A seamless splicing display device and a seamless splicing method thereof

A seamless splicing and display technology, applied in the direction of identification devices, instruments, etc., to achieve the effect of eliminating splicing gaps, low cost, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments and examples of the present invention will be described in detail below in conjunction with the accompanying drawings. The described specific embodiments are only used to explain the present invention, and are not intended to limit the specific embodiments of the present invention.

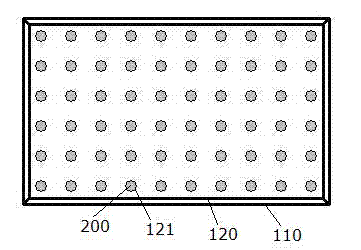

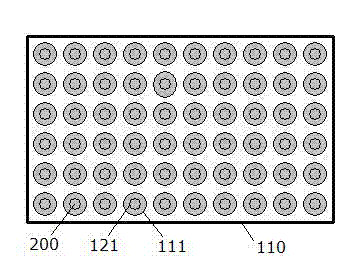

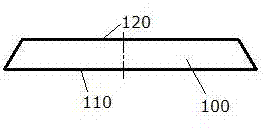

[0027] A seamless splicing display device of the present invention adopts mold opening to inject and mold a trapezoidal plastic box 100 with a large end and a small end, such as figure 1 As shown, one of its specific implementation methods, taking the conical mounting hole and the conical light guide column as an example, such as Figure 4 As shown, several conical installation holes with one end larger and the other end smaller are provided inside the box body 100 along the axis direction of the box body 100 or along the direction vertical to the display panel; wherein, the orifice 111 at the large end of the installation hole is arranged in the trapezoidal box body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com