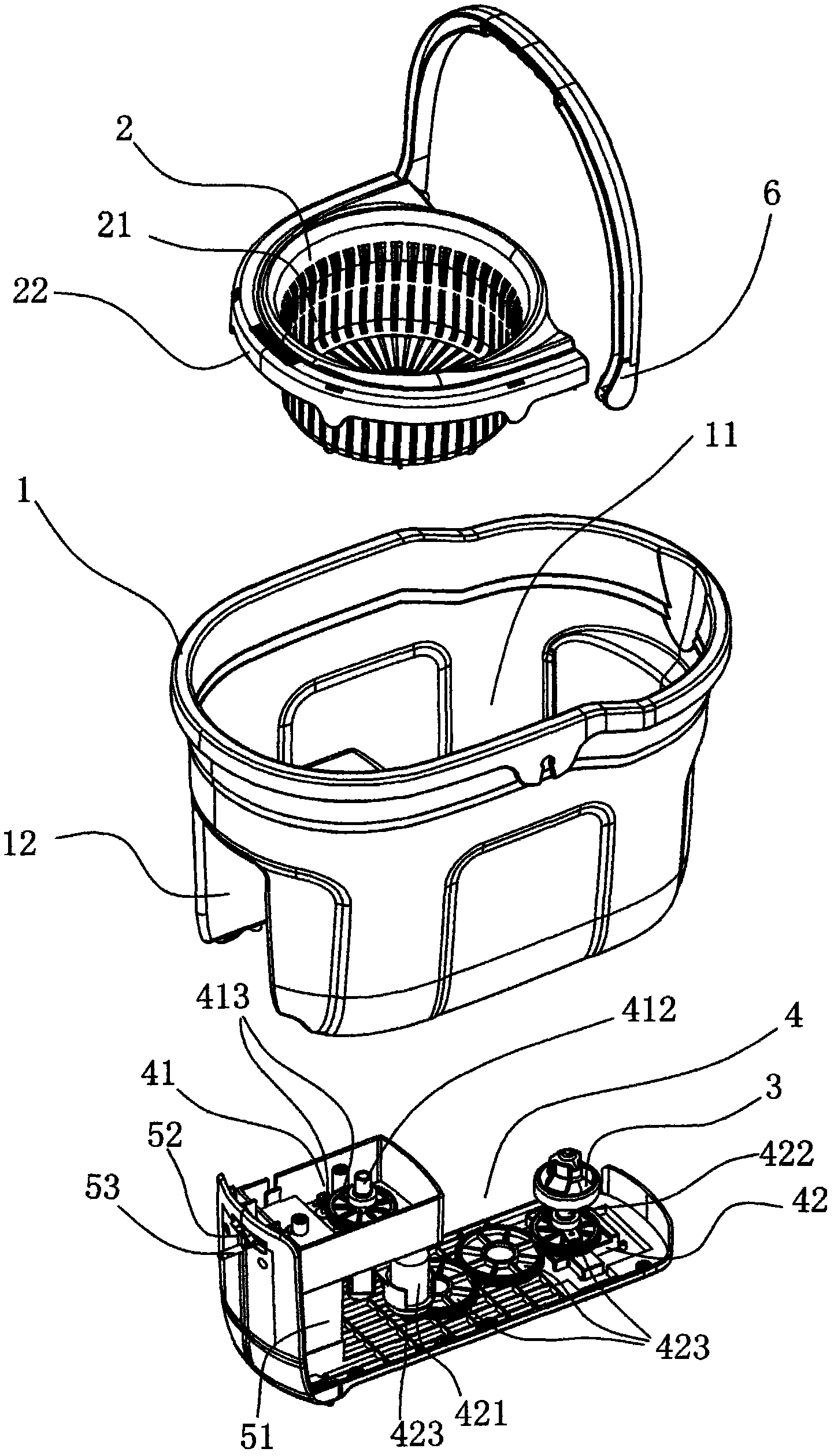

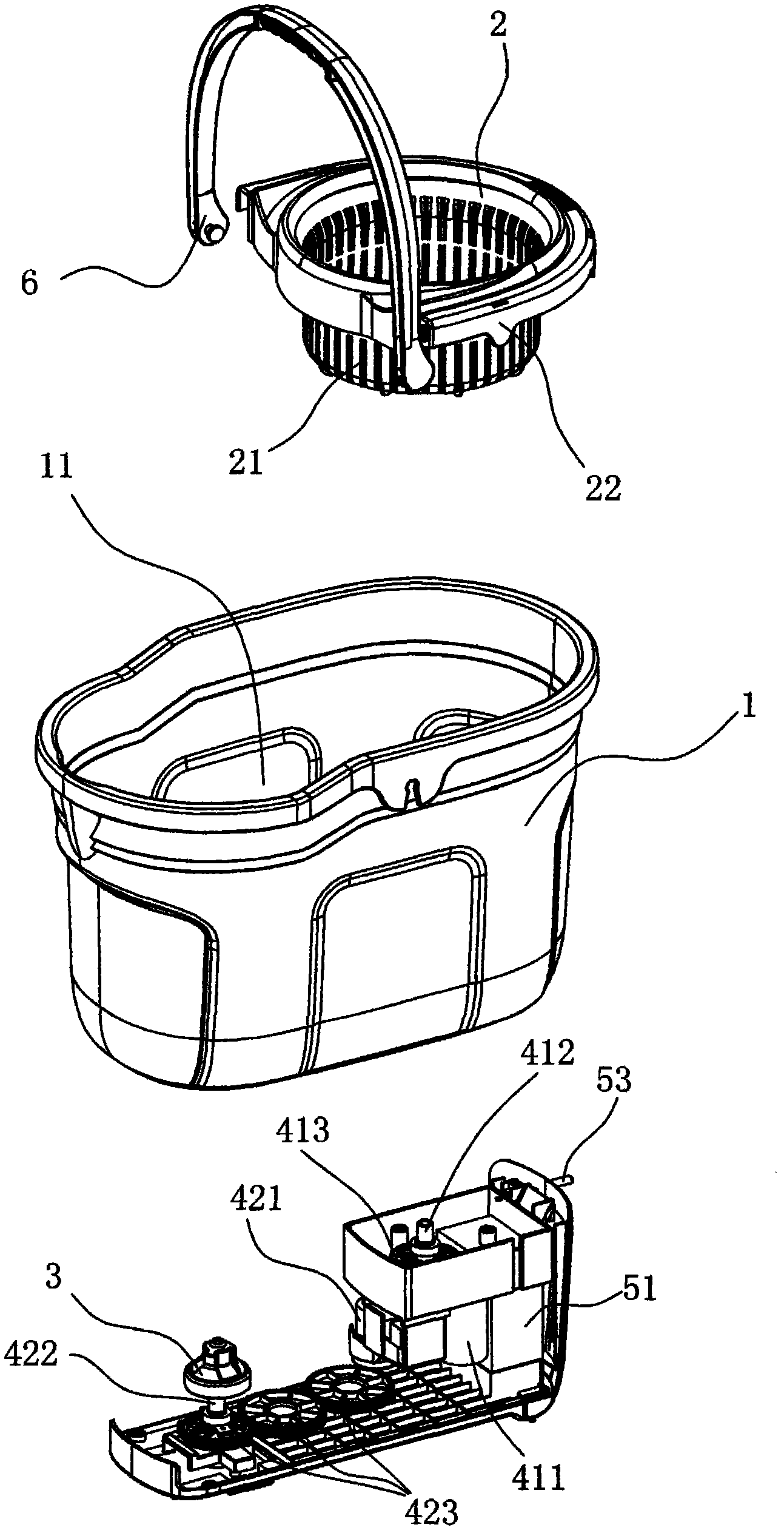

[0027] Example: see Figure 1 to Figure 4 , the present invention a kind of mop automatic cleaning and the method for de-drying, it comprises the following steps:

[0028] (1) Prepare a bucket body 1, the bucket body 1 includes an upper water-filling space 11 and a lower driving space 12, and the water-filling space 11 and the driving space 12 are sealed and isolated;

[0029] (2) A water filter screen 2 that can rotate and move up and down and a spiral body 3 that can rotate and move up and down are set in the water-filled space 11 of the barrel body 1, and the water filter 2 is located in the water-filled space 11- The spiral body 3 is located at the bottom of the other side of the water holding space 11. The high-speed rotation of the spiral body 3 in the water body drives the water body to oscillate and vibrate so as to clean the dirty mop placed in the water body. The sieve 2 rotates at a high speed so that the moisture on the wet mop placed in the water filter 2 is dehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com