Tower fan air channel swing mechanism

A technology of rotating mechanism and air duct, applied in the field of rotating mechanism of tower fan air duct, can solve the problems such as the influence of fuselage rotation on safety, poor structural strength, unreasonable structure, etc., to avoid the hidden danger of long-term torsional wear, improve reliability, reduce load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The novelty of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

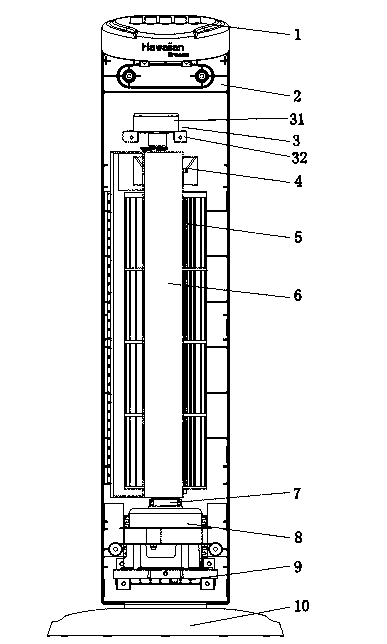

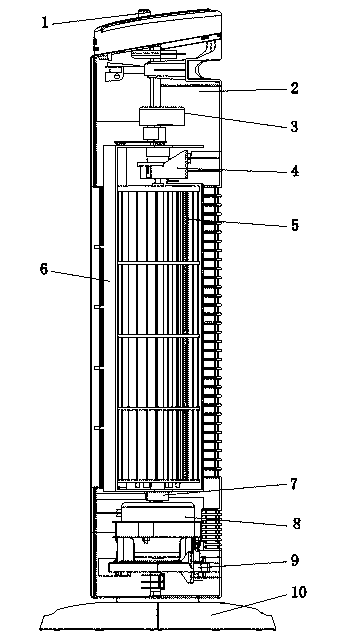

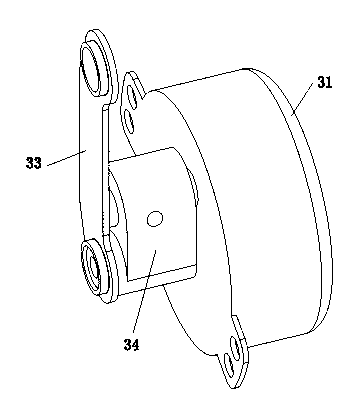

[0021] Such as Figures 1 to 9 As shown, it is a tower fan air duct rotation mechanism, including a casing 2, a control panel 1 arranged at the upper end of the casing 2, a wind wheel bearing assembly 4, a wind wheel 5, an air duct 6, a driving motor 8 and a base 10 The casing 2 includes a front casing 22 and a rear casing 21 that cooperate with each other, and an outlet grille is arranged on the front casing 22; an upper shaft 51 is arranged on the upper end of the wind wheel 5, and a lower shaft is arranged on the lower end The shaft 52 and the wind wheel 5 are located in the air duct 6; the feature of the present invention is that it also includes a swing mechanism 3, and the swing mechanism 3 is installed above the inside of the casing 2, close to the control panel 1, thus shortening the distance between the control panel and the swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com