pipe clamping ring

A technology for clamping rings and pipes, which is applied in the field of clamping elements of pipeline fittings, pipeline fittings and pipeline joints, and can solve problems such as impracticability and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

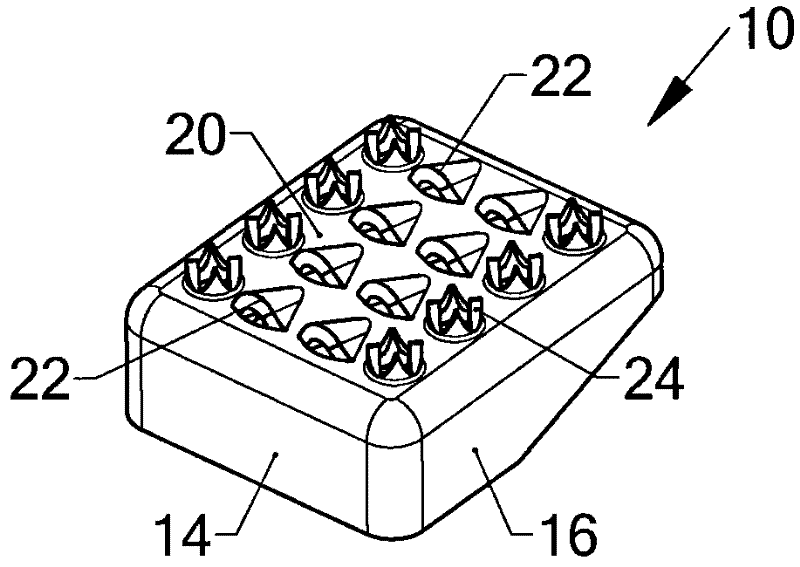

[0031] figure 1 and figure 2 A clamping element 10 made of sheet steel is shown. figure 1 The interior of the clamping element is shown, wherein all walls 12 , 14 , 16 , 18 of the element can be seen. exist figure 2 In , an array of two different sizes of teeth can be seen. The angled side walls 12, 16 give the element 10 a wedge-shaped configuration. The exposed top exterior surface 20 is steel plate which is integral with all four walls.

[0032] The clamping element 10 is provided with an array of large clamping teeth 22 and small clamping teeth 24 . The sharp sides of all teeth 22 , 24 face the higher of the two end walls 14 , the larger teeth 22 projecting more from the surface of the top outer surface 20 than the smaller teeth 24 .

[0033] With reference to the remaining figures, like reference numerals are used to denote like parts.

[0034] image 3 Clamping ring 26 is shown for use in reference to Figure 4 used in the pipe fittings described. The ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com